Exhaust valve assembly of refrigerator compressor

A refrigerator compressor and exhaust valve technology, applied in pump components, mechanical equipment, variable capacity pump components, etc., can solve the problems of affecting refrigeration effect, reducing refrigeration efficiency, refrigerant leakage, etc., achieving novel structure and improving suction. Exhaust Efficiency and Area Enlargement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

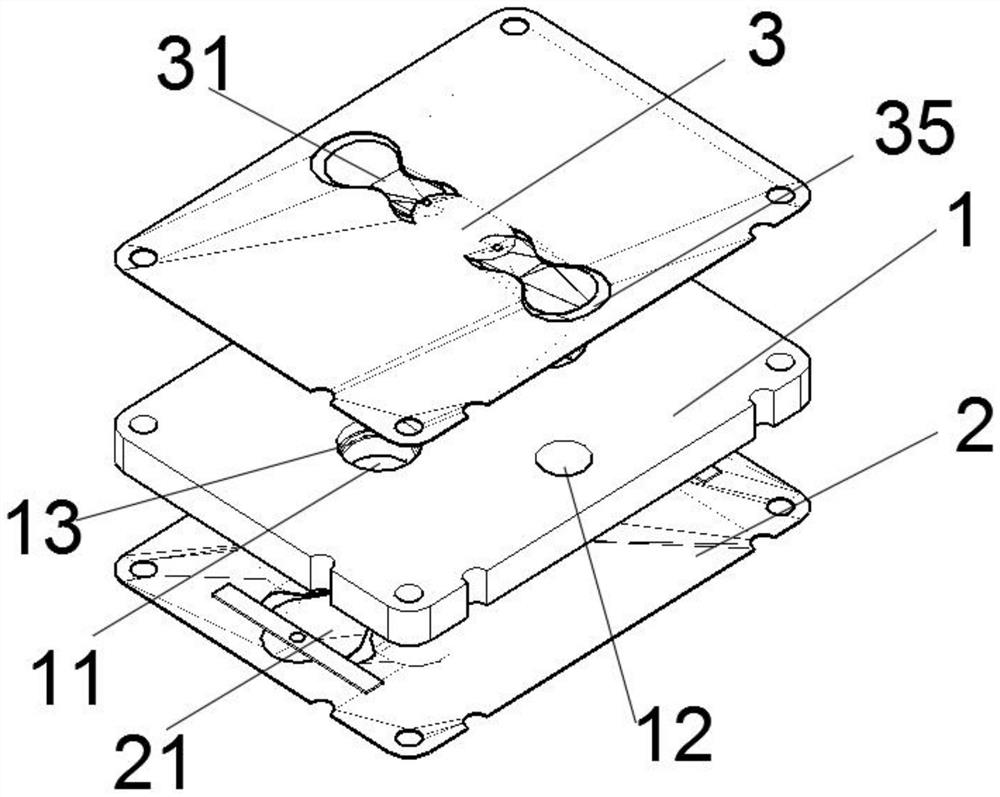

[0028] Specific embodiment 1, referring to the accompanying drawings of the description, a refrigerator compressor exhaust valve assembly, including:

[0029] Valve plate 1, the valve plate 1 is provided with a suction port 11 and an exhaust port 12, and the inner ring of the suction port 11 is connected with a buffer sleeve 13;

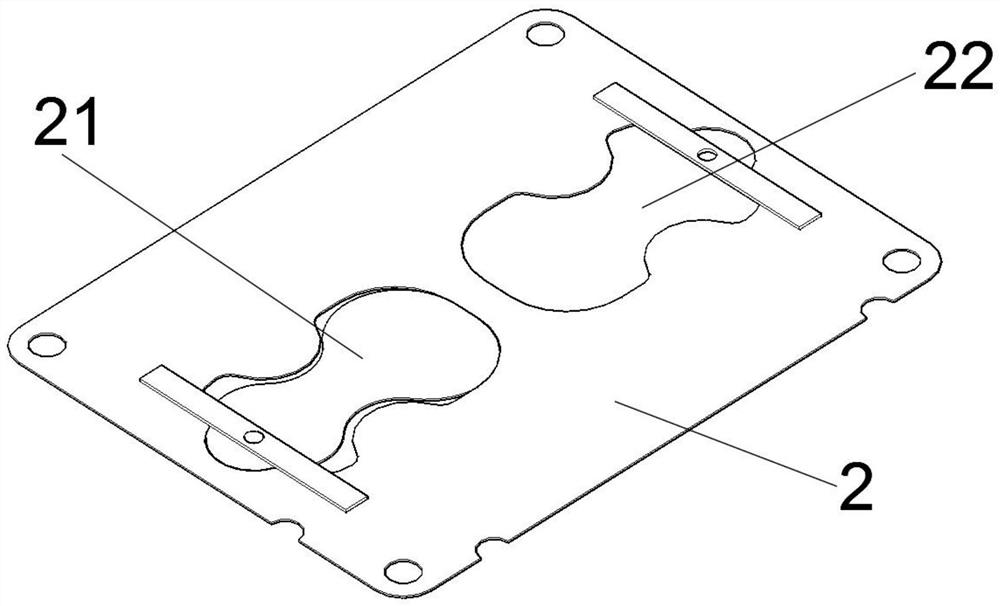

[0030] The suction valve piece 2, the suction valve piece 2 is arranged on the lower surface of the valve plate 1, and the suction valve piece 2 is connected with a suction reed 21 corresponding to the suction port 11;

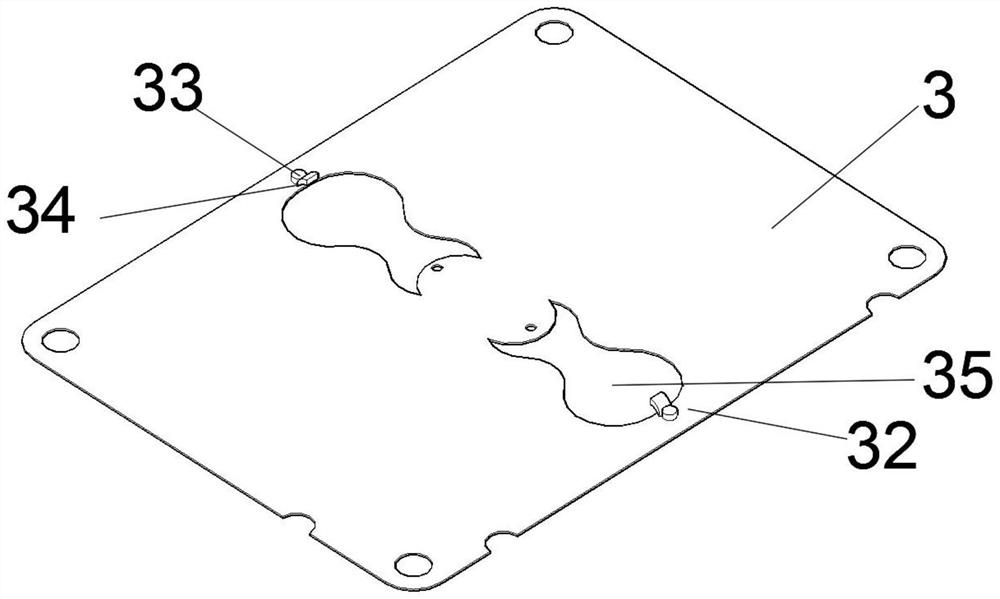

[0031] Exhaust valve sheet 3, the exhaust valve sheet 3 is located on the upper surface of the valve plate 1 corresponding to the suction valve sheet 2, and the exhaust valve sheet 3 is connected with a valve corresponding to the exhaust port 12. The exhaust reed 31.

[0032] Further, the buffer sleeve 13 includes an outer ring sleeve 131 threadedly connected with the suction port, the inner thread of the outer ring sleeve 131 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com