Rapid mounting and dismounting structure for oil screen of extractor hood

An oil net and oil fume absorption technology, applied in the field of range hood parts, can solve the problems of easy falling of screws, difficult disassembly, increase inconvenience, etc., to prevent falling and loss, simple structure, quick and easy disassembly and assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

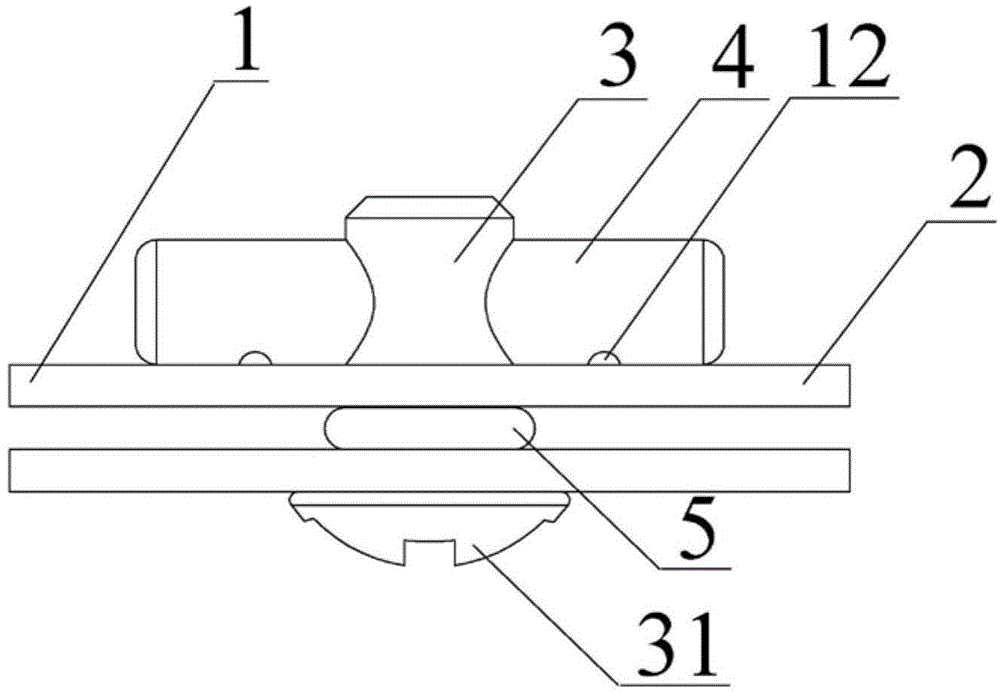

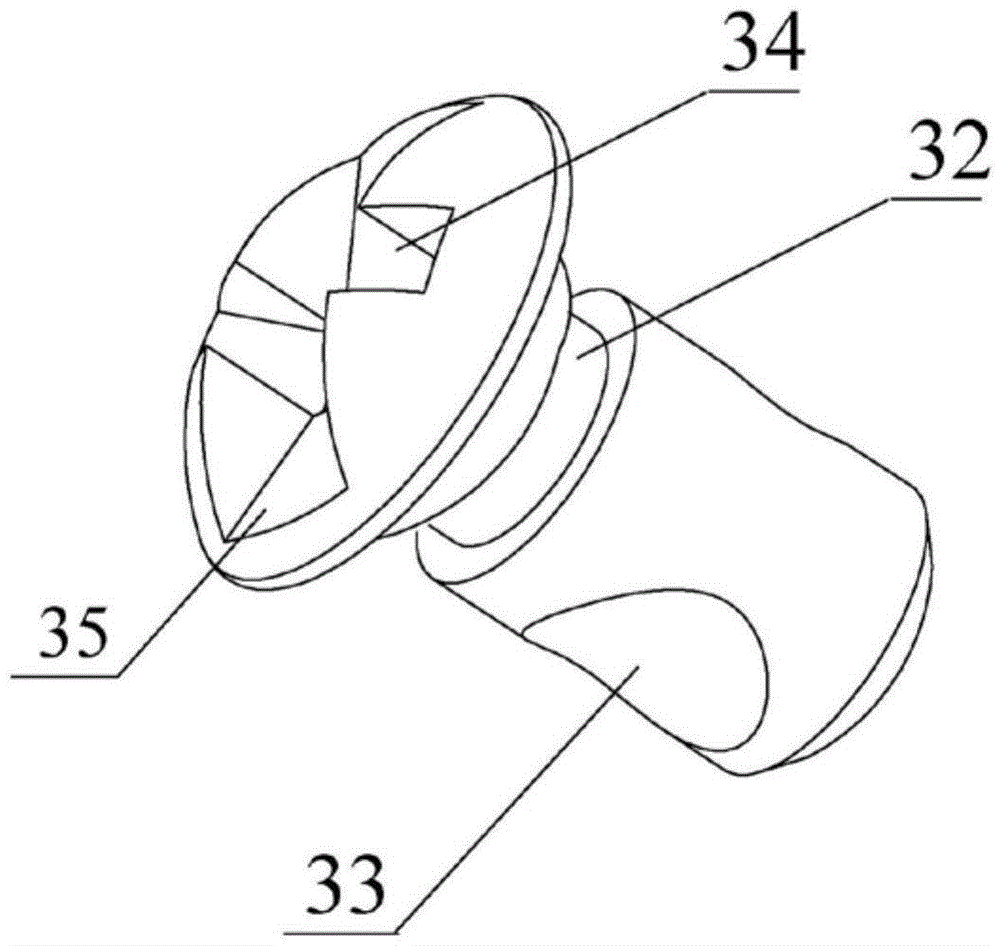

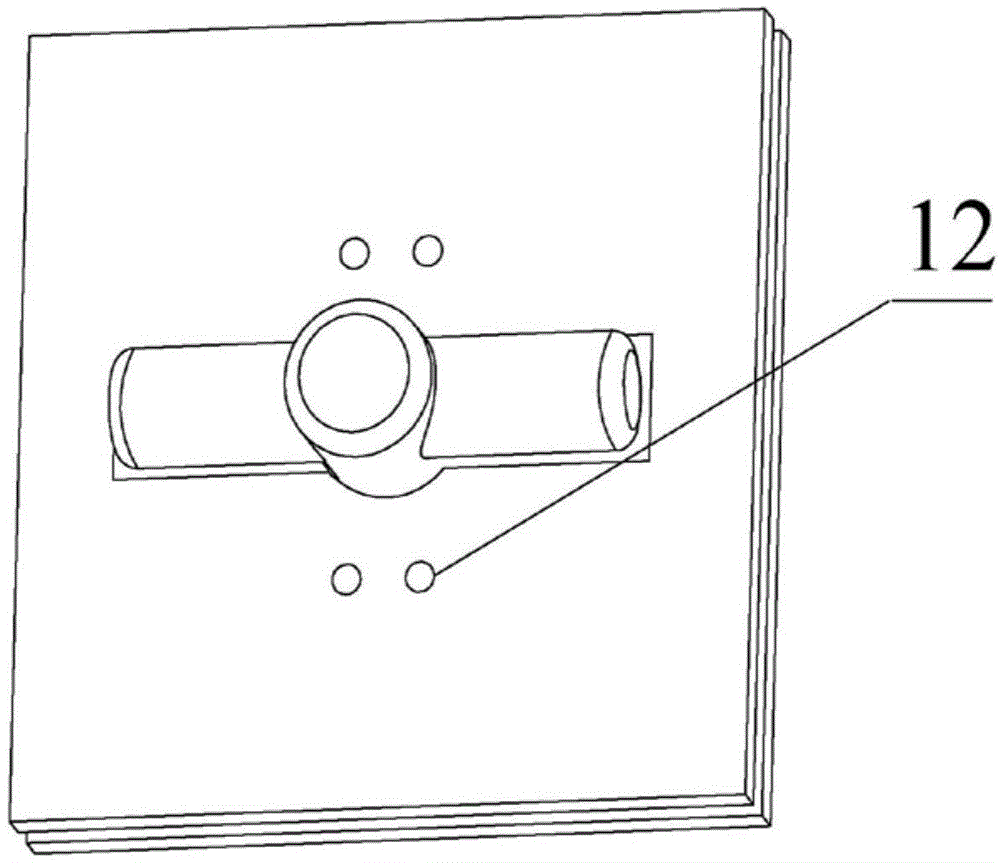

[0024] combine Figure 1 to Figure 4 The present invention is described in further detail.

[0025] A quick disassembly and assembly structure for the oil net of a range hood, including a middle frame plate 1 positioned and installed on the smoke collecting cavity, an oil net 2 arranged under the middle frame plate, and a tail part pierced with a fixing pin 4 quick-release screw 3, the central axis of the fixing pin 4 is parallel to the middle frame plate and perpendicular to the central axis of the quick-release screw, and the quick-release screw 3 passes through the oil screen 2 and the middle frame sequentially from bottom to top The plate 1 and the fixed pin 4 stop on the side of the middle frame plate facing away from the oil screen. An elastic stop ring 5 is inserted between the middle frame plate 1 and the oil screen 2. The stop ring is sleeved on the fast Remove screw 3.

[0026] The structure that the stop ring 5 is sleeved on the quick release screw 3 is: a groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com