Constant Force Mechanism, Movement And Timepiece

A movement and power source technology, applied to clocks, clock drive mechanisms, mechanically driven clocks, etc., can solve problems such as inability to ensure deflection, reduced timing accuracy, and large changes in deflection and torque, and achieve good results. Timing accuracy, ensuring timing accuracy, and the effect of stable driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

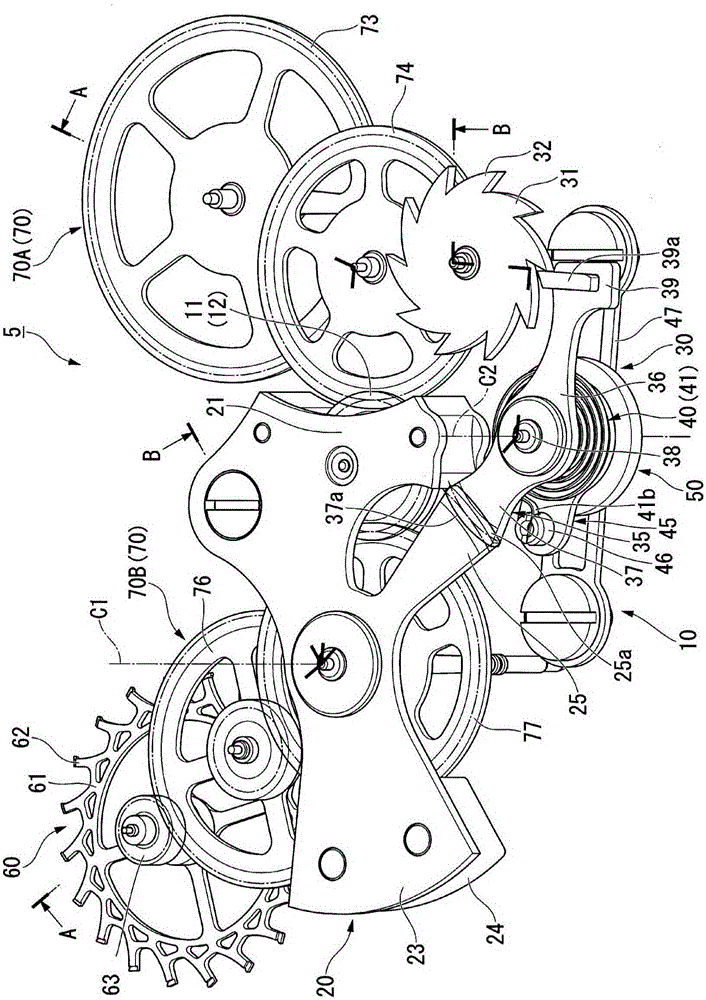

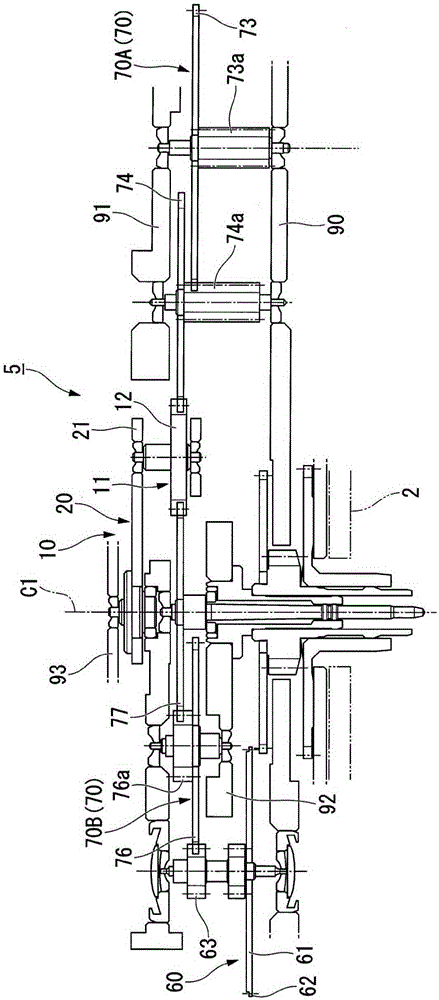

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0033] Generally, the mechanical body including the driving part of the timepiece is called the "movement". The state in which the dial and the hands are mounted on the movement and put into the watch case to become a finished product is called the "complete" of the watch. Among the two sides of the bottom plate of the substrate constituting the timepiece, the side where the glass of the timepiece case is present, that is, the side where the dial is present is referred to as the "back side" of the movement. In addition, among the two sides of the bottom plate, the side where the case back cover of the watch case exists, that is, the side opposite to the dial is referred to as the "front side" of the movement.

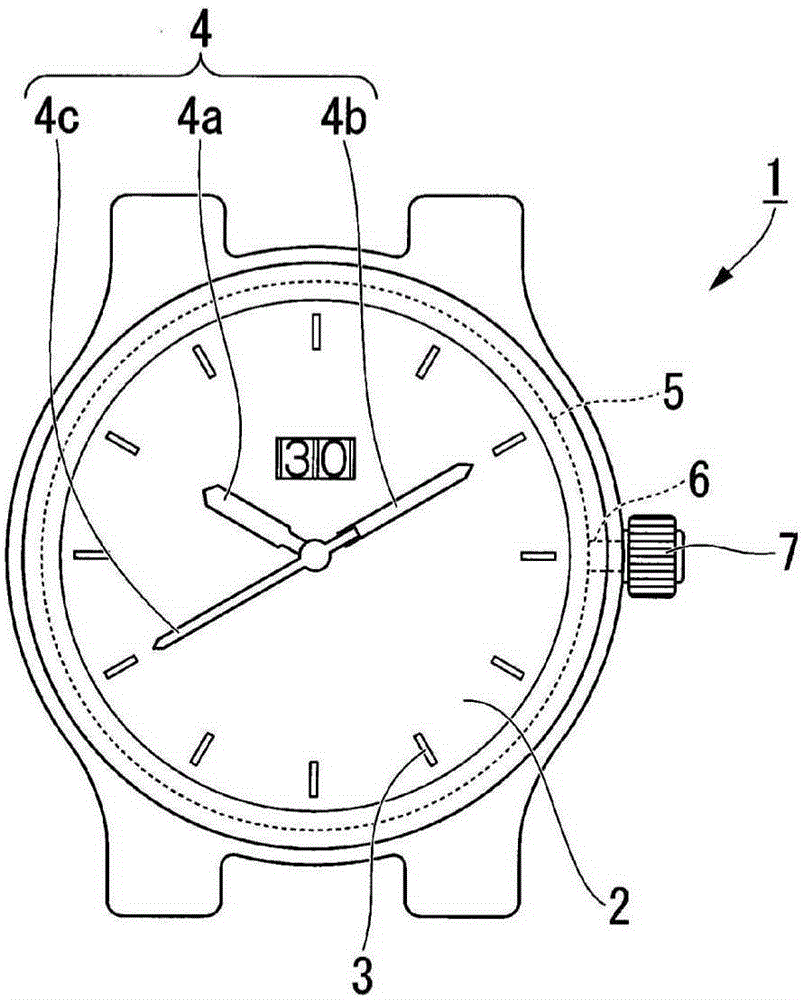

[0034] figure 1 It is a top view of the clock 1.

[0035] Such as figure 1 As shown, the timepiece 1 includes a dial 2 including a scale 3 and the like, and the scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com