Upsetting and elongating device for ring blank prefabricated by hollow steel ingot

A hollow steel, ring-shaped technology, applied in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machines, etc., can solve the problems of axial upsetting of ring-shaped blanks that are not easy, and improve product performance, The effect of improving production efficiency and simplifying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description with reference to the accompanying drawings. It should be understood that the present invention can have various changes in different embodiments without departing from the protection scope of the present invention, and the descriptions and illustrations therein are essentially for illustration rather than for limit the invention.

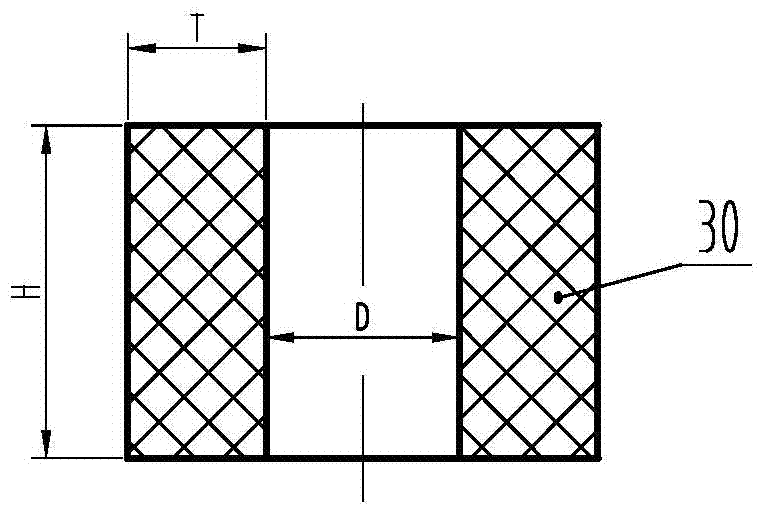

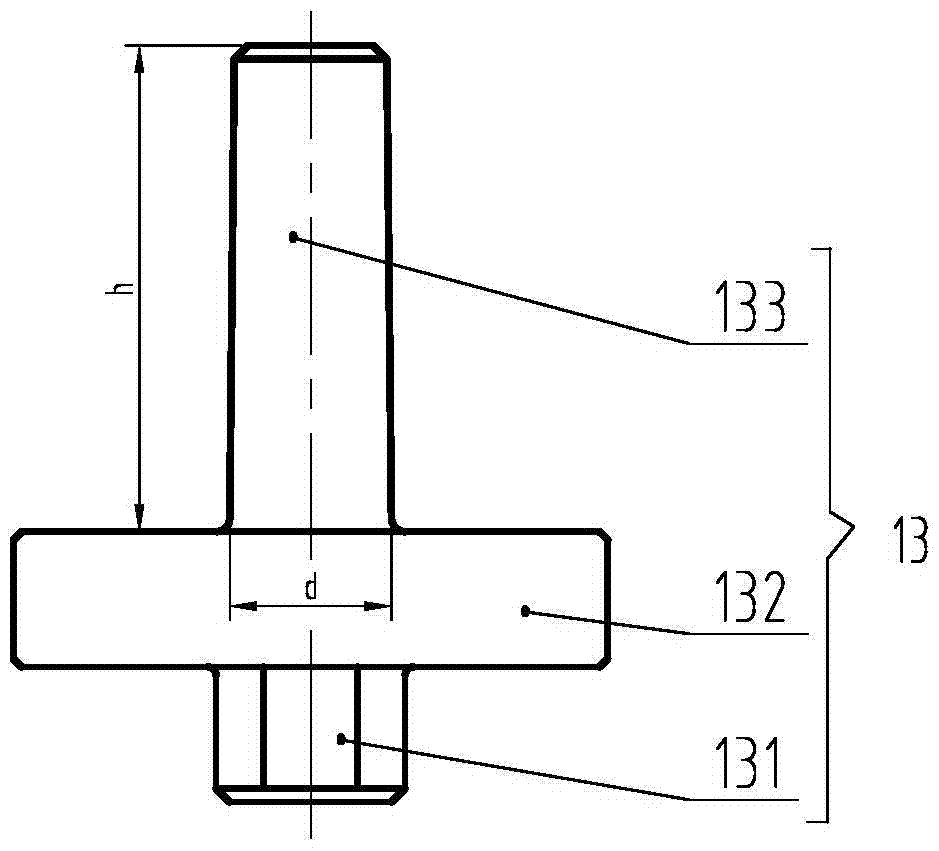

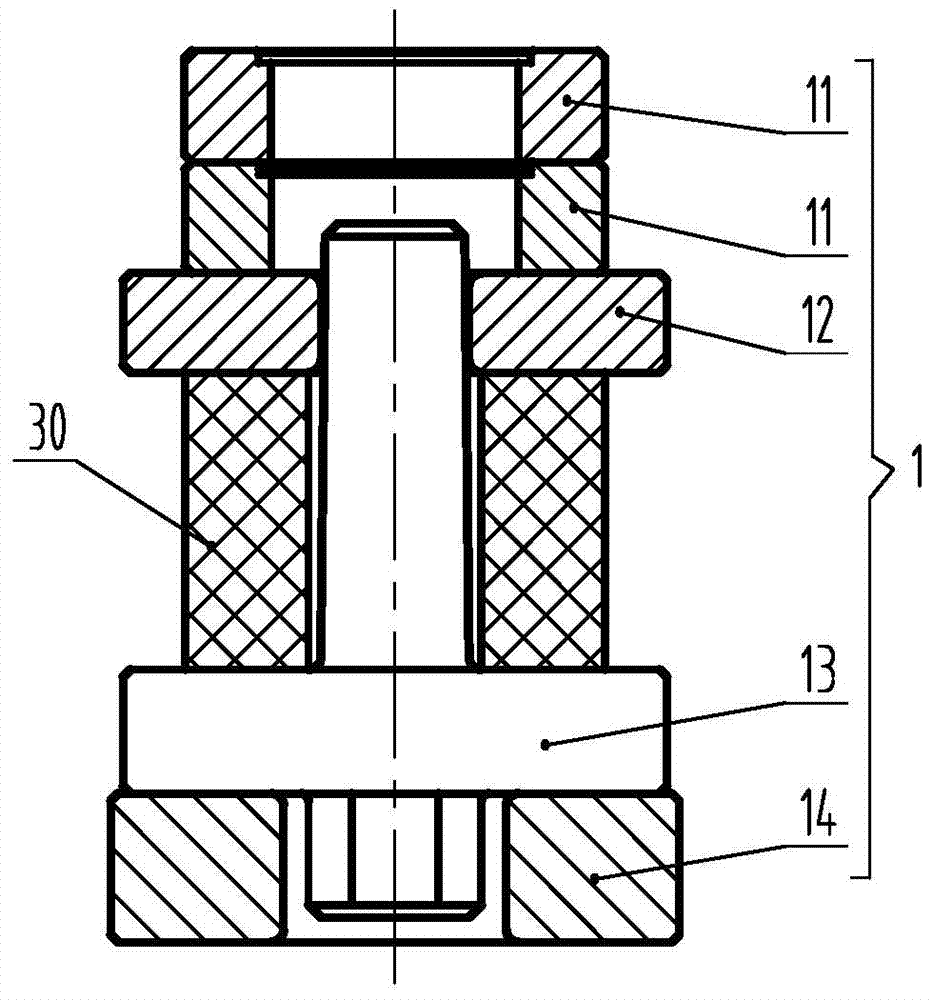

[0016] Such as Figures 1 to 7 As shown, an upsetting and elongating device for prefabricating a ring-shaped blank of a hollow steel ingot is composed of an upsetting device 1 and an elongating device 2 placed on the workbench of a press. The upsetting device 1 consists of a mandrel 13, an upper The backing ring 12, the lower backing ring 14 and N hollow connecting rods 11 are composed, N is a positive integer, and the mandrel 13 is composed of a mandrel chuck 131, a mandrel disk flange 132 and a mandre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com