Method for fast switching from process and performance requirements to design parameter of injection molding equipment

A design parameter and fast conversion technology, applied in computer-aided design, calculation, electrical digital data processing, etc., can solve the problems of low design efficiency, difficulty in adapting to the diversified requirements of customers, and retention, so as to achieve reasonable conversion results and improve design The effect of efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

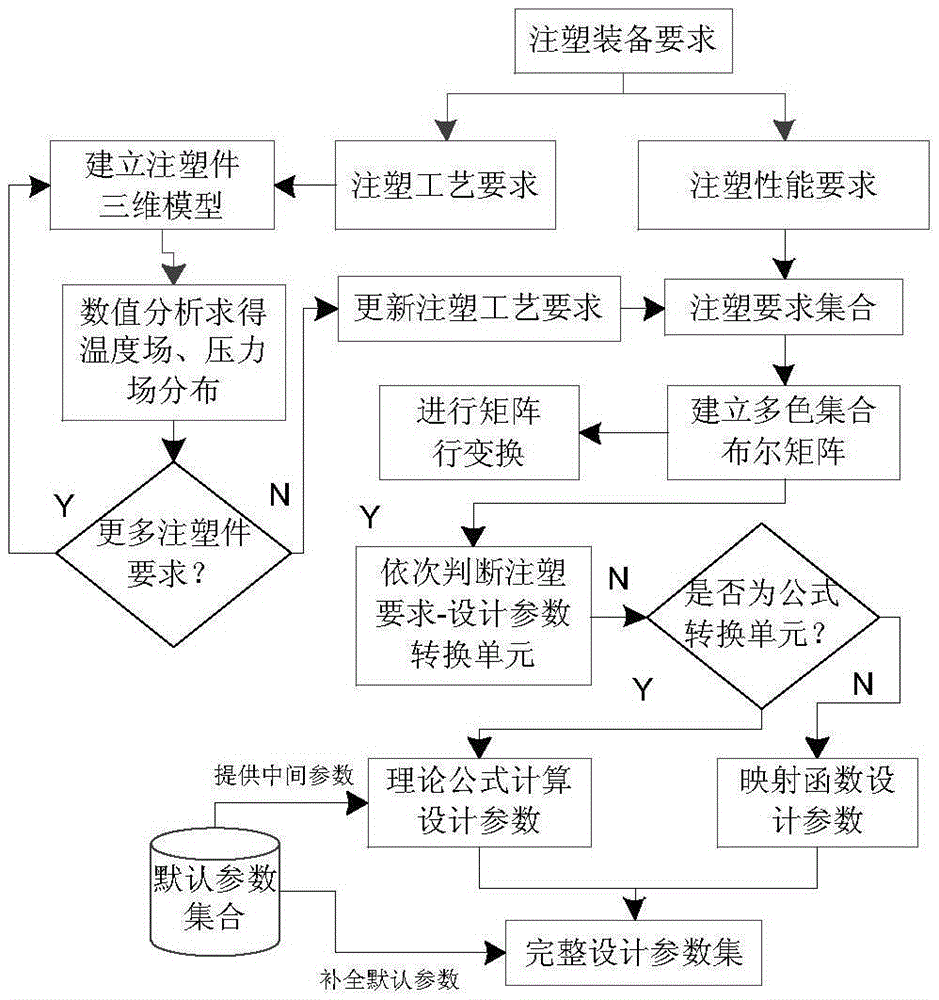

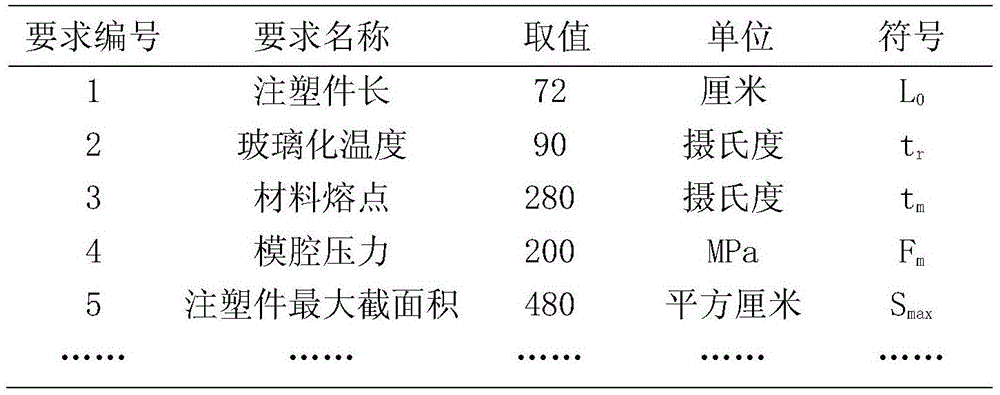

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The information involved in the figures is the actual application data of the present invention in the design of injection molding equipment.

[0041] like figure 1 Shown is the general diagram of the conversion process of the present invention.

[0042]Concrete embodiment of the present invention and process thereof are as follows:

[0043] The first step is to establish a three-dimensional model and conduct numerical simulation analysis according to various injection molded parts required by injection molding to obtain the process requirements of injection molding equipment;

[0044] In the second step, according to the requirement information input by the user, after eliminating conflicts, deficiencies, and redundant data in the requirements, it is mapped to the performance requirements of injection molding equipment, and together with the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com