Ultrasonic-frequency vibrating combined micro-electrical discharge and electrolysis machining device

A technology of processing device and vibration device, applied in electrochemical processing equipment, metal processing equipment, processing working medium, etc., can solve the problems of difficult to process complex special-shaped surfaces, low efficiency, etc., to improve processing efficiency and accuracy, and solve efficiency. Decreased, increased stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

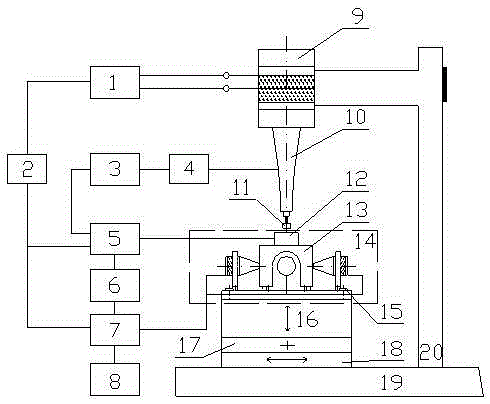

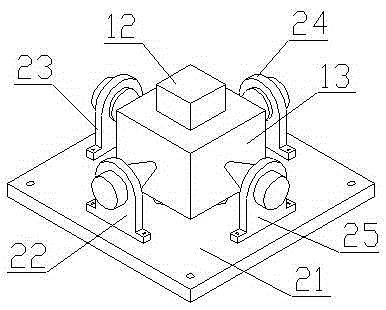

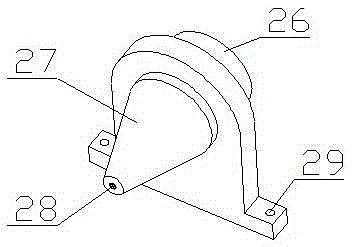

[0027] Such as Figure 1-4 Shown, a kind of supersonic frequency vibration composite micro-discharge and electrolytic processing device, comprises mechanism base 19, the support frame 20 that is arranged on mechanism base 19 and workpiece 12; Composed of a feed mechanism 16, a transverse feed mechanism 18 and a longitudinal feed mechanism 17, the axial feed mechanism 16 is fixed with an ultrasonic vibrating device 14, and the ultrasonic vibrating device 14 is composed of a vibrating device bottom plate 21, a bracket plate, an ultrasonic transducer The workbench 13 is arranged on the bottom plate 21 of the vibrating device, the workpiece 12 is placed above the workbench 13, and the upper end of the support frame 20 is provided with a piezoelectric ultrasonic transducer 9 and an upper horn. 10 and a tool electrode 11; the tool electrode 11 is arranged on the lower end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com