Silicon solar cell front conductive silver paste and preparation method thereof

A technology of silicon solar cells and conductive silver paste, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. The problems of sintering and matching of layers of heterogeneous materials can achieve excellent silver burning effect, high electroplating efficiency, and the effect of improving output resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] And, the embodiment of the present invention also provides a method for preparing conductive silver paste on the front side of a silicon solar cell, comprising the following steps:

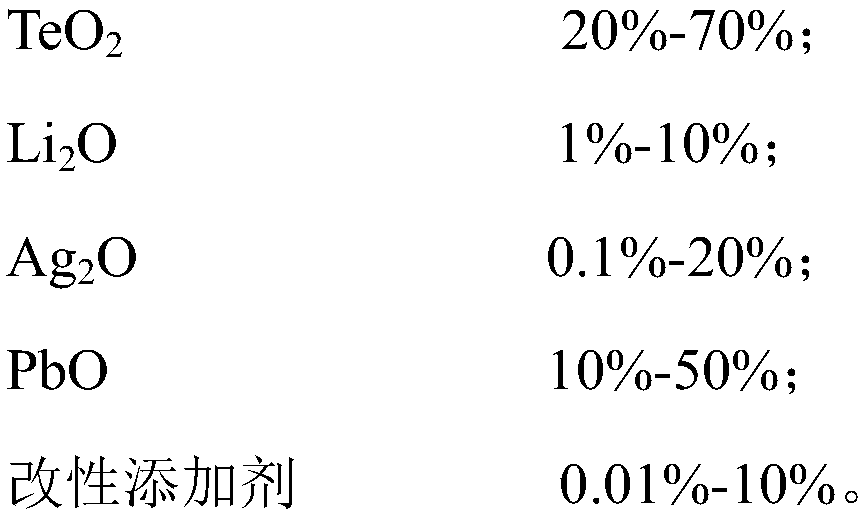

[0045] S01. Preparation of modified TeO 2 -Li 2 O-Ag 2 O-PbO glass powder: The glass frit oxide or the compound that can be decomposed into the inorganic oxide, and the modification additive are weighed, mixed, melted, quenched, crushed, and sieved in order to make a modified TeO 2 -Li 2 O-Ag 2 O-PbO glass powder;

[0046] Specifically, in the above step S01, the types of the glass frit oxide or the compound that can be decomposed into the inorganic oxide, and the modification additive are as described above, and will not be repeated here to save space.

[0047] S02. Preparation of nano-alloy powder coated with organic matter on the surface: mix the elemental powders of Ag, Pb, Bi, and Si according to the ratio, high-temperature melting alloying, cooling, crushing, and sieving, first p...

Embodiment 1-6

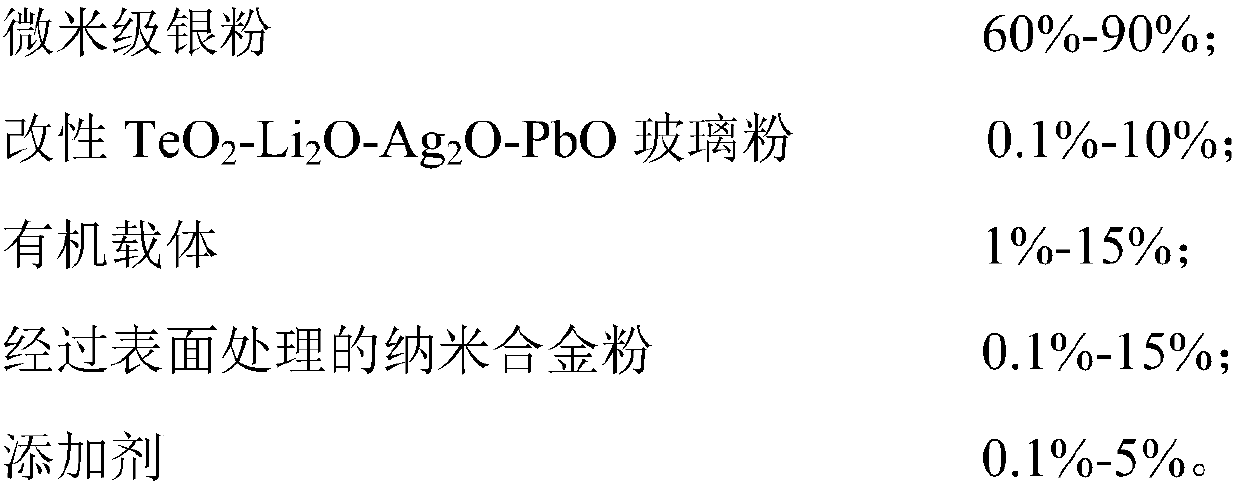

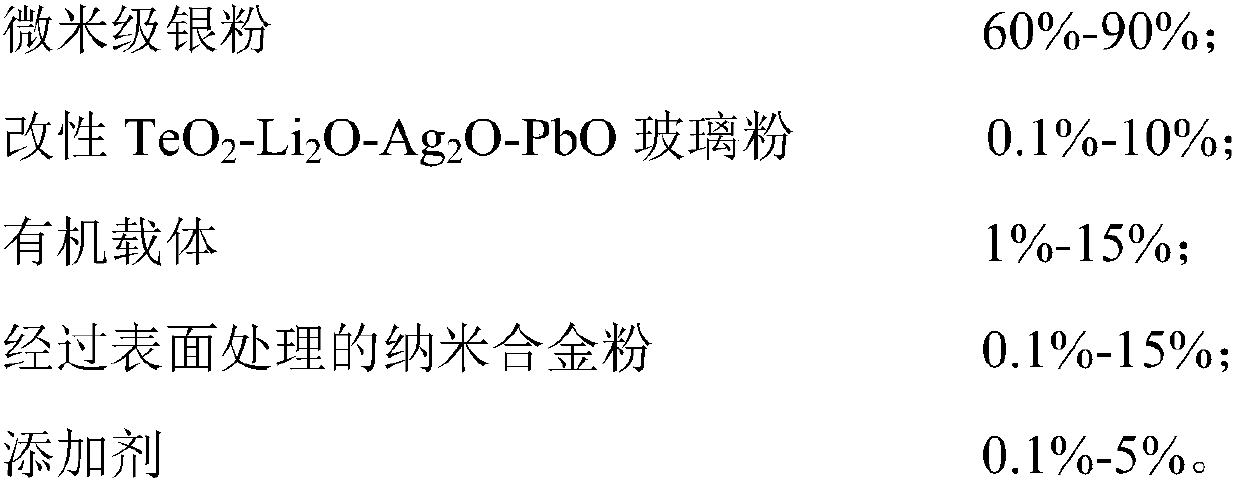

[0058] A conductive silver paste on the front side of a silicon solar cell, including silver powder, glass powder, organic carrier, surface-treated nano-alloy powder, and special additives, the silver powder is micron-scale silver powder, and the glass powder is modified TeO 2 -Li 2 O-Ag 2 O-PbO glass powder, the surface-treated nano-alloy powder is a nano-alloy powder coated with organic matter on the surface, and the special additive is an alkali metal salt plated with silver on the surface. The quality of each component is as follows Table 1. Examples 1-6 Said, the unit in the table is g, wherein, the component numbers correspond to the numbers in Table 2-5 below.

[0059] A preparation method for front conductive silver paste of silicon solar cells, comprising the steps of:

[0060] Modified TeO 2 -Li 2 O-Ag 2 Preparation of O-PbO glass powder: First, weigh the ratio shown in Table 2, the unit in the table is g, ball mill and mix at 150r / min for 60min, then put it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com