Connection movement support shaft structure

A technology of movable support and support shaft, applied in the direction of connecting rod, shaft and bearing, mechanical equipment, etc., can solve the problems of low service life, support shaft wear, lack of flexibility, etc., to increase service life, slow down external force, reduce wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

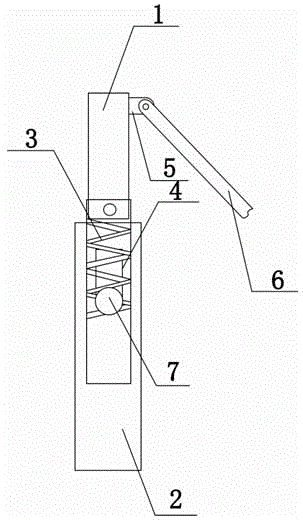

[0010] see figure 1 , connected to the movable support shaft structure, including the support shaft 1 and the shaft tube 2 connected to the bottom of the support shaft 1, a pin hole 4 is opened on the shaft tube 2, the pin hole 4 is rectangular, and a pin hole 4 is provided in the pin hole 4 pin, and the diameter of the pin cap 7 is longer than the width of the pin hole 4, and also includes a gasket, one end of the support shaft 1 is connected to one end of the gasket, the other end of the gasket is fixed on the shaft tube 2, and the gasket is also provided with a The force valve 3 and the force reducing valve 3 are arranged between the support shaft 1 and the shaft tube 2. One end of the force reducing valve 3 is connected to the bottom of the support shaft 1, and the pin cap 7 is engaged with the force reducing valve 3. During mechanical movement, the force reducing valve 3 The force valve 3 plays a role in slowing down the external force, and the force reducing valve 3 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com