A supercritical water reactor fuel assembly and core

A supercritical water reactor and fuel assembly technology, applied in the direction of reactor fuel elements, moderator/core structures, reactors, etc., can solve the problem of short core life, uneven power distribution, fuel consumption of theoretical unloading of fuel assemblies Low-level problems, to achieve the effect of prolonging the life of the core, reducing the power peak factor of components, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

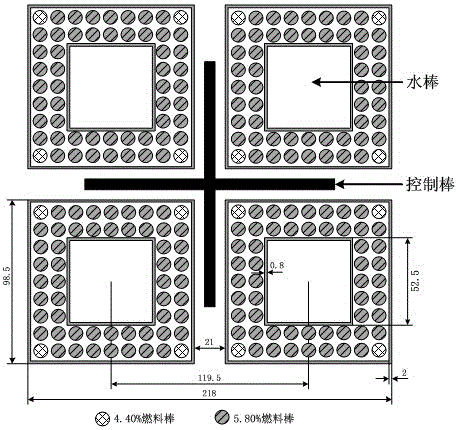

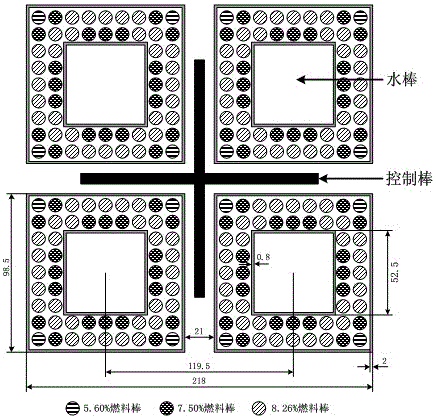

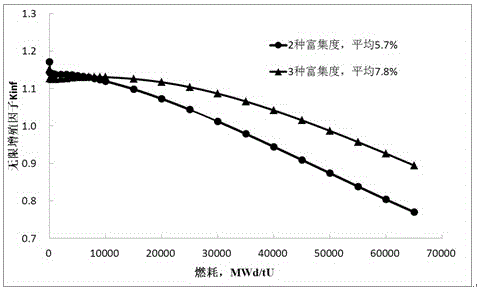

[0033] In the first embodiment, a supercritical water reactor fuel assembly is provided, please refer to Figure 1-Figure 8, a radial 3-zone enrichment arrangement is adopted in the fuel assembly, and the fuel assembly includes:

[0034] Moderator water rods, 4 fuel rods with enrichment of 5.6%, 20 fuel rods with enrichment of 7.5%, and 32 fuel rods with enrichment of 8.26%, wherein the cross section of the fuel assembly is a rectangle In the first rectangle of the cross section of the fuel assembly, there are 56 cell positions evenly distributed in the first rectangle except for the moderator water rod, and each cell position is provided with 1 fuel rod , wherein the four 5.6% enriched fuel rods are respectively distributed at the cell positions of the four corner points of the first rectangle, and the center of the moderator water rod is connected with the first rectangle. The centers overlap, and each fuel rod with 5.6% enrichment is evenly distributed with 2 fuel rods wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com