Automatic packaging system and device thereof

A technology of automatic packaging and transmission device, applied in the field of packaging, can solve the problems of high cost and low efficiency of manual operation, and achieve the effect of improving production efficiency and packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

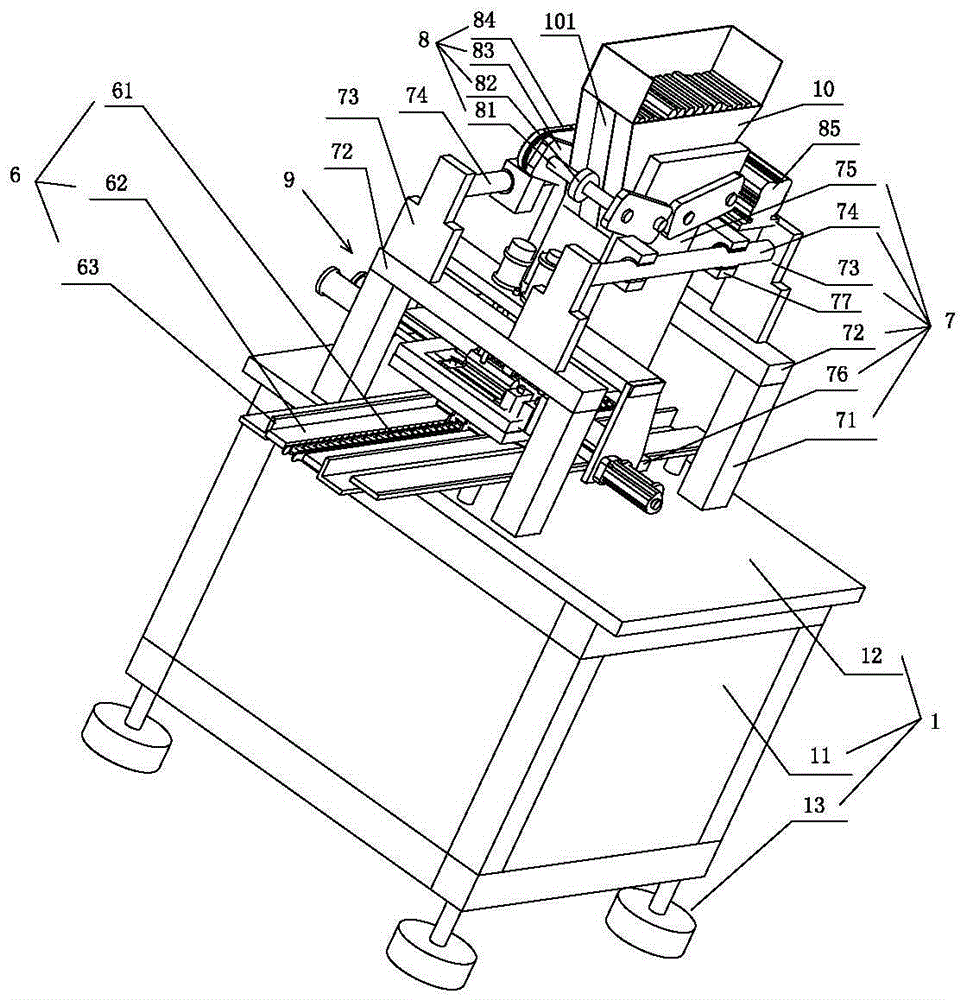

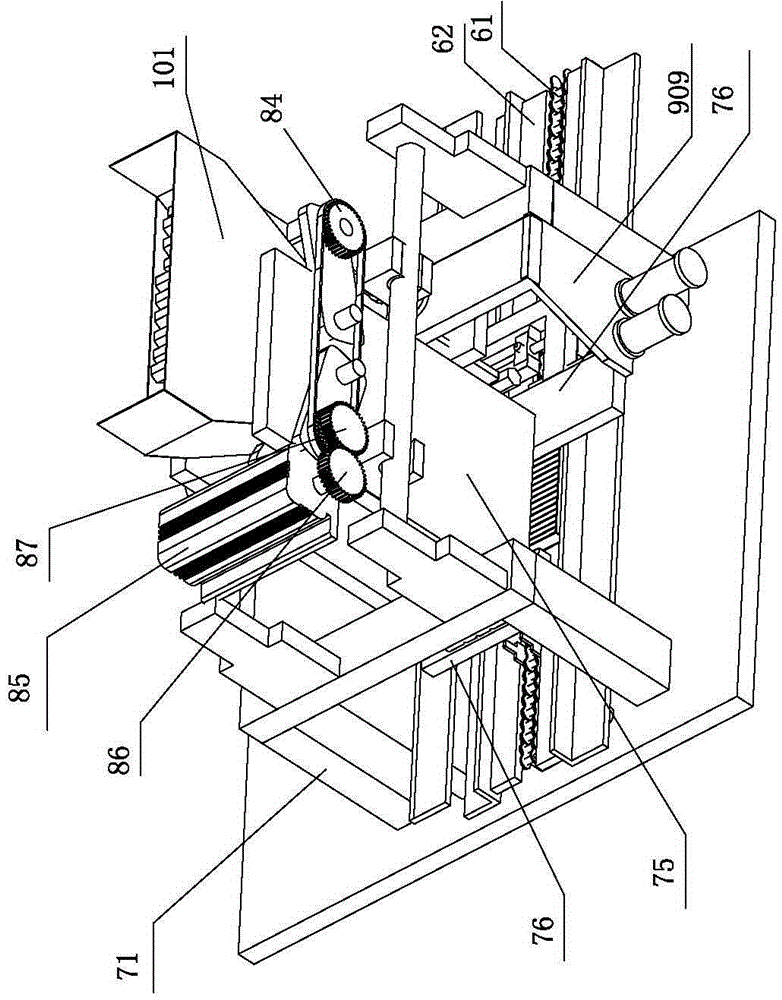

[0039] Example 1: see Figure 2 to Figure 7 .

[0040] An automatic packaging device, comprising

[0041] A hopper 10 for accommodating materials 200, the lower end of the hopper 10 is provided with an outlet;

[0042] The conveying device 2 for conveying the material 200. The conveying device 2 includes a conveying linear module 21 and a push block 22. The push block 22 is located below the outlet. The sex module 21 is driven and connected with the push block 22 and pushes the push block 22 to move back and forth;

[0043] The adjustment mechanism 9 for adjusting the orientation of the material 200; the adjustment mechanism 9 includes an adjustment block 911, the adjustment block 911 is provided with an adjustment space 912 for adjusting the material 200, the adjustment space 912 is located below the moving track of the push block 22, and the adjustment space 912 A correction mechanism for correcting the position of the material 200 is provided on the outside;

[0044] A ...

Embodiment 2

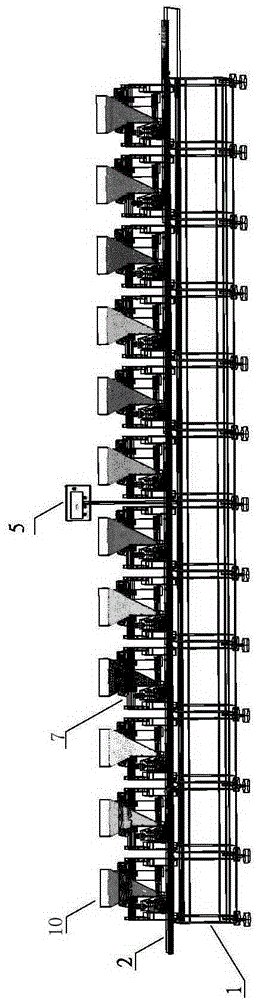

[0069] Example 2: see figure 1 , an automatic packaging system comprising:

[0070] a plurality of the above automatic packaging devices;

[0071] The conveying device 6 is used for conveying the packaging box 100; the conveying device 6 includes a conveying chain 61, which passes through the bottom of each adjusting mechanism 9 in turn, and the two sides of the conveying chain 61 are respectively provided with tray plates 62.

[0072] When packing various materials 200, the conveying device 6 is used to transport the packing box 100, and the packing box 100 is conveyed to the bottom of the adjustment mechanism 9 of each automatic packing device. When the material 200 is loaded into the packing box 100, the conveying chain 61 will The packaging box 100 is conveyed to the next station, thereby forming a production line and improving production efficiency.

[0073] Preferably, the conveying device 6 also includes a servo motor for driving the movement of the conveying chain an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com