Forming method and forming device for large long-axis cross-shaped forging

A cross-shaped and forging technology, which is applied in the field of forming methods and forming devices for large-scale long-axis cross-shaped forgings, can solve the problems of uneven shape, many forging times, difficult to align up and down, symmetrical material distribution, etc. Symmetry, high forging efficiency, and the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is further described below.

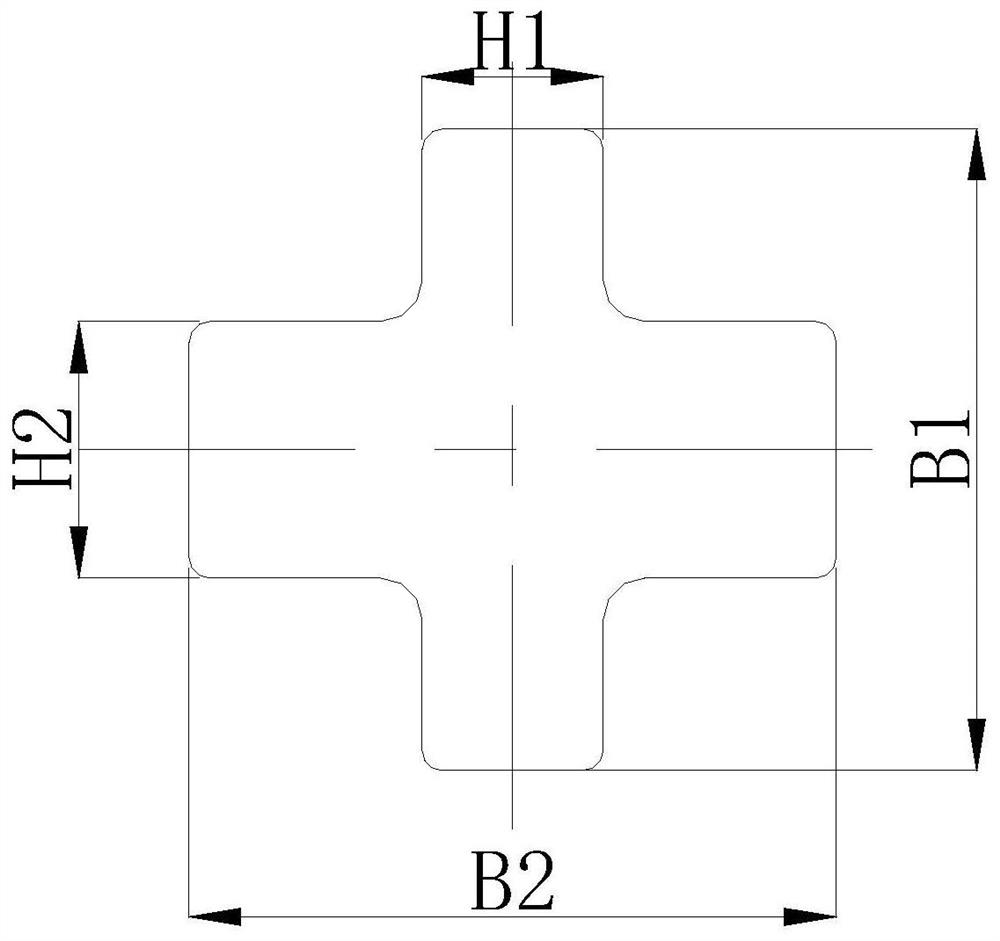

[0045] Such as figure 1 , 2 As shown, it is a typical large-scale long-axis cross-shaped forging. The cross-shaped forging has four protrusions, one pair of protrusions has a thickness of H1, and the other pair of protrusions has a thickness of H2. The cross-section of the cross-shaped forging The vertical and horizontal dimensions are B1 and B2 respectively. The forming method of the large long-axis cross-shaped forging disclosed by the present invention comprises the following steps:

[0046] a. According to the section of the cross forging, prefabricate the blank of the long axis structure;

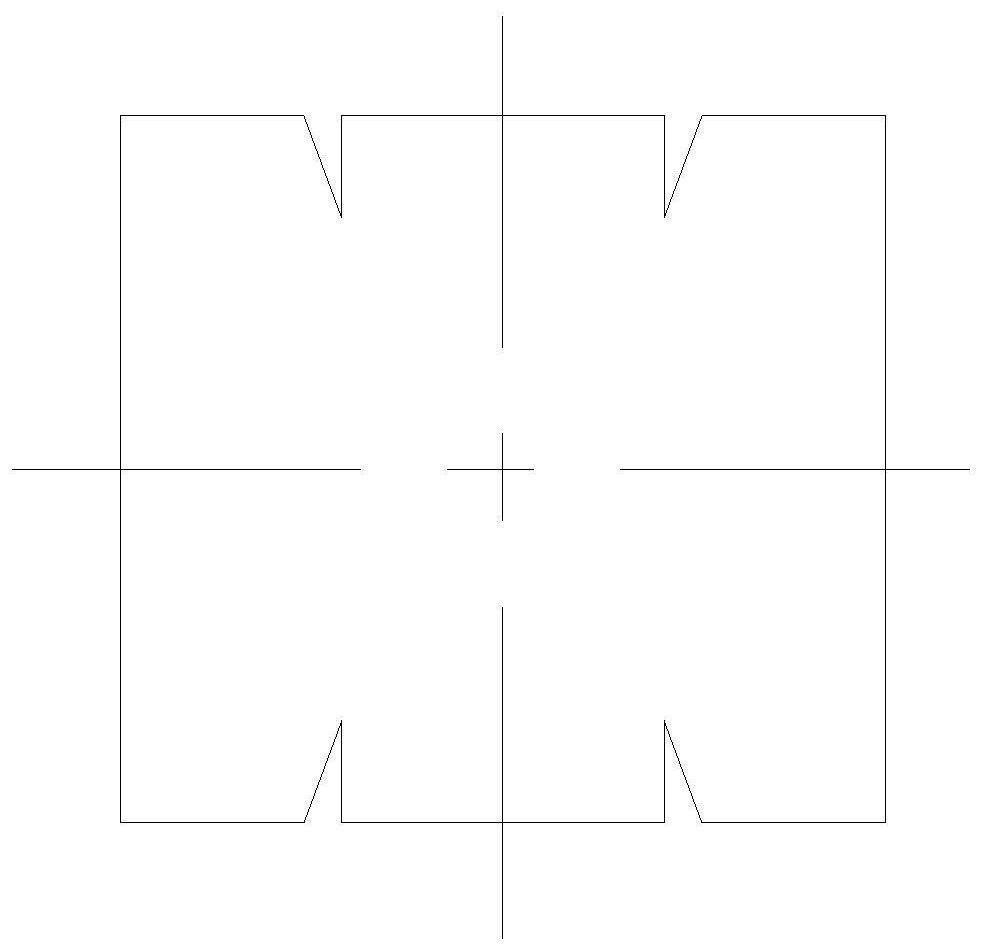

[0047] b. Divide a part of the blank longitudinally on both sides of the central axis of the blank;

[0048] c. Forging the part that has been divided, forming the protrusions on both sides of the cross forging, and actually forming a cross section after forging the protrusions on both sides;

[0049] d. Repeat steps b and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com