Use of sliding base and industrial comminution machine

A push plate, industrial technology, applied in the push plate field, can solve the problems of increasing investment and maintenance costs, and achieve the effect of cost saving and device simplification

Inactive Publication Date: 2016-03-02

METSO MINERALS DEUT

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] This device has basically proven effective, but still has certain disadvantages: the loading chute has to have a steep slope to allow the material to pass through the rollers and from there into the shredder

However, this significantly increases investment and maintenance costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0048] The invention is described in more detail below by means of exemplary embodiments.

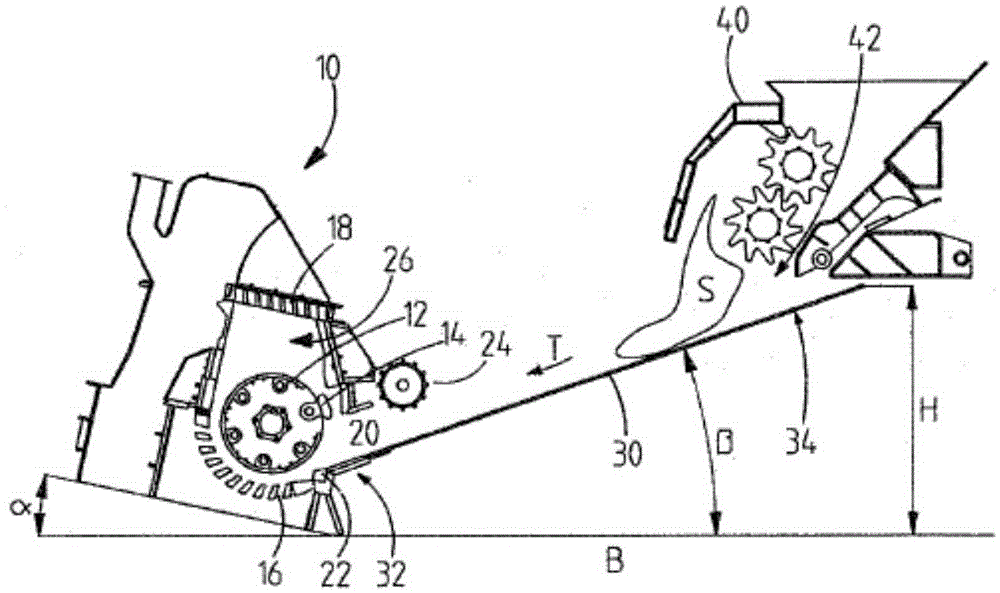

[0049] figure 1 A hammer crusher with an associated push plate is shown in a schematic side view in combination with a pre-shredder.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the use of a sliding base, and to an industrial comminution machine, wherein the sliding base is used.

Description

technical field [0001] The invention relates to the use of a pusher plate of an industrial shredder for filling with waste to be shredded. Background technique [0002] The term "industrial shredder" relates to devices used in the industrial field in order to shred waste. These include, for example, hammer crushers for processing (shredding) car bodies, scrap metal and / or other metallic and / or non-metallic recyclable resources. [0003] A comminution device (shredder device) of this type is described in EP0969932B1. [0004] Materials to be shredded, such as scrap metal or motor vehicle bodies, are relatively inhomogeneous in size and physical properties of the material. [0005] The function of the comminuting device thus depends, inter alia, on how the material is conveyed into the comminuting machine. [0006] From EP0963252B1 it is known that the use material to be shredded is conveyed via a loading chute of a shredding device, above which driven rollers are arranged ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B02C13/286B02C18/22B02C23/02

CPCB02C13/286B02C18/2225B02C2013/28618B02C23/02B02C18/2216

Inventor 奥古斯汀·范德比克埃里希·科尔

Owner METSO MINERALS DEUT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com