Camera self-calibration method based on two vanishing points

A vanishing point and self-calibration technology, which is applied in image data processing, television, instruments, etc., can solve the problems of complex process and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

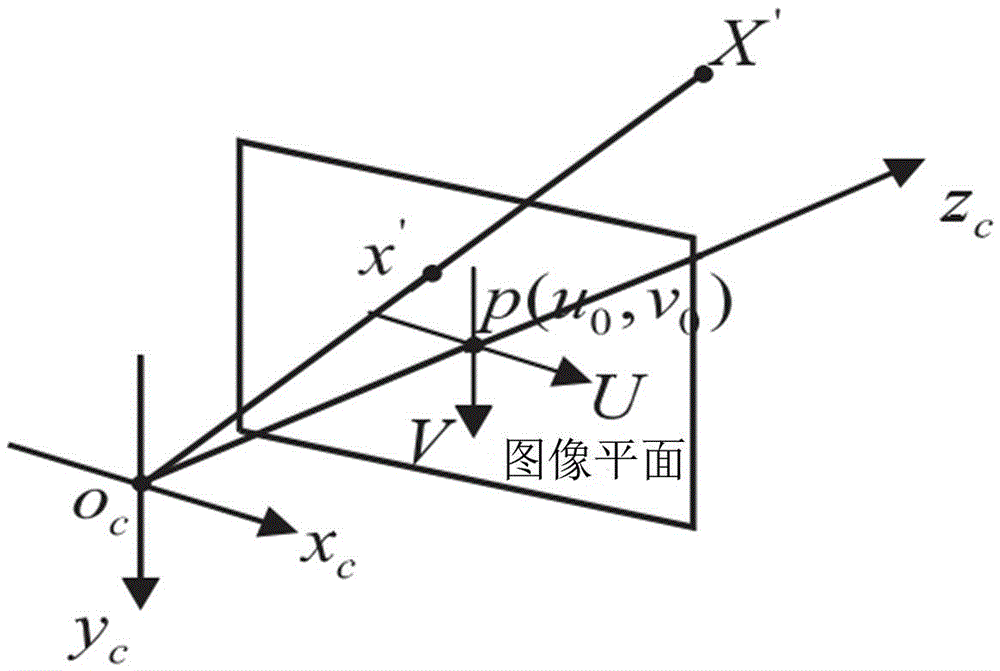

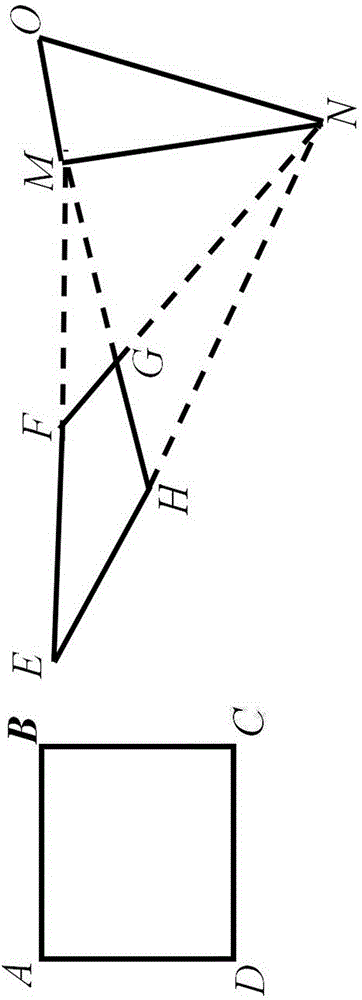

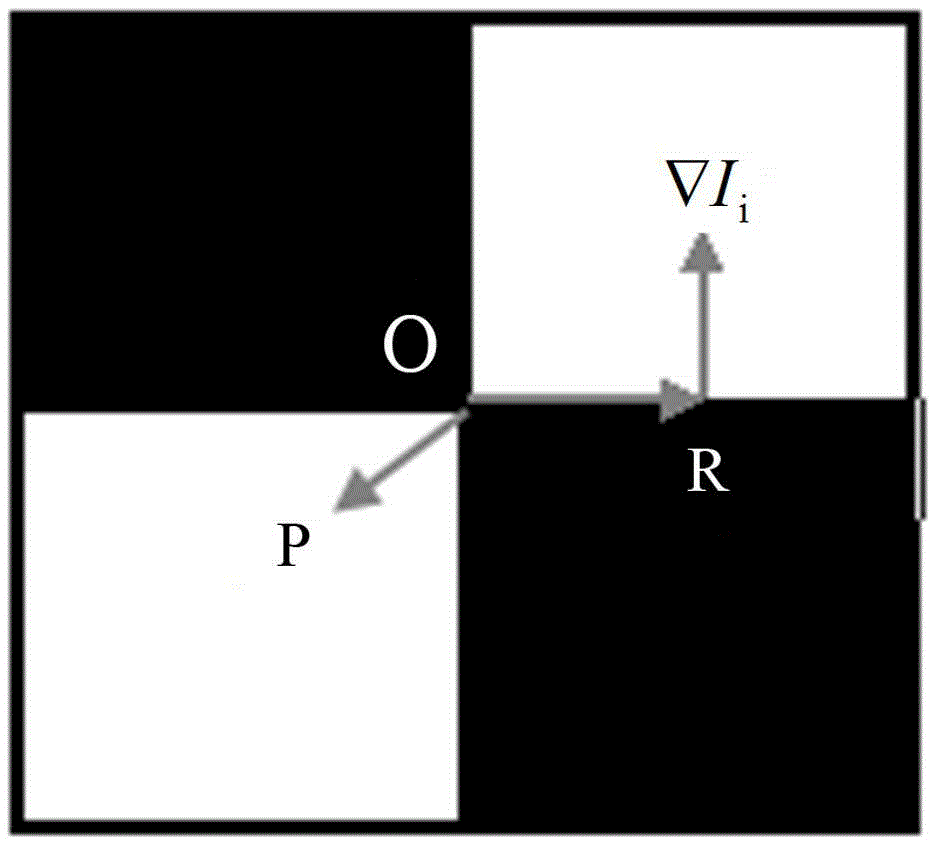

[0040] The present invention provides a camera self-calibration method based on two vanishing points. The so-called two vanishing points refer to two infinity points in the scene where two sets of orthogonal parallel lines intersect in the projective space. The two projection points of are the two vanishing points (see: Caprile, B., Torre, V., "Using Vanishing Points for Camera Calibration," International Journal of Computer Vision. Papers 4(2), 127-140(1990)). According to the projective geometric properties of orthogonal parallel straight lines, it can be known that the optical center and the line connecting the two vanishing points are perpendicular to each other, that is, the optical center is located on a circle whose diameter is the line connecting the two vanishing points, thus establishing the camera internal parameter constrai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com