Filter Insert

A filter device and filter element technology, which is applied in the direction of membrane filter, dispersed particle filter, mechanical equipment, etc., to achieve the effect of easy flow away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

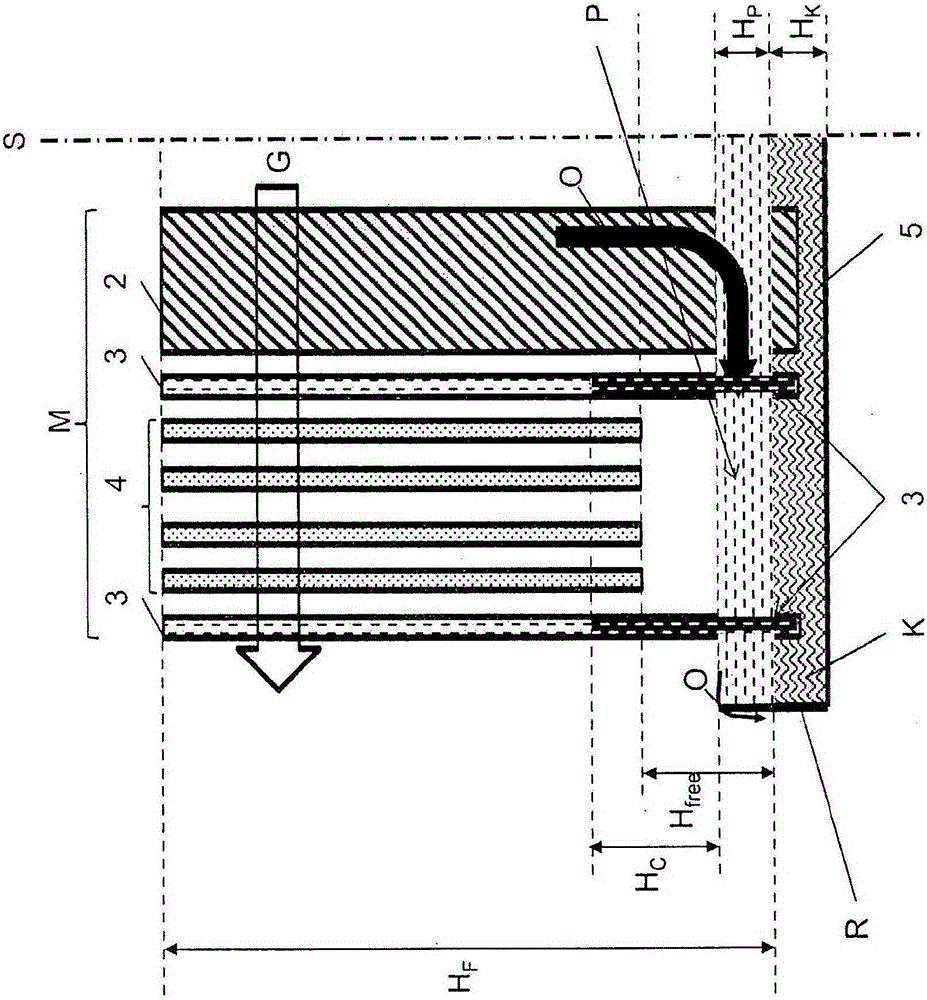

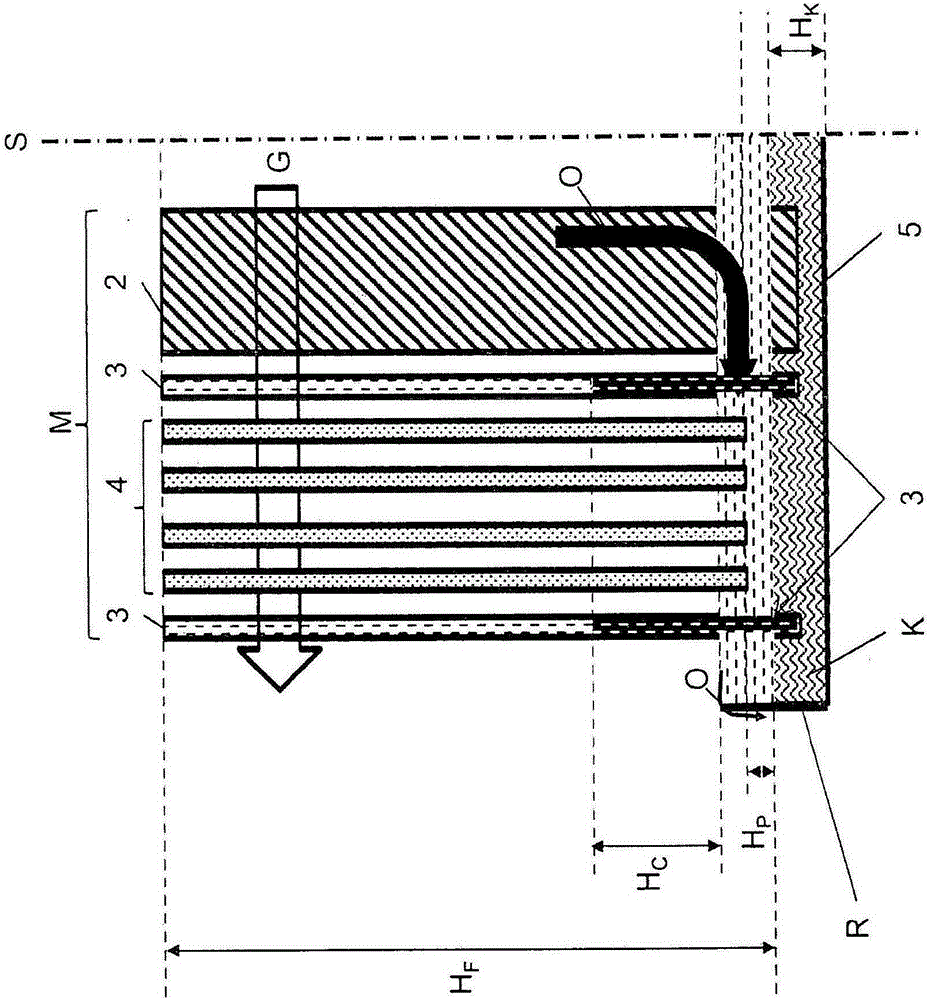

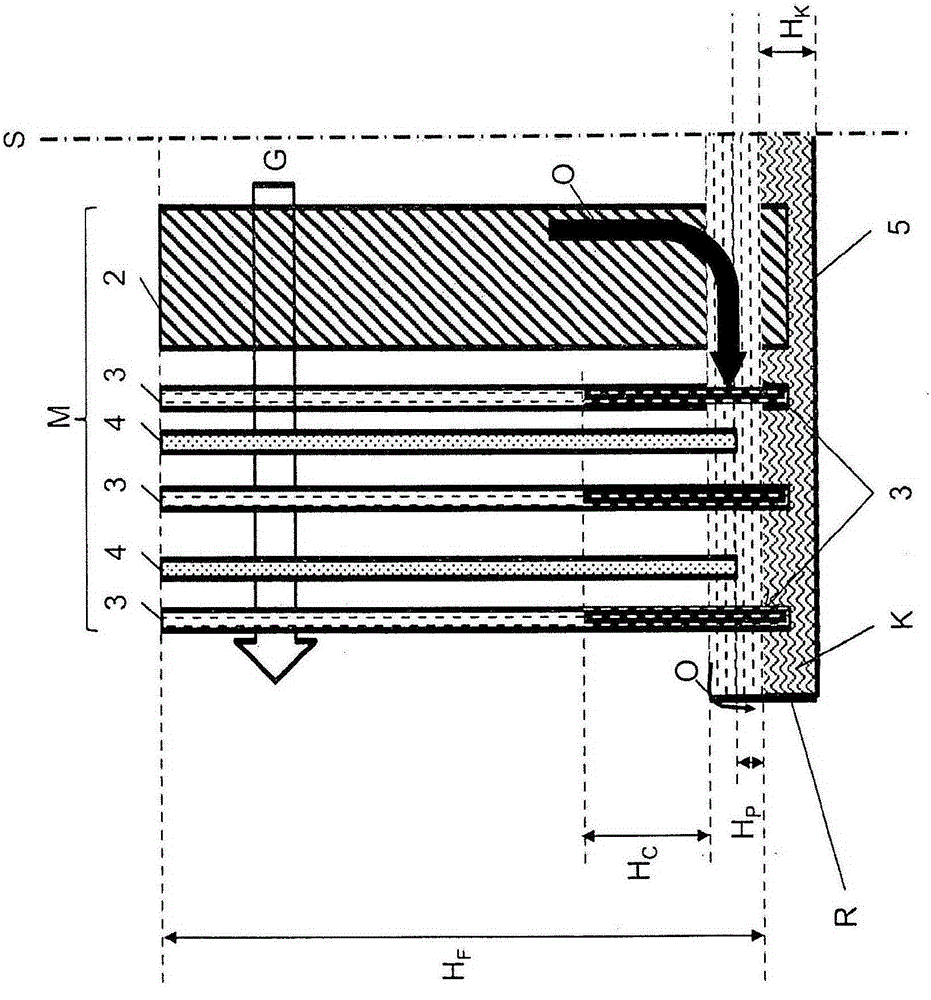

[0048] figure 1 An exemplary embodiment of a filter insert 1 is shown for separating suspended particles of a liquid from a gas flow G, in particular for separating liquid droplets from an aerosol-carrying gas. exist figure 1 The filter insert 1 shown in is of cylindrical design. The symmetry is characterized by the axis of symmetry S. Therefore, only the left half of the rotationally symmetrical structure is shown in the cross-sectional view.

[0049] Individual layers with different filter media can be seen in this arrangement, which together form a media group M. FIG.

[0050] Element 1 has a height H F .

[0051] The gas or gas flow G first flows through the filter medium 2 to then flow through the fine filter 4 via the first filter layer 3 having a capillary effect. Outside this arrangement in the flow direction there is again a layer 3 with a capillary effect, through which layer the now purified gas flow leaves the filter insert 1 .

[0052] The air flow G flows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com