Sleeve type fixing device at corner of cantilever scaffold

A technology of cantilevered scaffolding and fixing devices, which is applied to the accessories of scaffolding, building structure support, building structure support, etc., and can solve the problem of increasing the number of pre-buried and fixed, the stability and safety impact of scaffolding, and the height of cantilevered scaffolding. problems, to achieve the effect of reducing potential safety hazards, saving the amount of use, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

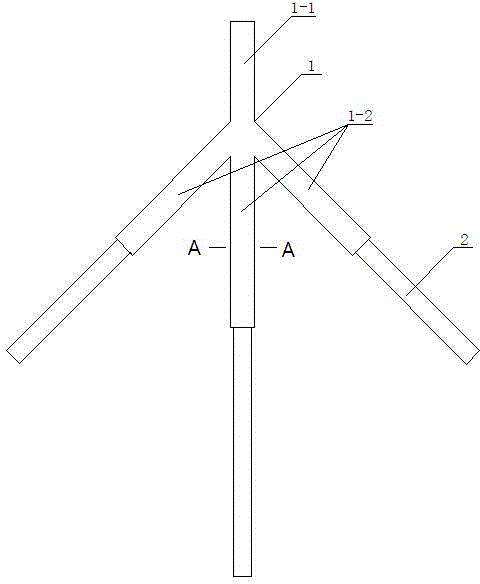

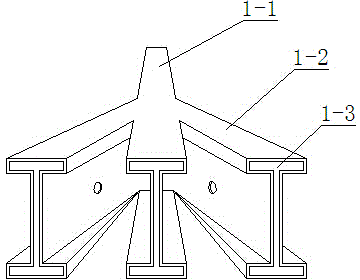

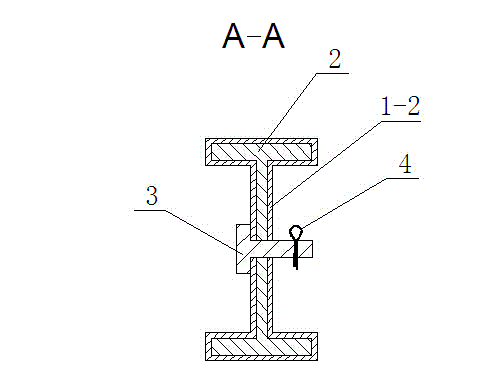

[0013] Such as figure 1 -3 shows the first type of sleeve fixing device at the corner of the overhanging scaffold, which includes a sleeve tool 1 and three I-beams 2. The sleeve tool 1 includes a fixed backbone 1 arranged on the same plane -1 and three I-steel sleeves 1-2, the three I-steel sleeves 1-2 are arranged in a fan shape and are integrally arranged at one end of the fixed trunk 1-1, and each I-steel sleeve 1-2 Set I-shaped cavities 1-3 respectively, three I-beams 2 are respectively inserted into the corresponding I-steel sleeves 1-2 and extend the I-steel sleeves 1-2, and each I-beam 2 is connected to The corresponding I-steel sleeves 1-2 are connected by plug bolts 3 and fixed by split pins 4.

[0014] Such as Figure 4 As shown, there are four I-steel sleeves 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com