Anti-warp floor easy to lay and manufacturing method thereof

A kind of floor and simple technology, applied in the direction of building structure, floor, building, etc., can solve the problems of noise impact, affect the appearance, difficult to repair, etc., to reduce footsteps and improve connection stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

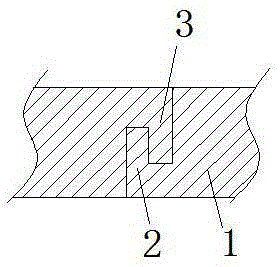

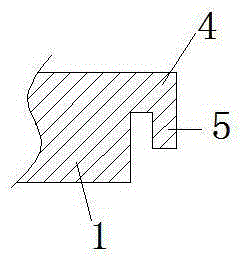

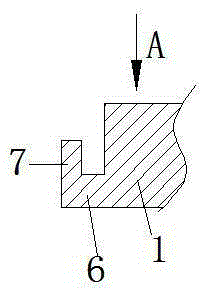

[0036] It can be seen from the accompanying drawings that this kind of simple laying anti-warping floor includes a floor body 1. The floor body 1 is in the shape of a rectangular flat plate. One side of the floor body 1 is provided with several upper snap-fit buckles 3. There are several lower snap-in buckles 2 arranged on the side, and there is a space between any adjacent said upper snap-in buckles 3, which is greater than the width of the lower snap-in buckles 2, and any adjacent said lower snap-in buckles 2 There is a space between them, which is greater than the width of the upper snap-fit buckle 3. During the installation process of the present invention, the lower snap-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com