Polishing and feeding device for aluminum panel workpiece and polishing method

A workpiece and trim technology, which is applied in the field of polishing and feeding device and polishing of aluminum trim workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

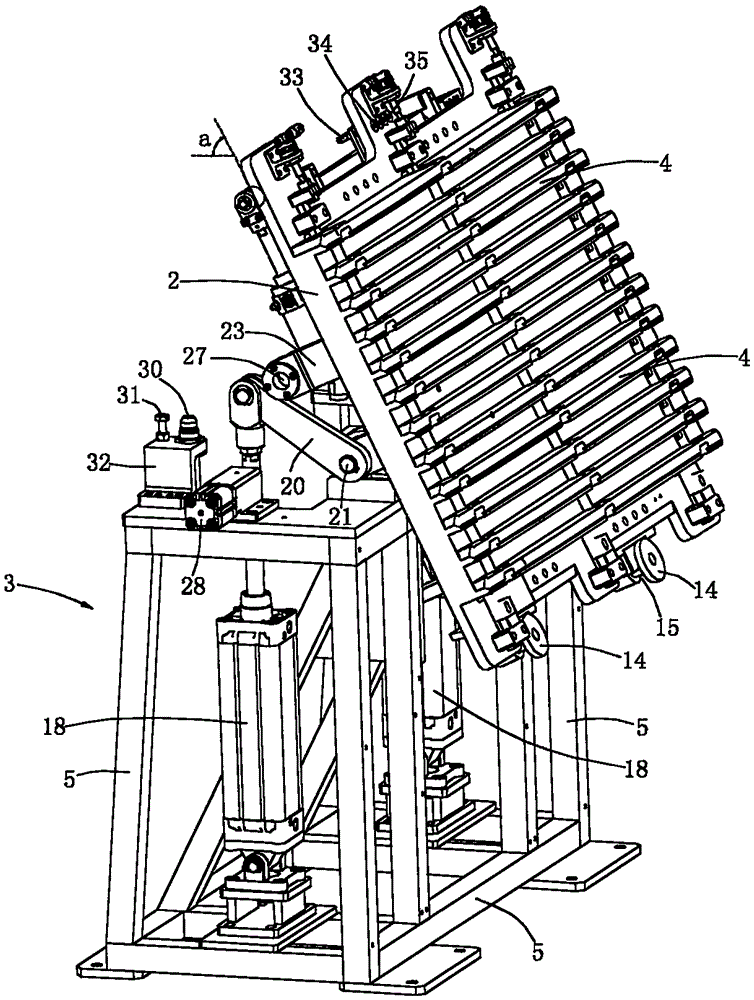

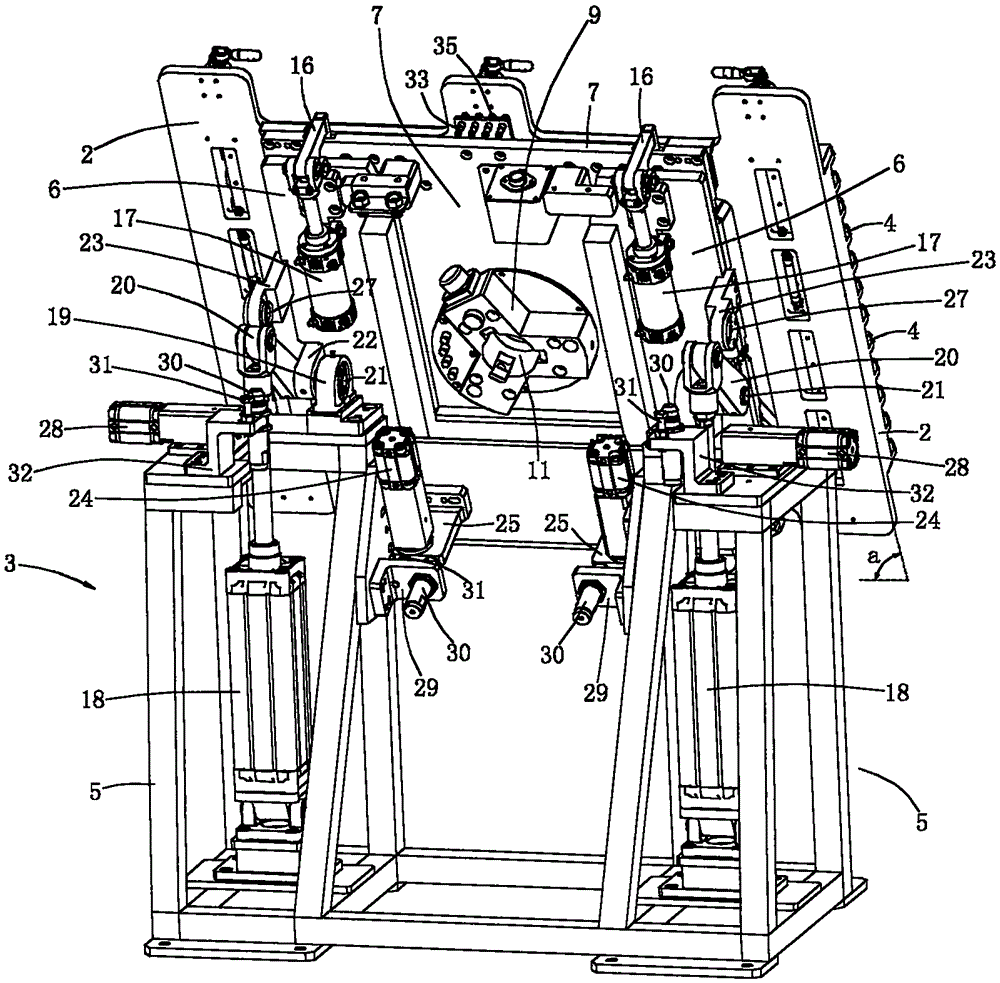

[0031] Such as figure 2 , image 3 As shown, the polishing and feeding device for the aluminum molding workpiece 1 of the present invention is used for the polishing robot to extract the aluminum molding workpiece 1 to be polished and temporarily storing the polished aluminum molding workpiece 1 during the polishing operation of the aluminum molding workpiece 1. A work-holding platen 2 for placing the work piece 1 of aluminum trim and a plate-holding rack 3 for placing the work-holding plate 2 thereon are provided with a plurality of surface shapes, sizes, and the work piece 1 of the aluminum trim The protruding strip 4 with matching shape and size on the back side is provided with a clamping mechanism for clamping the aluminum trim workpiece 1. For example, the applicant in this case filed with the Patent Office of the State Intellectual Property Office on January 6, 2015 and July 08, 2015 Submitted a patent application with the same title of "Aluminum trim workpiece polishing...

Embodiment 2

[0036] The second embodiment is a further improvement for the disadvantage of the inconvenient replacement of the workpiece placing table 2 in the first embodiment. In addition to the polishing and feeding device for the aluminum trim workpiece 1 in the first embodiment, a turning mechanism is added to realize the replacement of the working state and the mold changing state.

[0037] Such as figure 2 , image 3 versus Picture 9 , Picture 10 As shown, the polishing and feeding device of the second embodiment is provided with a turning mechanism to realize the replacement of the working state and the mold changing state. When the mold is changed, the concave plate 6 and the table shelf 7 are in the horizontal position, such as Picture 9 Shown; in the working state, the concave plate 6, the table rest plate 7, and the workpiece rest table 2 are parallel to each other, and all form an inclined angle a with the horizontal plane, such as figure 2 As shown; and set the working state...

Embodiment 3

[0041] In this embodiment, two polishing and feeding devices of the first or second embodiment, a robot, and a polishing machine are used to form a polishing combined device.

[0042] The polishing combination device of this embodiment is such as Picture 12 As shown, a robot 36 is included. The robot 36 has a cantilever 37 that can rotate around its column. In front of the polishing assembly device accessible by the rotating cantilever 37 of the robot 36, two embodiments one or two are arranged side by side. The polishing and feeding device 38 of the robot 36 is provided with a polishing machine 39, or two polishing machines 39 including rough polishing and fine polishing, which include a horizontal polishing machine. The cloth wheel 40 is equipped with at least one spray gun 41 along the polishing cloth wheel 40, and the spray gun 41 is connected to a polishing wax supply source through a conveying pipe.

[0043] Using the above-mentioned polishing combination device, the concav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com