Packaging device of fiber bragg grating temperature sensor

A temperature sensor, fiber grating technology, applied in thermometers, measuring devices, thermometers with physical/chemical changes, etc., can solve the problems of small temperature measurement range, insufficient temperature sensor sensitivity, etc., to achieve high sensitivity, wide temperature measurement range, The effect of increasing the amount of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below based on specific embodiments and in conjunction with the accompanying drawings.

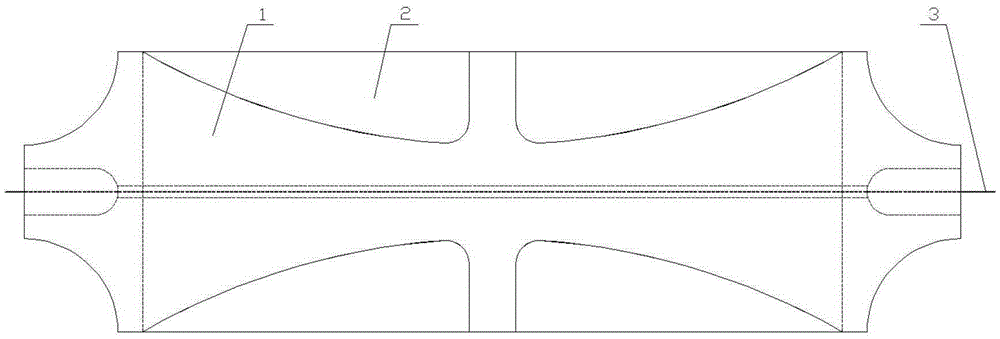

[0015] refer to figure 1 As shown, the packaging device of the fiber grating temperature sensor according to the present invention includes a base body 1, a base body shell 2 and a fiber grating 3, the fiber grating 3 is pasted to the axial center of the base body 1, and the base body shell 2 is connected to the base body 1 with an interference fit .

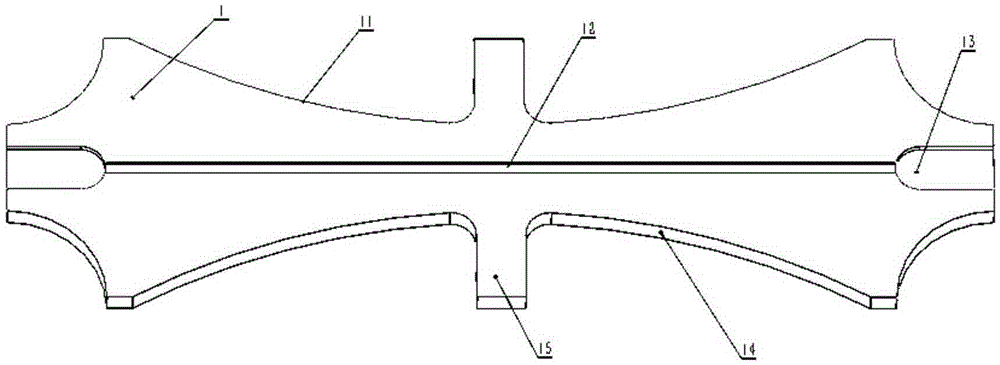

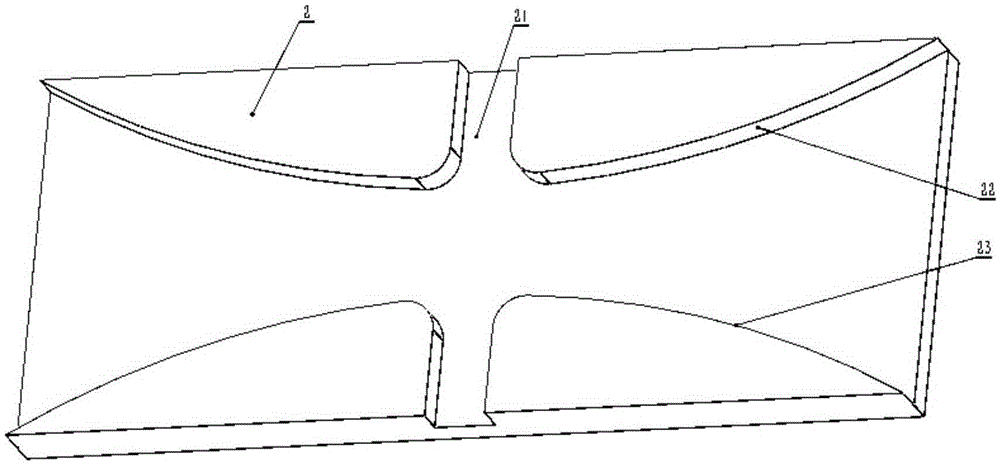

[0016] refer to figure 2 As shown, the base 1 is provided with a central groove 12 along its axial center, the two ends of the central groove 12 are respectively provided with fiber grating bonding grooves 13, and the base 1 is symmetrically provided with first hyperboloids 11 on both sides of the central groove 12. and the second hyperboloid 14, and the centers of the first hyperboloid 11 and the second hyperboloid 14 are respectively provided with a substrate bonding surfa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap