False twist processing machine

A processing machine and false twisting technology, applied in textiles and papermaking, etc., can solve the problems of inability to heat and the inability to reach the set temperature, and achieve the effect of reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, preferred embodiments of the present invention will be described.

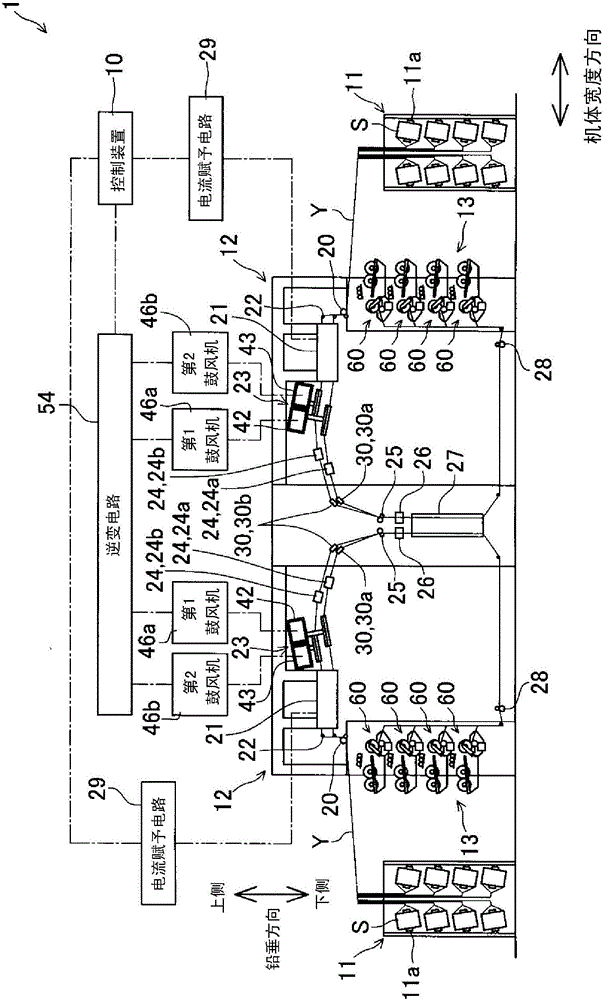

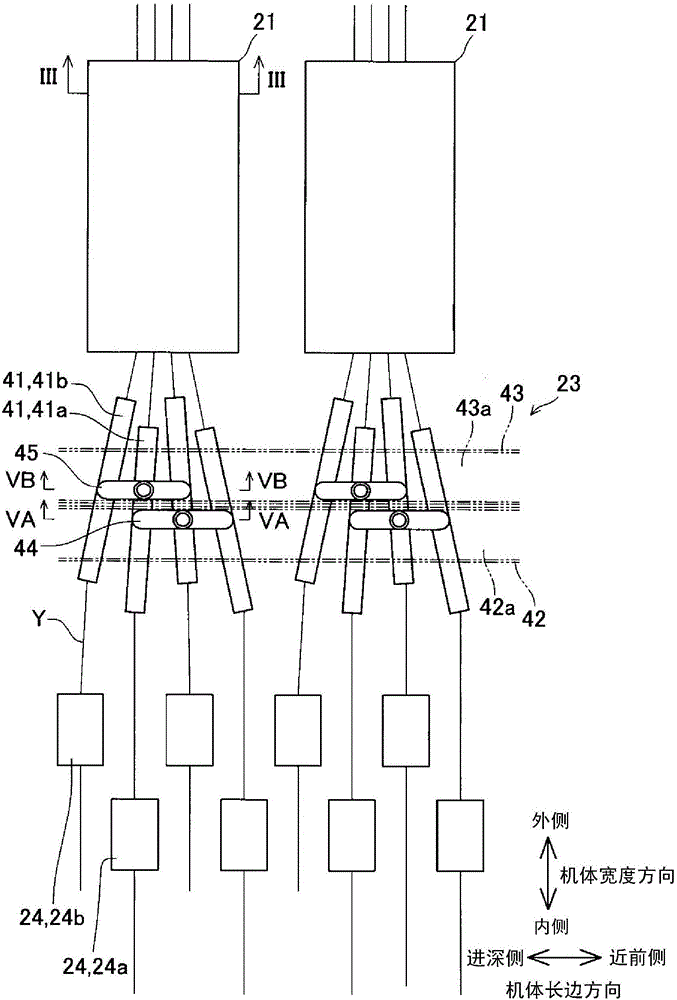

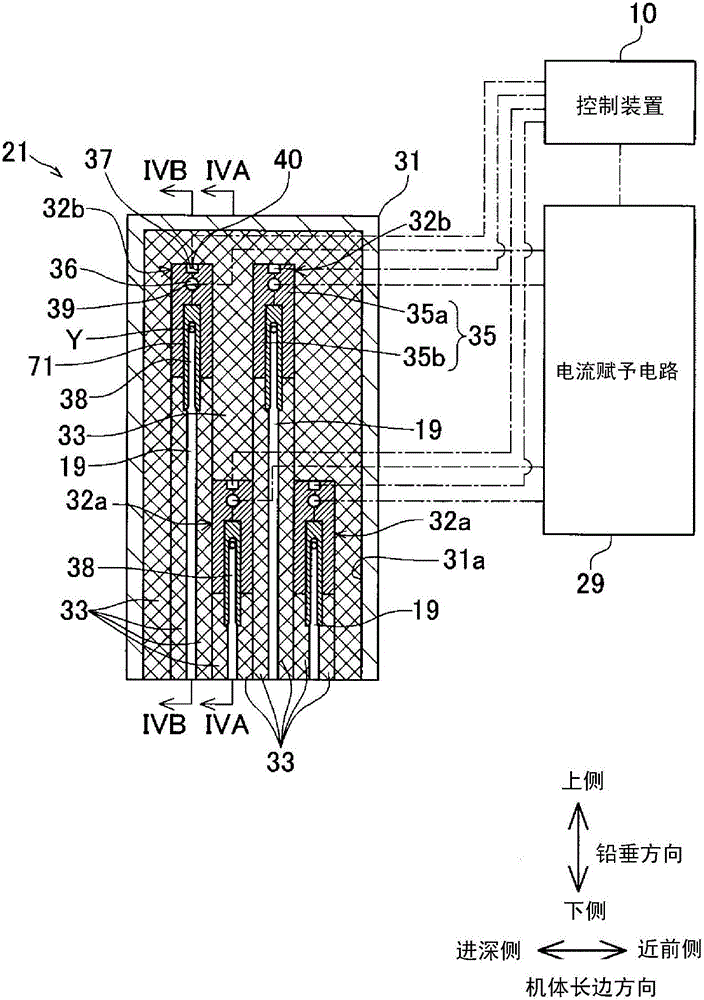

[0049] Such as figure 1 As shown, the false twist processing machine 1 according to this embodiment is each device (the primary yarn feeding roller 20 described later, the primary heating unit 21, the anti-twist yarn guide 22, the cooling device 22, and the Unit 23, twisting device 24, tension sensor 30, secondary yarn feeding roller 25, yarn doubling device 26, secondary heating unit 27, third yarn feeding roller 28, etc.) respectively pass through the yarn processing section 12 from the creel 11 The running surface ( figure 1 paper) orthogonal, horizontal direction of the long side of the body (with figure 1 A plurality of devices that are long in the long side direction of the body are arranged in a direction perpendicular to the paper surface. In addition, in the following, the direction perpendicular to and horizontal to the long side of the body ( figure 1 The left and right direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com