A pvc pipe manufacturing unit

A PVC pipe and unit technology, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems affecting the manufacturing accuracy of PVC pipe products, PVC pipe bending, power consumption, etc., to achieve simple structure, improve quality, and improve output. Tube Efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

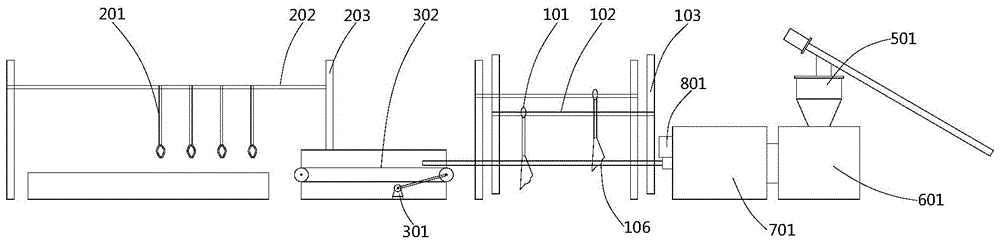

[0046] see figure 1 , the present embodiment provides a PVC pipe manufacturing unit, the PVC pipe manufacturing unit includes a feeding device 501, a heating and melting device 601, a forming system 701, a pipe cutting device 801, and a pipe outlet device connected in series in sequence, the PVC pipe manufacturing unit The extrusion molding system 701 adopted by the pipe outlet device for the production of longer PVC pipes realizes the process of pulling the PVC pipe while forming after extrusion molding.

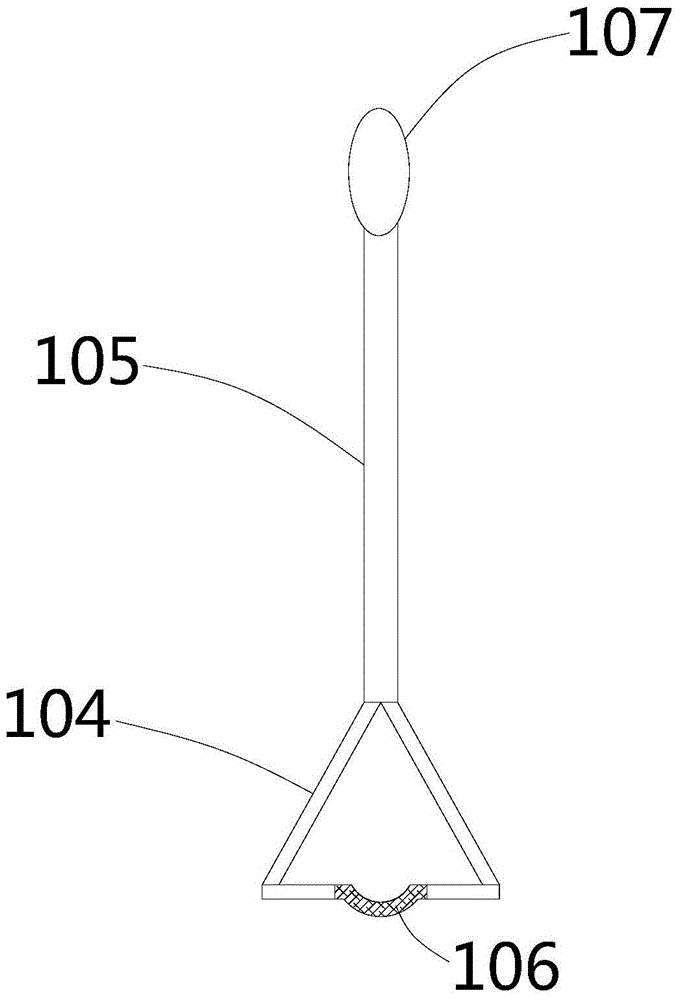

[0047] The pipe outlet device includes at least two hangers 101, a conveying device and several suspension brackets 201, and the upper end of each hanger 101 is respectively slidably connected to a first cable rail 102, and the first cable rail 102 is connected to the first lift. The device 103 is connected, and the conveying device is provided with a conveying rail and a conveying mechanism for driving the PVC pipe to move on the conveying rail. The upper end of the suspe...

no. 2 example

[0065]The basic structure and principle of the PVC pipe manufacturing unit provided by this embodiment and the technical effects produced are the same as those of the first embodiment. For a brief description, the parts not mentioned in this embodiment can refer to the corresponding ones in the first embodiment. content.

[0066] The designer of the present invention found in the research that after the pipes are delivered and placed each time, only one PVC pipe can be placed at a time. Operating costs. In addition, manual counting and tying are required for placement.

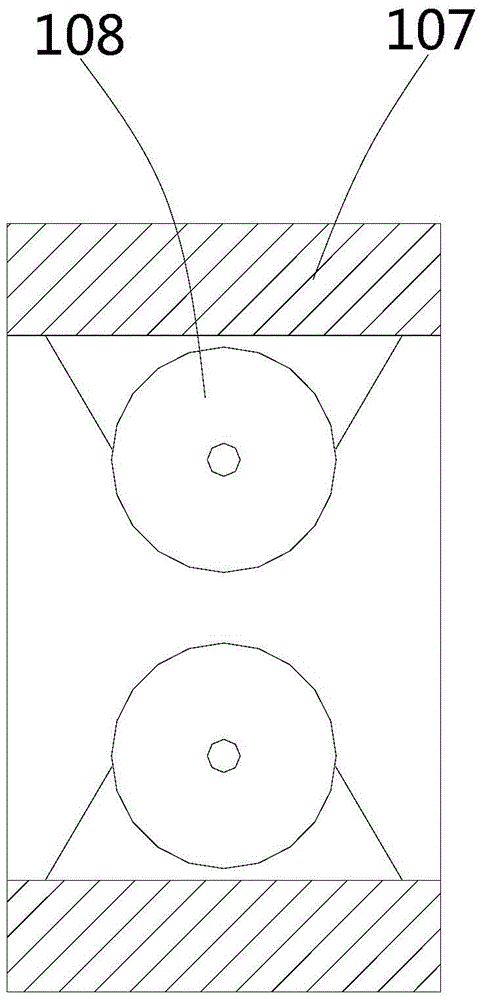

[0067] To resolve this technical issue, please refer to the Figure 8 , in the present embodiment, the conveying device is respectively provided with wheel discs 303 near the two ends of the conveyor belt 302, and a plurality of transfer grooves 304 are evenly arranged on the circumference of the wheel disc 303, and the conveyor belt 302 includes a straight belt 305 and a grooved belt 306. The position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com