Sleeve combination tool type platform of cantilever scaffold and operating method thereof

A technology of cantilevered scaffolding and combined tools, which is applied in the field of cantilevered scaffolding, can solve the problems of low turnover, low efficiency, and inability to adjust the vertical distance of vertical poles, so as to save the amount of use, improve the installation efficiency, and avoid the effect of cross-arrangement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

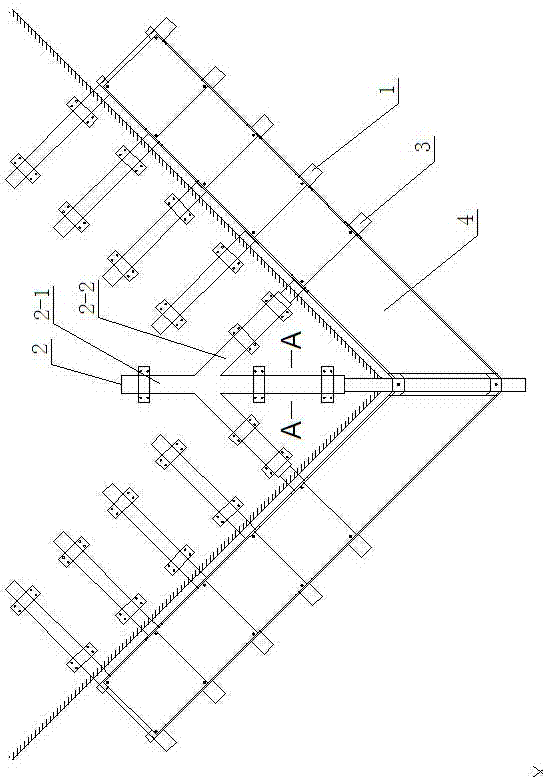

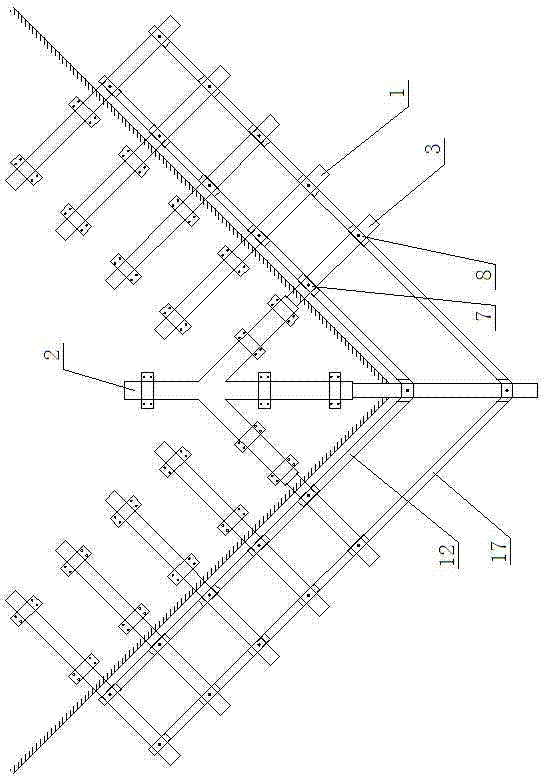

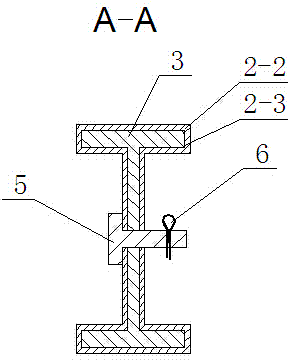

[0033] like figure 1 As shown in -10, the present invention mainly includes several intermediate cantilever I-beams 1 fixed on the floor and sleeve tools 2 fixed at four corners of the floor. A fixed trunk 2-1 and three I-beam sleeves 2-2 on the plane. The three I-beam sleeves 2-2 are fan-shaped and integrally arranged at one end of the fixed trunk 2-1. An I-shaped inner cavity 2-3 is respectively arranged in the steel sleeve 2-2, and a corner cantilevered I-beam 3 is respectively inserted in each I-beam sleeve 2-2, and each corner cantilevered I-beam 3 They are respectively connected with the corresponding I-beam sleeves 2 - 2 through the first plug bolts 5 and the first split pins 6 .

[0034] A rectangular hollow inner sleeve 7 and a rectangular hollow outer sleeve 8 are sleeved on each middle cantilevered I-beam 3 and each corner cantilevered I-beam 1 and fixed by fastening bolts 9 respectively. The upper end of each rectangular hollow inner sleeve 7 is respectively fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com