Single-cylinder reciprocating piston type compressor

A technology of reciprocating pistons and compressors, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc. It can solve the problems of discontinuous suction and exhaust, improve the efficiency of suction and exhaust, and achieve continuity , to reduce the effect of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

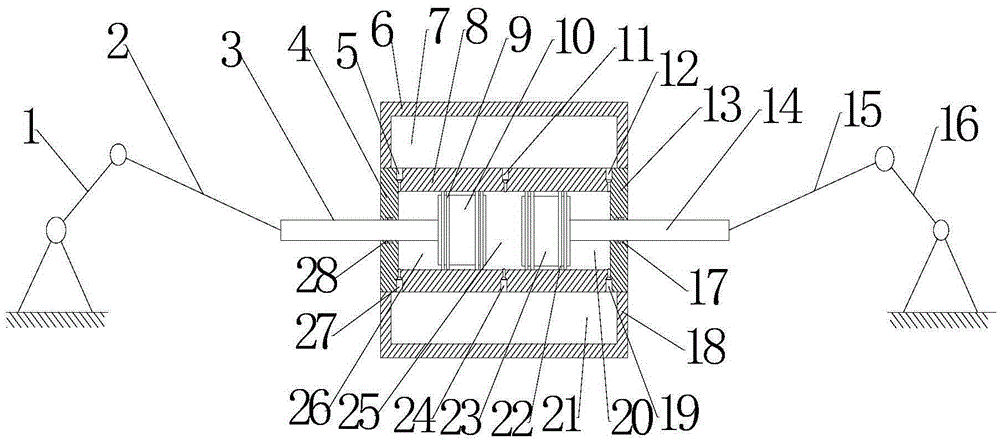

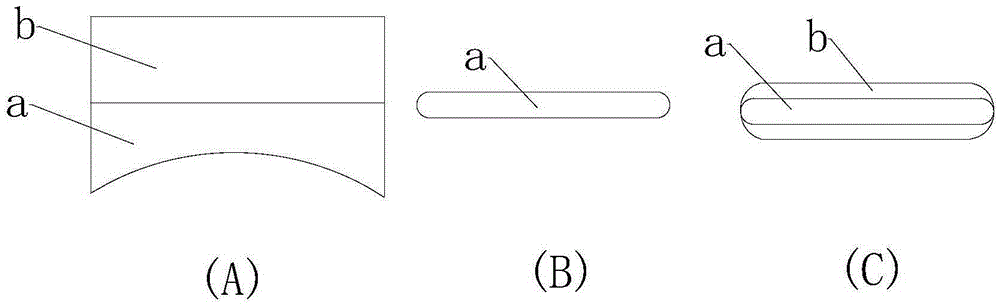

[0023] Such as figure 1 As shown, the present invention provides a single-cylinder reciprocating piston compressor, which includes a cylinder and two pistons arranged inside the cylinder, the two pistons divide the cylinder into three compression chambers, and the two pistons The three compression chambers are driven to and fro independently by being driven by the respective power mechanisms, and the three compression chambers are provided with suction ports on the same side of the cylinder and exhaust ports on the other side, and at least two The compression chambers are not simultaneously sucked in and / or exhausted.

[0024] The structure of three compression chambers formed by the two pistons of the single-cylinder reciprocating piston compressor of the present invention, and the three compression chambers are all provided with suction ports on the same side of the cylinder, and exhaust ports are provided on the other side, and combined with at least The structure of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com