Grooving machine

A slotting machine and frame technology, applied in the field of mechanical processing, can solve the problems of difficulty in satisfying the drilling and milling of special slots and single functions, and achieve the effect of meeting the slotting requirements of special slots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

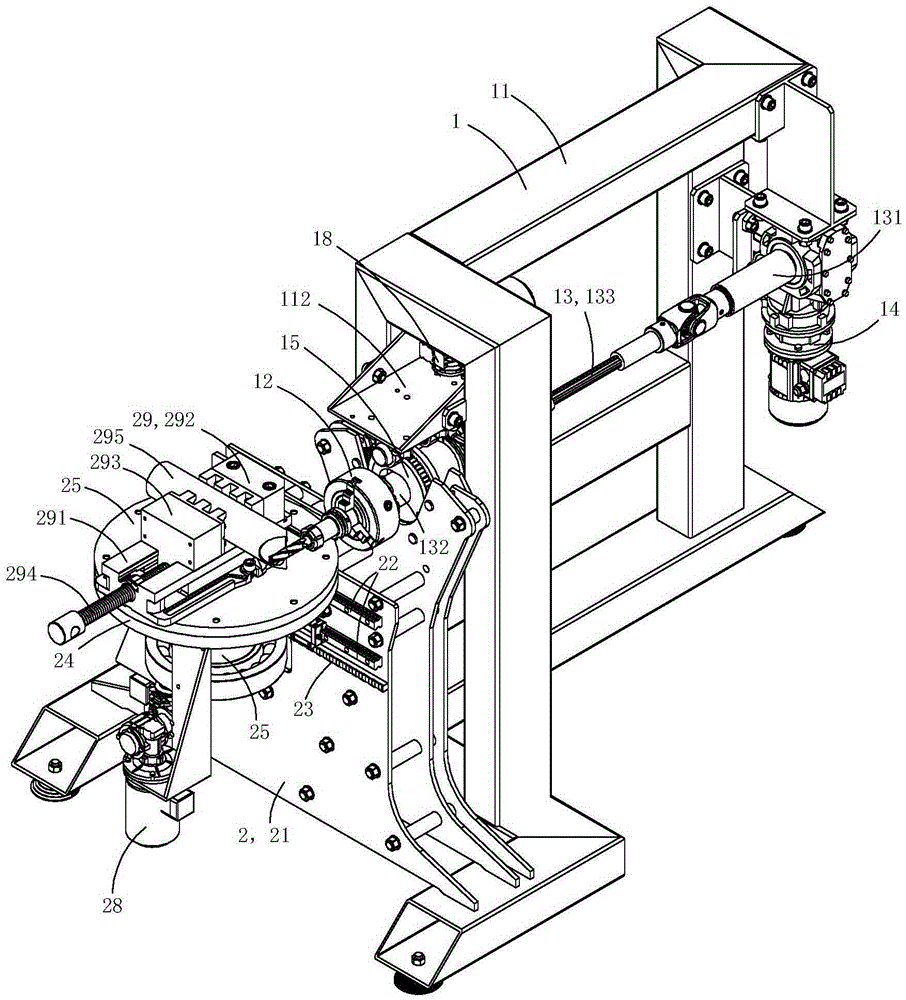

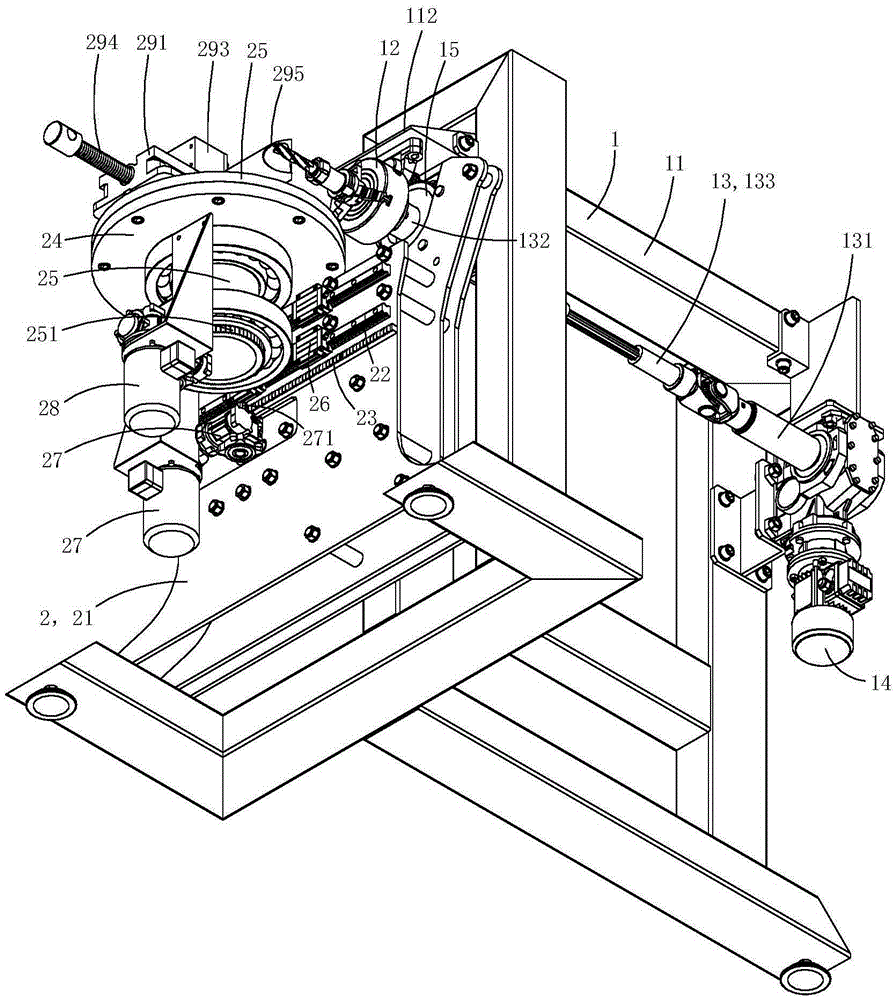

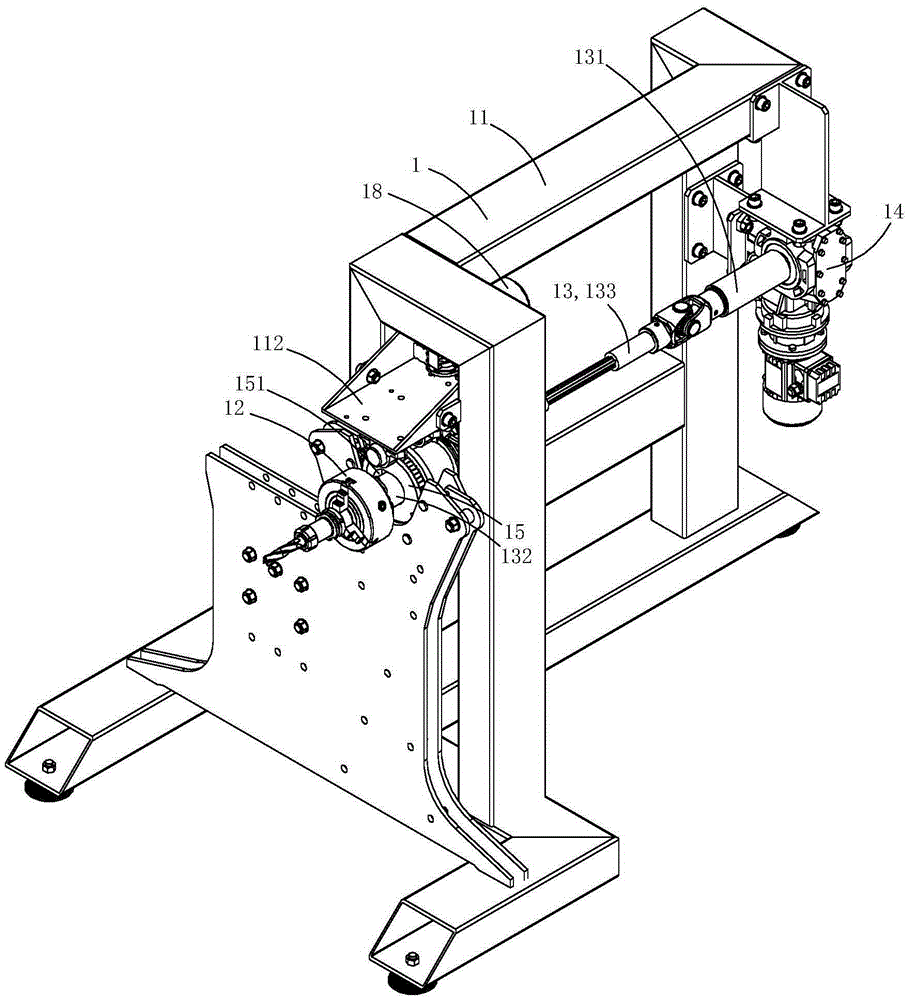

[0014] Figure 1 to Figure 6 One specific embodiment of the invention is shown.

[0015] This embodiment is a slotting machine, see Figure 1 to Figure 6 As shown, it includes a slotting machine body 1 and a tool assembly 2 arranged on the slotting machine body.

[0016] The slotting machine body includes a frame 11, a chuck 12, a main shaft 13 for driving the chuck to rotate, a main drive motor 14 for driving the main shaft to rotate, a limit gear 15 for limiting the swing position of the chuck, and a countershaft 16. The transmission wheel 17 fixedly arranged on the auxiliary shaft for driving the limit gear to rotate, and the auxiliary driving motor 18 for driving the auxiliary shaft to rotate; the auxiliary shaft is arranged along the horizontal line;

[0017] The main shaft is a oscillating main shaft, including a base shaft part 131 fixedly connected to the output shaft of the main drive motor, a working shaft part 132 for driving the chuck to rotate, and a linkage sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com