A Method for Improving the Microstructure Uniformity of Titanium Alloy Large-size Rods

A technology with uniform structure and titanium alloy, which is applied in the field of forging processing of titanium alloy rods, can solve the problems of many times of firing, very high requirements for structure uniformity, and long process, so as to achieve less number of fires, meet quality requirements, and uniform structure good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

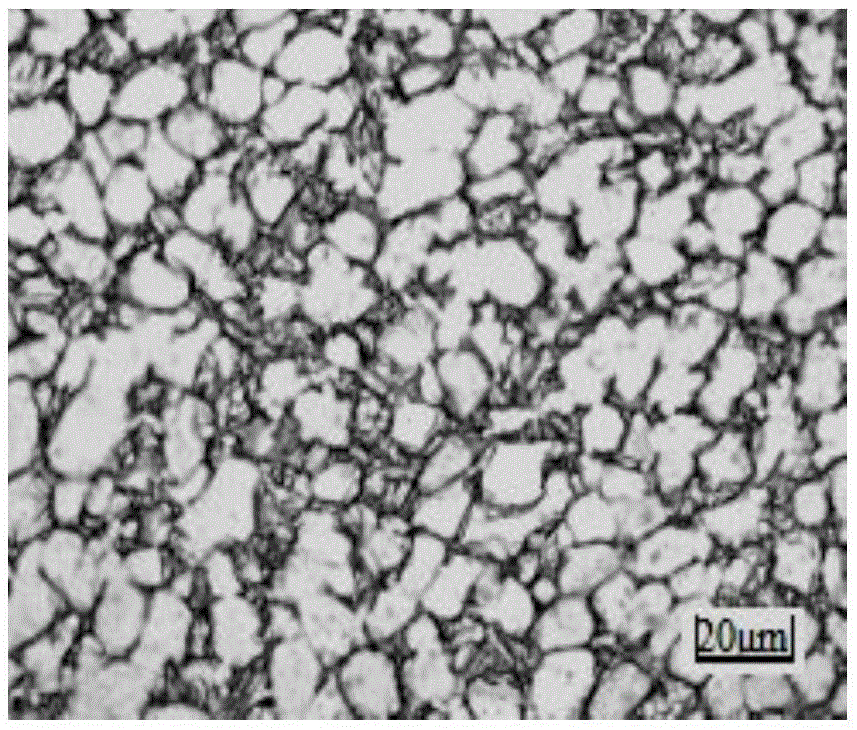

Embodiment 1

[0035] This embodiment is forging a TC4 titanium alloy rod of Φ210×3000mm, and the processing method is as follows:

[0036]Step 1: Heat the TC4 titanium alloy large-size bar at 950°C for heat preservation, and after the heat preservation time is 4 hours, it is out of the furnace for forging;

[0037] Step 2: Use a wide flat anvil for forging, with a reduction of 60mm each time, feed the full anvil, and after forging a stroke (forging from one end to the other end), rotate 180° for flat square forging, and continue feeding the full anvil to forge a stroke , wait until the end of the stroke forging, rotate 90°, continue to send the full anvil to forge another stroke, wait until the end of the stroke forging and then rotate 180°, continue to feed the full anvil to forge a stroke, transition from flat square to square;

[0038] Step 3: After forging the square billet in step 2, carry out reverse forging along the direction of the diagonal line, first use a wide flat anvil, feed i...

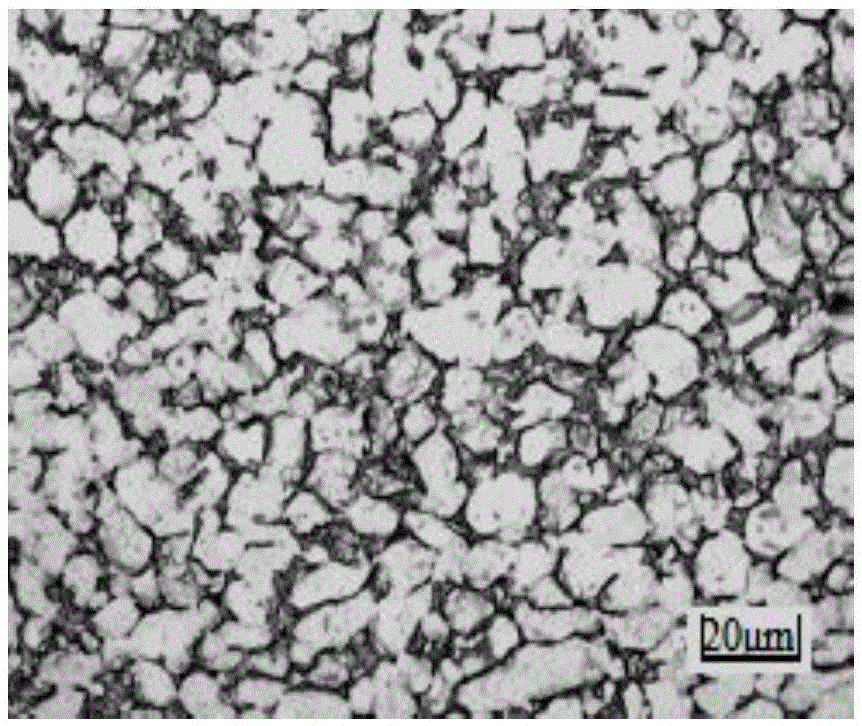

Embodiment 2

[0042] This embodiment is a modified forging of TC4 titanium alloy bar of Φ240×2000mm, and the processing method is as follows:

[0043] Step 1: Heat the C4 titanium alloy large-size bar at 950°C for heat preservation, and after the heat preservation time is 4.5 hours, it is out of the furnace for forging;

[0044] Step 2: Use a wide flat anvil for forging, with a reduction of 70mm each time, feed the full anvil, after forging a stroke (forging from one end to the other end), rotate 180° for flat square forging, continue to feed the full anvil to forge a Stroke, wait until the end of the forging stroke, rotate 90°, continue to send the full anvil to forge another stroke, wait until the end of the stroke forging, then rotate 180°, continue to feed the full anvil to forge a stroke, transition from flat square to square;

[0045] Step 3: After forging the square billet in step 2, carry out reverse forging along the direction of the diagonal line, first use a wide flat anvil, feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com