Extraction method of garlic essential oil capable of reducing solubility of cholesterol in micelle

A technology of garlic essential oil and extraction method, which is applied in the direction of essential oil/spice, fat production, etc., can solve the problems of low extraction temperature, high cost, high content of soluble impurities, etc., and achieve the effect of reducing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

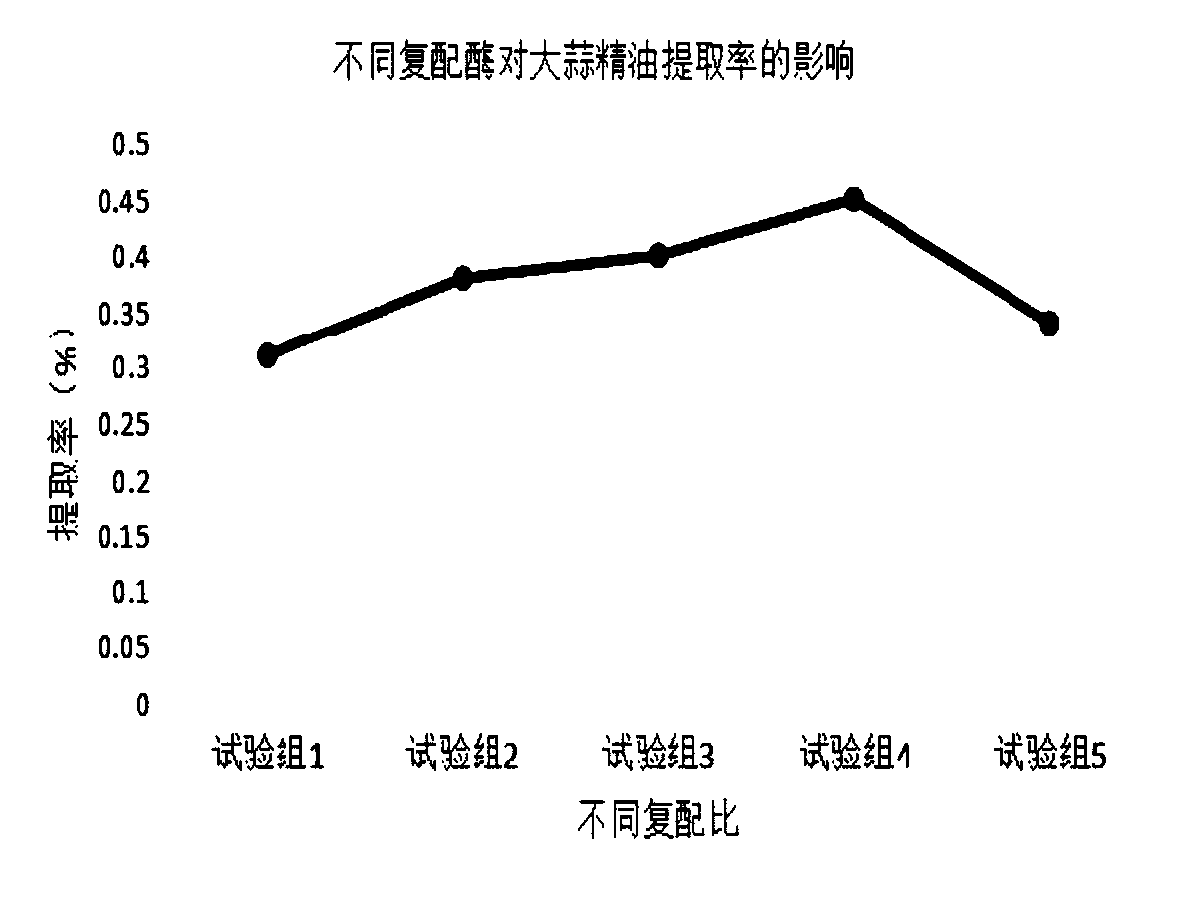

[0033] Get 80g of garlic, wash and beat it, beat it into mashed garlic, add alliinase-cellulose-pectinase 0.48% to the mashed garlic, when the NaCl solvent concentration is 20g / L, the enzymolysis reaction temperature is 37°C, and the enzymolysis time 0.4h, the steam distillation time was 1h, extracted with 1:1 volume ratio of petroleum ether, each group was extracted 3 times, and the average value was taken.

[0034] Test group 1: the ratio of alliinase-cellulase-pectinase: 1:1:1;

[0035] Test group 2: the ratio of alliinase-cellulase-pectinase is: 2:1:2;

[0036] Test group 3: the ratio of alliinase-cellulase-pectinase is: 3:1:3;

[0037] Test group 4: the ratio of alliinase-cellulase-pectinase: 1:2:1;

[0038] Test group 5: the ratio of alliinase-cellulase-pectinase: 1:3:1.

[0039] Calculate the extraction rate of the garlic essential oil of each group respectively, the results are shown in figure 1 . Depend on figure 1 It can be seen that the ratio of alliinase-cell...

Embodiment 2

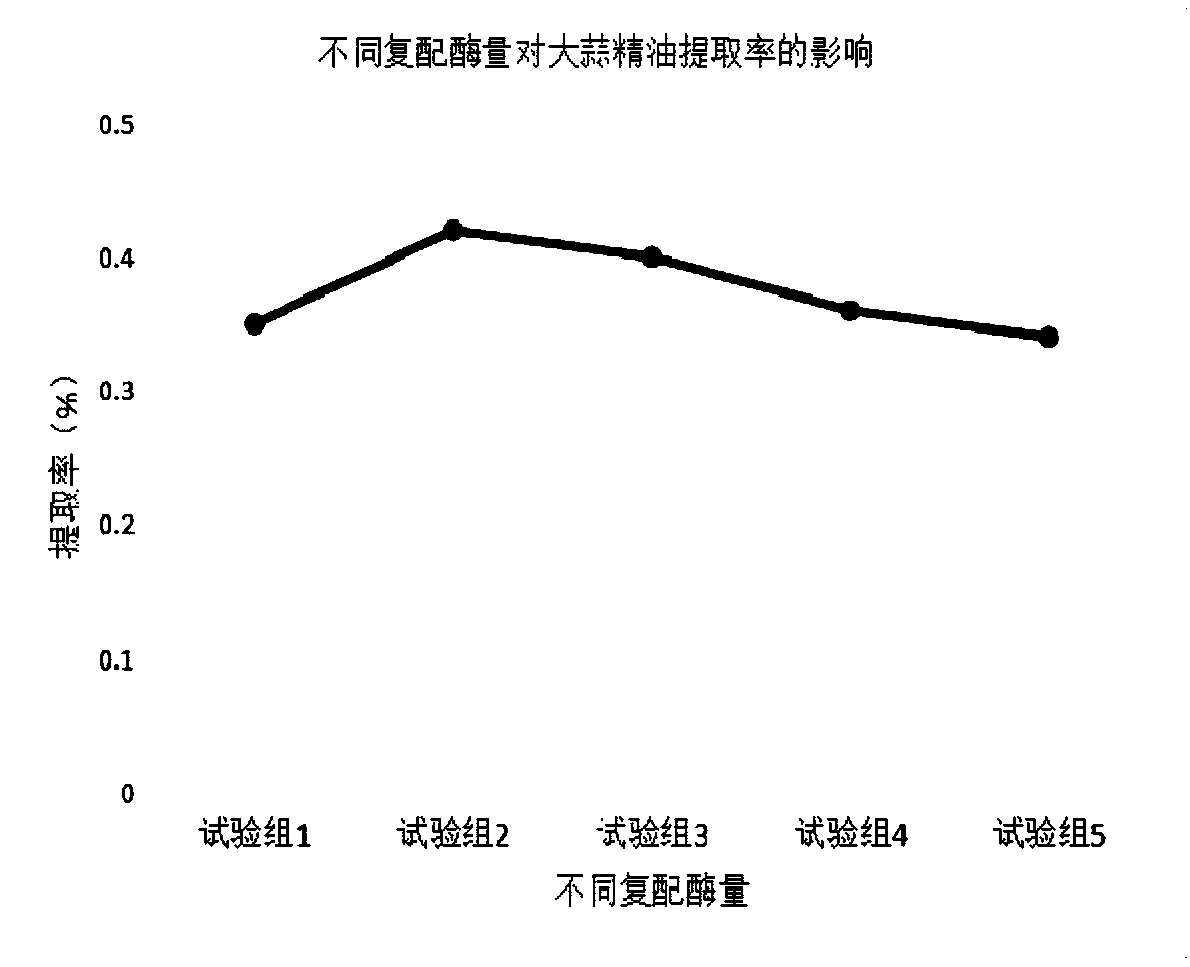

[0041] Get 80g of garlic, wash and beat, beat into mashed garlic, add alliinase-cellulose-pectinase ratio to the mashed garlic to be 3:1:3, when NaCl solvent concentration is 20g / L, enzymolysis reaction temperature is 37 ℃, enzymatic hydrolysis time is 0.8h, steam distillation time is 1.5h, extract with 1:2 volume ratio of petroleum ether, extract 3 times for each group, and take the average value.

[0042] Test group 1: alliinase-cellulase-pectinase quality: 0.36%;

[0043] Test group 2: alliinase-cellulase-pectinase quality: 0.48%;

[0044] Test group 3: alliinase-cellulase-pectinase quality: 0.6%;

[0045] Test group 4: alliinase-cellulase-pectinase quality: 0.72%;

[0046] Test group 5: alliinase-cellulase-pectinase quality: 0.84%;

[0047] Calculate the extraction rate of the garlic essential oil of each group respectively, the results are shown in figure 2 . Depend on figure 2 It can be seen that the extraction rate is the highest when the amount of enzyme added ...

Embodiment 3

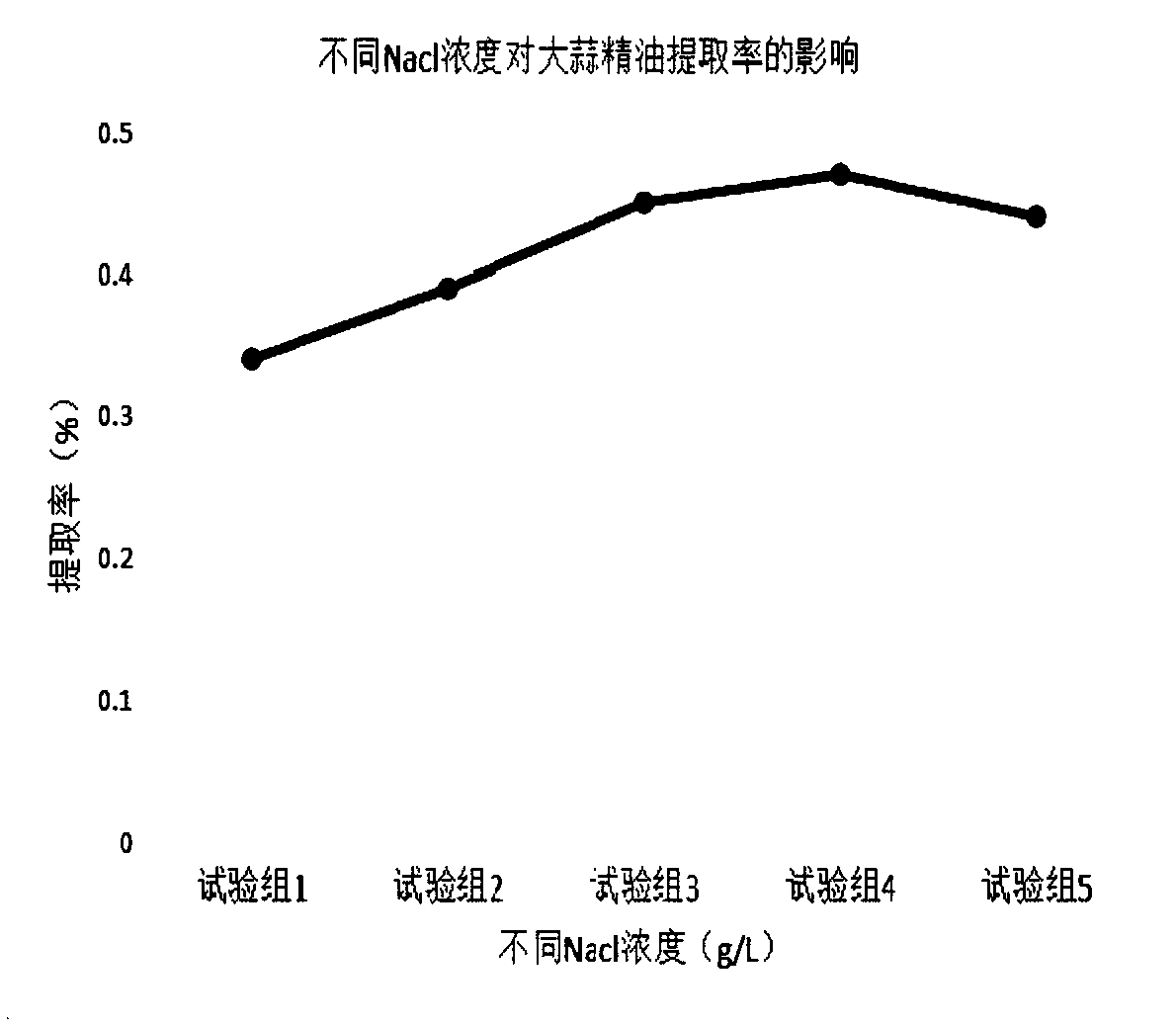

[0049] Take 80g of garlic, wash and beat it, beat it into mashed garlic, add alliinase-cellulose-pectinase in the ratio of 1:2:1 to the mashed garlic, the amount of enzyme added is 0.48%, and the enzymatic hydrolysis reaction temperature is 38°C. The solution time was 0.6h, and the steam distillation time was 1.5h. The essential oil was extracted with petroleum ether at a volume ratio of 1:3. Each group was extracted 3 times, and the average value was taken.

[0050] Test group 1: when the NaCl concentration is 10g / L;

[0051] Test group 2: when the NaCl concentration is 15g / L;

[0052] Test group 3: when the NaCl concentration is 20g / L;

[0053] Test group 4: when the NaCl concentration is 25g / L;

[0054] Test group 5: when the NaCl concentration was 30 g / L.

[0055] Depend on image 3 It can be seen that the extraction rate is the largest when the concentration of NaCl is 25g / L, and slightly decreases when it is 30g / L. The purpose of adding sodium chloride is to increase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com