A kind of forging forming method of hook forging

A forging forming and forging technology, which is applied in the forging field of precisely controlled bending and forming of hook-shaped forgings, can solve the problems of reduced service life, damage to forging fiber streamlines, waste of raw materials, etc., to reduce fire times, improve comprehensive performance, and fiber streamlined full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail by example:

[0030] Forging material: 30CrMnSiNi2A, quantity: 1 piece, blanking specification: Φ120mm×205mm, blanking weight 17.9kg.

[0031] Step 1: Forging billet design

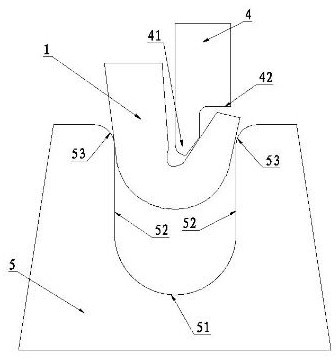

[0032] According to the shape and size of the forging, the total length of the forging blank 1 is designed to be 290mm, the thickness of the forging blank body is 75mm, and the total width is 100mm. The end of the hypotenuse 12 of the forging blank corresponding to the hook part is 50mm wide, the angle of the hypotenuse is 20°, the fillet at the junction between the hypotenuse and the width is set to R50, and the junction between the boss 11 and the body is rounded for R25.

[0033] Step 2: Membrane production

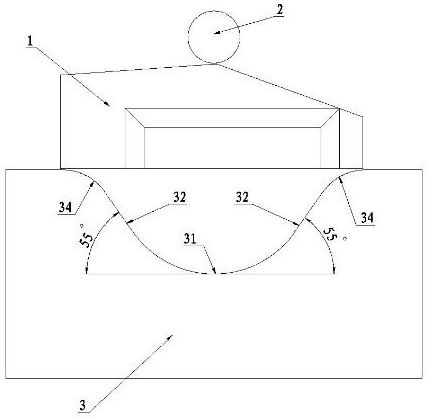

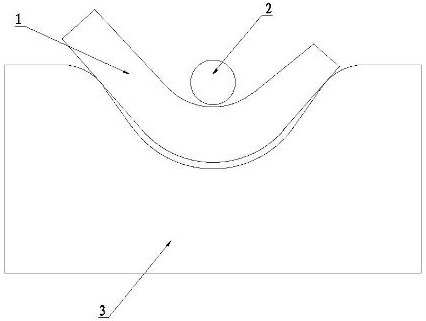

[0034] Membrane 1: The lower membrane 3 is a bending mold with a certain angle, the base is a cuboid, the length is 400mm, the height is 200mm, and the thickness is 100mm. The diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com