Sleeve-combined tool platform for cantilevered scaffolding and its operating method

A technology of cantilevered scaffolding and combined tools, which is applied in the field of cantilevered scaffolding, can solve the problems of low turnover times, low efficiency, and non-adjustable longitudinal distance of vertical poles, and achieve the effects of saving the number of uses, improving installation efficiency, and avoiding cross-arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

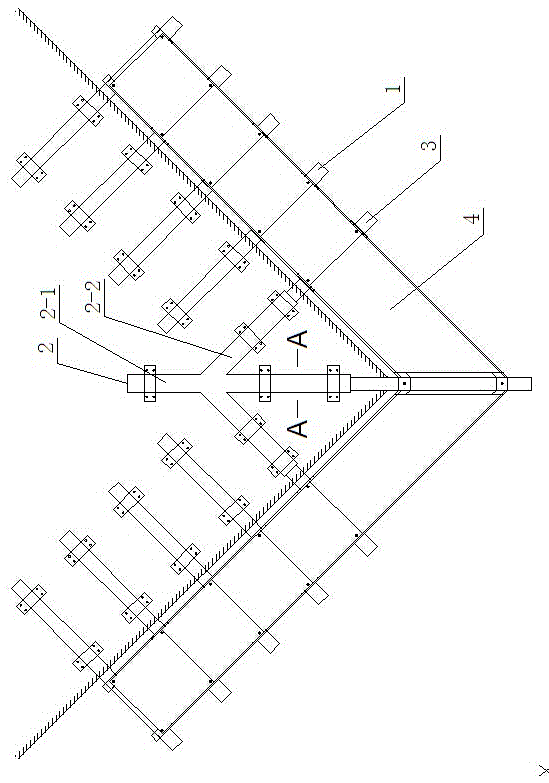

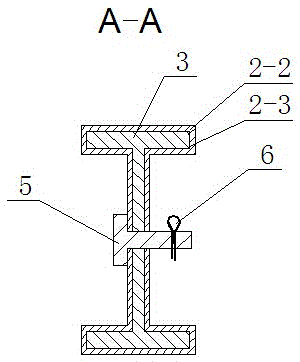

[0033] Such as figure 1 As shown in -10, the present invention mainly includes several intermediate cantilevered I-beams 1 fixed on the floor and sleeve tools 2 fixed at four corners of the floor. The four sleeve tools 2 all include One fixed trunk 2-1 and three I-shaped steel sleeves 2-2 on the plane, the three I-shaped steel sleeves 2-2 are fan-shaped and arranged at one end of the fixed trunk 2-1, each I-shaped The steel sleeves 2-2 are respectively provided with an I-shaped inner cavity 2-3, and each I-shaped steel sleeve 2-2 is respectively inserted with a corner cantilevered I-beam 3, and each corner cantilevered I-beam 3 They are respectively connected with the corresponding I-shaped steel sleeves 2-2 through the first socket bolts 5 and the first cotter pins 6 .

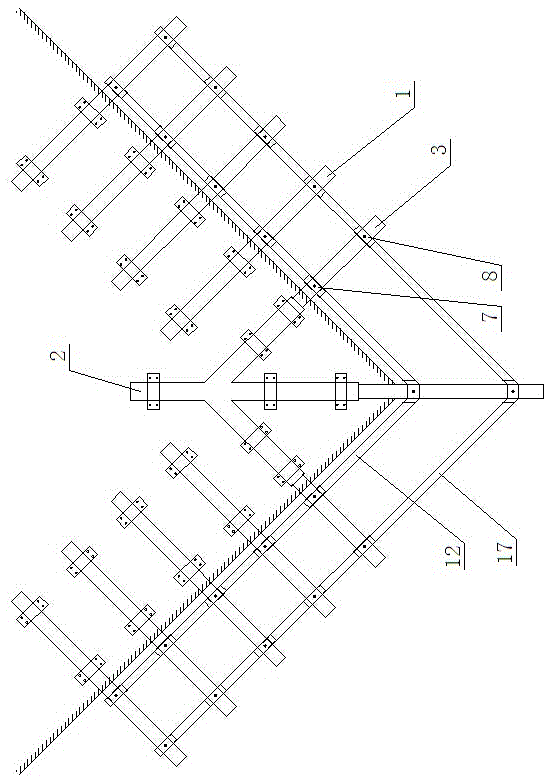

[0034] A rectangular hollow inner sleeve 7 and a rectangular hollow outer sleeve 8 are sleeved on each middle cantilevered I-beam 1 and each corner cantilevered I-beam 3 and are respectively fixed by fasteni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com