Electromagnetic valve

A solenoid valve and solenoid coil technology, applied in the field of solenoid valves, can solve problems such as hindering the plunger's rushing action, and achieve the effects of easy outflow and reduced pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

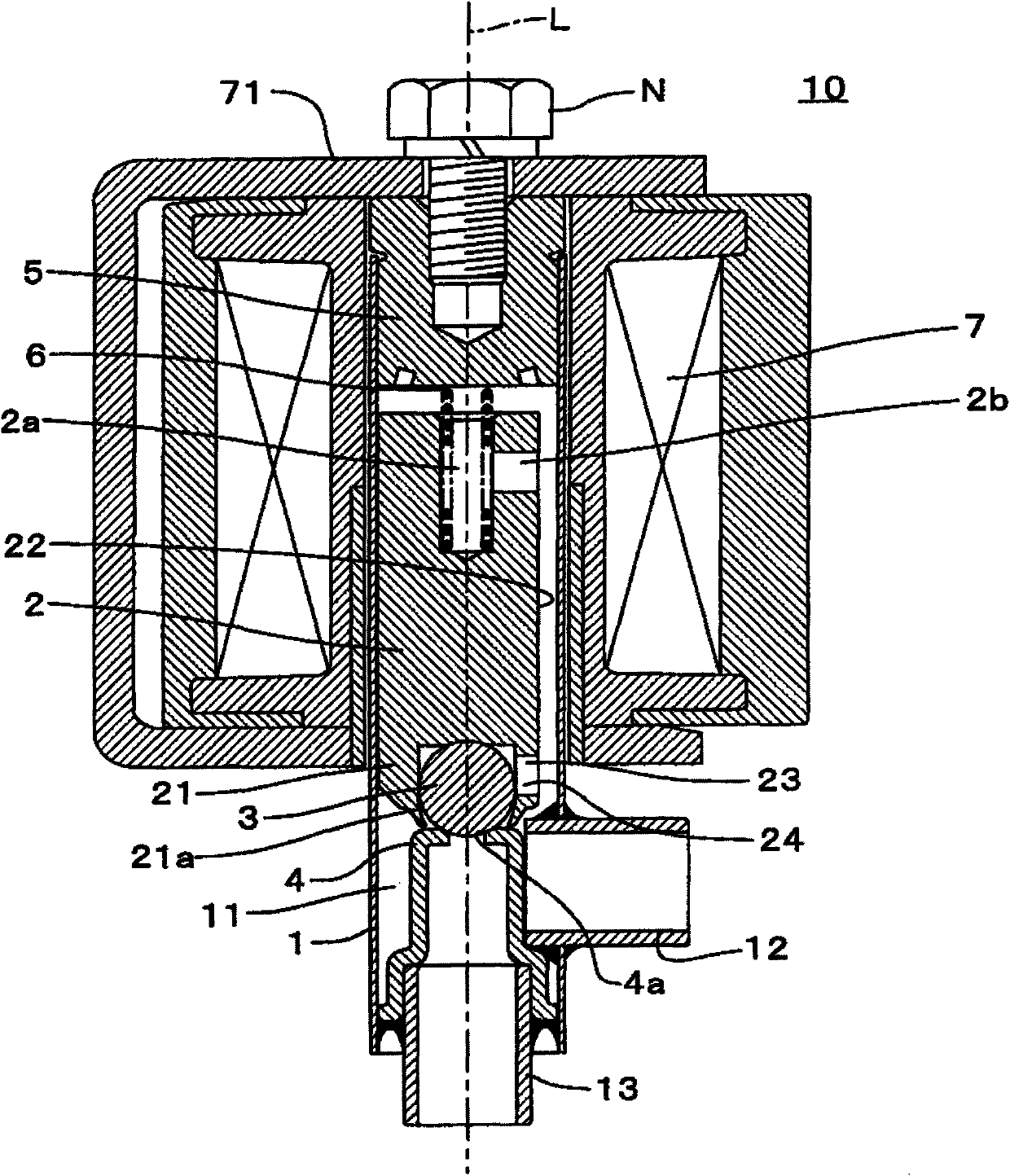

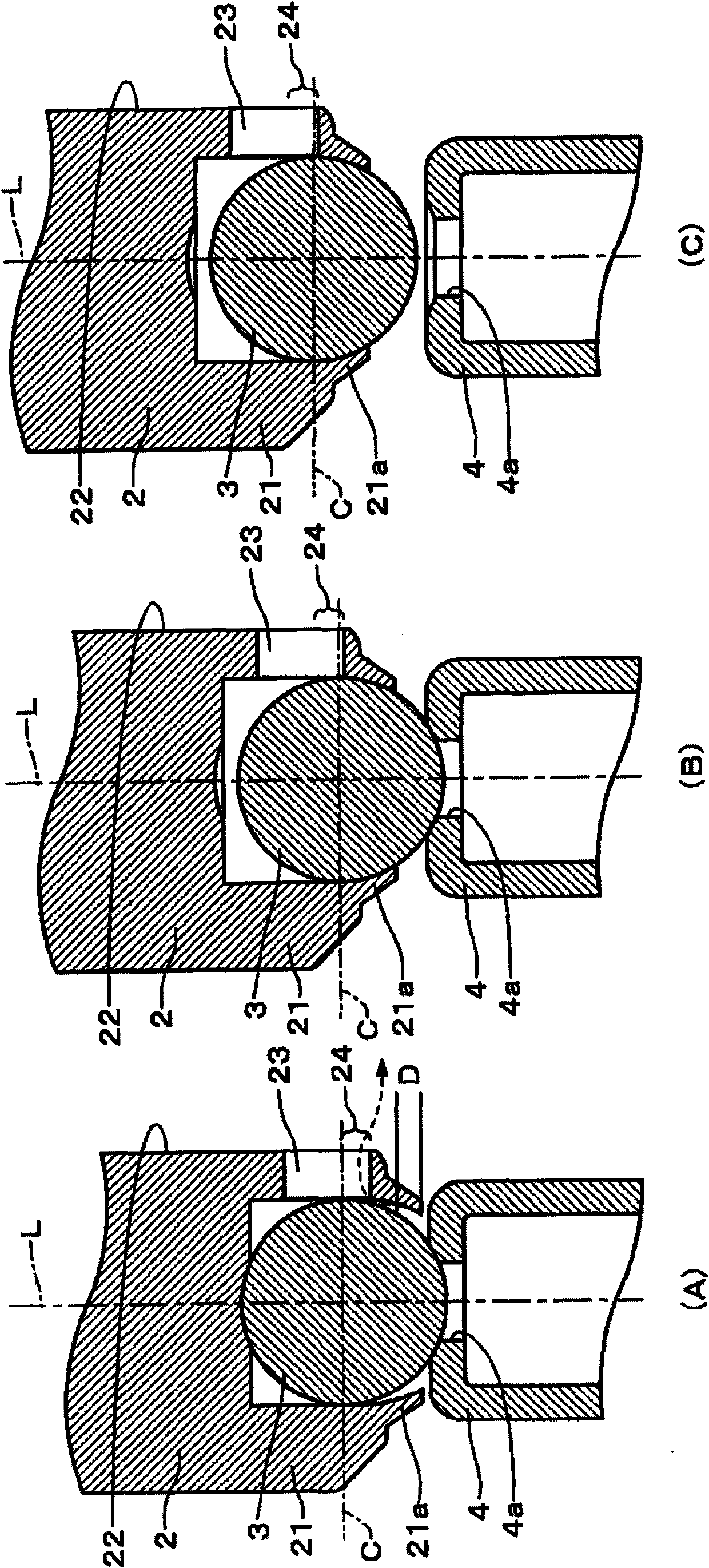

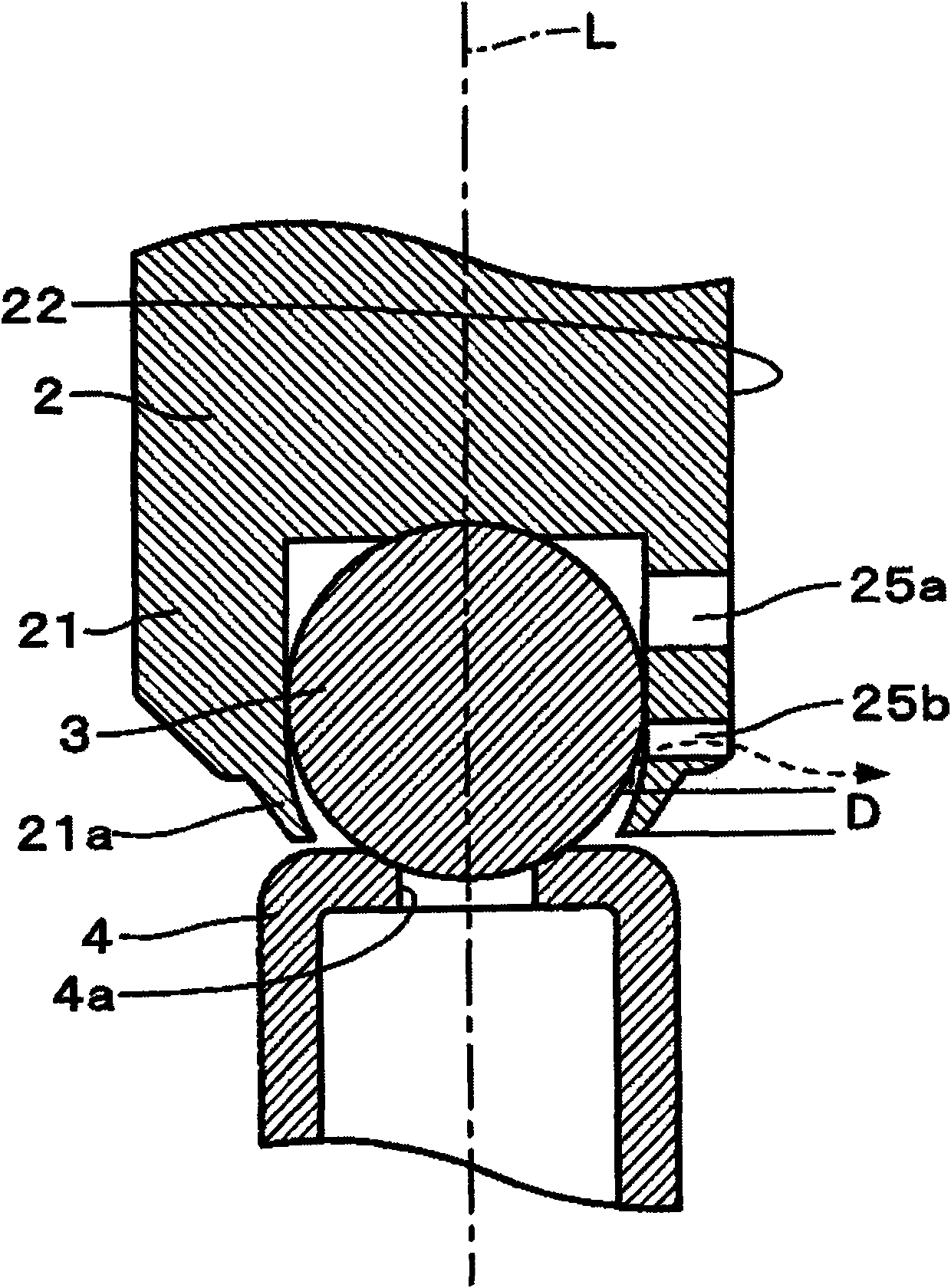

[0029] Next, embodiments of the solenoid valve of the present invention will be described with reference to the drawings. figure 1 is a longitudinal sectional view of the solenoid valve 10 of the embodiment when no power is applied, figure 2 It is an enlarged view of important parts when the solenoid valve 10 operates, figure 2 (A) indicates the state when no power is applied, figure 2 (B) represents the first state at the time of power-on, figure 2 (C) shows the second state at the time of power-on. Such as figure 1 As shown, the solenoid valve 10 of this embodiment includes: a cylindrical plunger tube 1 forming a valve housing 11; a plunger 2 arranged in the plunger tube 1; and a spherical valve element held by the plunger 2. 3; a cylindrical valve seat 4 fitted at the lower end of the plunger tube 1; an attractor 5 fixed at the upper end of the plunger 1; a coil spring 6 compressed between the plunger 2 and the attractor 5; And the electromagnetic coil 7 arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com