Vibration quality detection system and method

A vibration quality and detection system technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as low efficiency, low degree of automation in vibration industry quality inspection, and difficulty in data aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

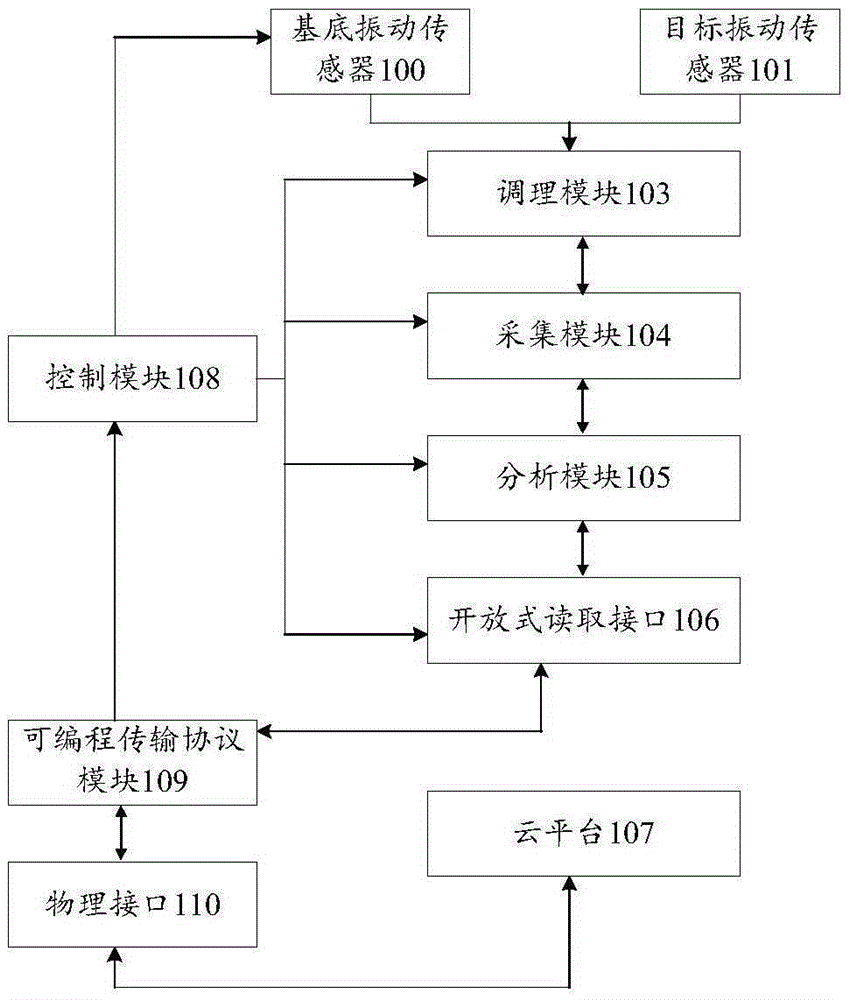

[0035] Such as figure 1 As shown, an embodiment of the present invention provides a vibration quality detection system, and the system includes:

[0036] The base vibration sensor 100 is used for background vibration subtraction. The base vibration sensor 100 is installed on the base of the vibration assembly test bench on the production line of the target detection product, and the base vibration sensor 100 may be provided on multiple channels for background vibration subtraction.

[0037] The target vibration sensor 101 is used to measure the vibration of a target object. The target vibration sensor 101 is installed on the vibration part of the target detection product, and the target vibration sensor 101 may be set on multiple channels to measure the vibration of the target object. For example, when the target detection product is an air conditioner, the The target vibration sensor 101 is placed at the place where the copper pipe of the air conditioner is welded to the elbow, b...

Embodiment 2

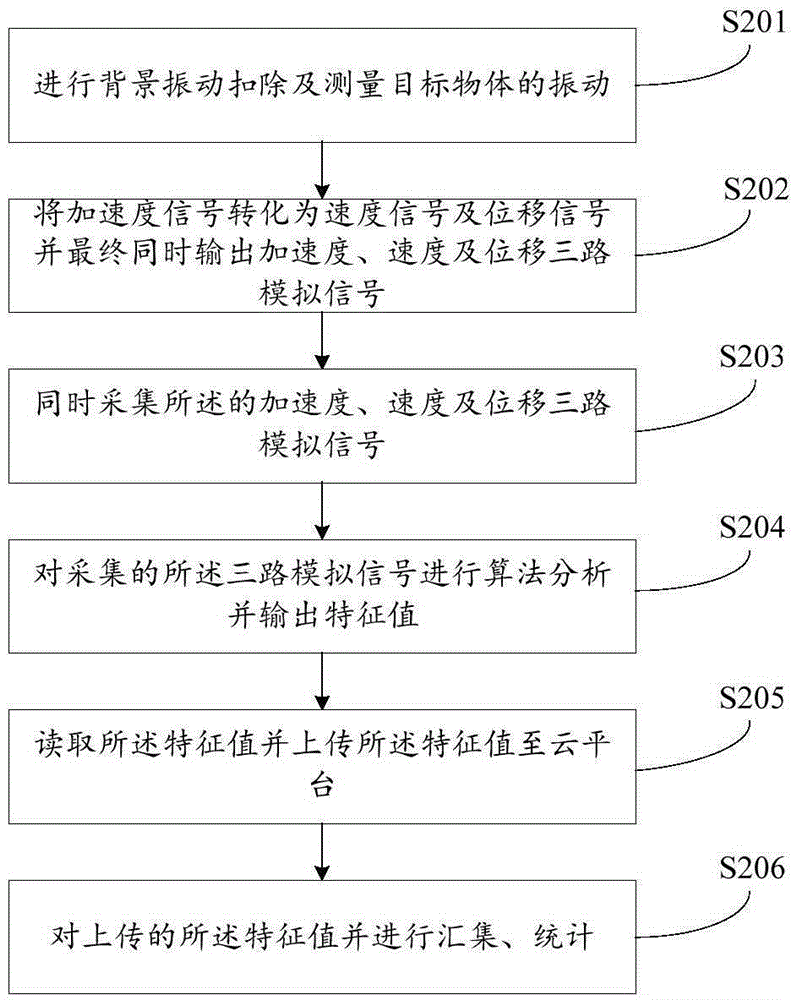

[0050] Such as figure 2 As shown, the embodiment of the present invention provides a vibration quality detection method, and the method includes the following steps:

[0051] S201: Perform background vibration subtraction and measure the vibration of the target object.

[0052] S202: Convert the acceleration signal into a speed signal and a displacement signal, and finally output three analog signals of acceleration, speed and displacement at the same time.

[0053] S203: Collect the three analog signals of acceleration, velocity and displacement at the same time.

[0054] S204: Perform algorithmic analysis on the collected three-channel analog signals and output characteristic values.

[0055] S205: Read the characteristic value and upload the characteristic value to a cloud platform.

[0056] S206. Collect and make statistics on the uploaded feature values.

[0057] The background vibration is subtracted by the base vibration sensor, and the vibration of the target object is measured b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com