Preparation method of dried garlics

A technology of garlic and garlic cloves, applied in food science, preservation of fruits/vegetables through dehydration, etc., can solve the problems of reduced allicin retention rate, reduced biological activity, etc., and achieves uniform drying moisture distribution, simple processing process, and high drying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of preparation method of dried garlic, its process flow chart is as follows figure 1 Specifically, it includes the following steps:

[0049] (1) Garlic pretreatment: take garlic with no residue, no insects, no rot, and peel off the garlic, and select garlic cloves with similar sizes;

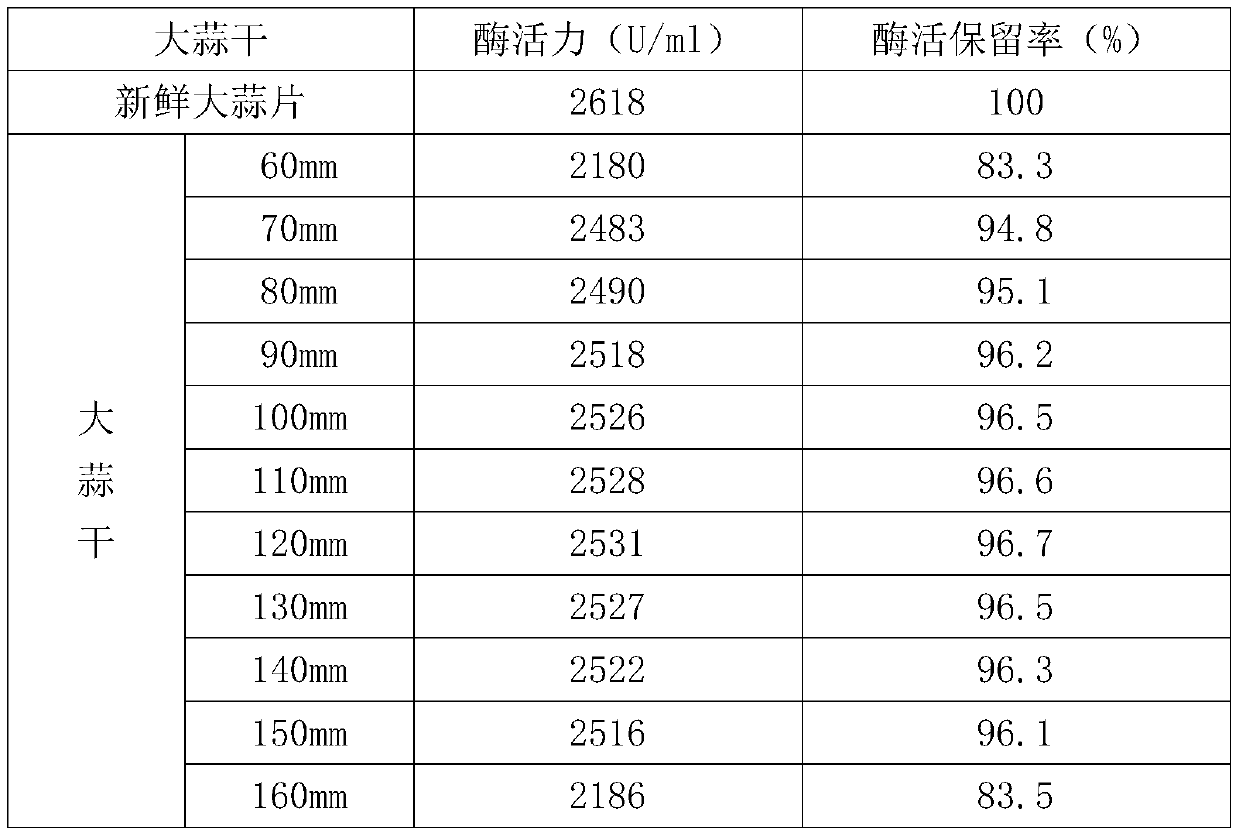

[0050] (2) Pre-drying: spread the garlic cloves evenly in the polypropylene container, then place the polypropylene container covered with garlic cloves on the transmission belt, and send it to the hot air-radio frequency drying system, set the distance between the two plates to 90mm, and turn on the radio frequency Turn off the radio frequency after 6 minutes, turn on the hot air system, the temperature of the hot air is 50°C, turn on the hot air system for 12 minutes, and then turn it off to obtain pre-dried garlic cloves with a moisture content of 31%;

[0051] (3) Variable temperature and pressure difference puffing: spread the pre-dried garlic cloves evenly on the screen of t...

Embodiment 2

[0053] A preparation method of dried garlic, comprising the following steps:

[0054] (1) Garlic pretreatment: take garlic cloves without residue, insects, and rot, and peel them, and choose garlic cloves with similar sizes.

[0055] (2) Pre-drying: spread the garlic cloves evenly in the polypropylene container, then place the polypropylene container covered with garlic cloves on the conveyor belt, and send it to the hot air-radio frequency drying system, set the distance between the two plates to 100mm, and turn on the radio frequency Turn off the radio frequency after 6 minutes, turn on the hot air system, the temperature of the hot air is 60°C, turn on the hot air system and turn it off after 12 minutes to obtain pre-dried garlic cloves with a moisture content of 30.5%;

[0056] (3) Puffing with variable temperature and pressure difference: spread the pre-dried garlic evenly on the screen of the expansion tube of the variable temperature and pressure difference puffing mach...

Embodiment 3

[0058] A preparation method of dried garlic, comprising the following steps:

[0059] (1) Garlic pretreatment: take garlic with no residue, no insects, no rot, and peel off the garlic, and select garlic cloves with similar sizes;

[0060] (2) Pre-drying: spread the garlic cloves evenly in the polypropylene container, then place the polypropylene container covered with garlic cloves on the conveyor belt, and send it to the hot air-radio frequency drying system, set the distance between the two plates to 70mm, and turn on the radio frequency After 3 minutes, turn off the radio frequency, turn on the hot air system, the temperature of the hot air is 55°C, turn on the hot air system and turn it off after 10 minutes, and obtain pre-dried garlic cloves with a moisture content of 40%;

[0061] (3) Variable temperature and pressure difference puffing: spread the pre-dried garlic cloves evenly on the screen of the expansion tube of the variable temperature and pressure difference puffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com