Moving walkway pallets for moving walkways

A technology for moving trails and pallets, used in escalators, transportation and packaging, and can solve problems such as huge acceleration and deceleration forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

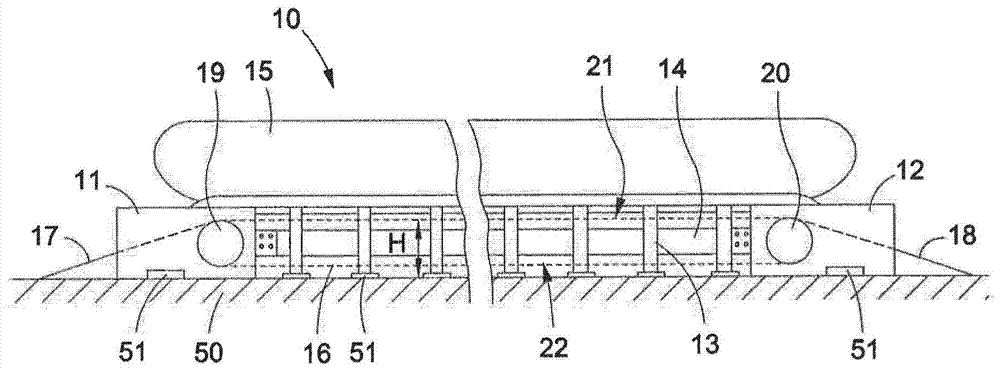

[0030] figure 1 A moving walkway 10 is shown schematically in side view, which is arranged on a load-bearing structure 50 . As the load-bearing structure 50 is, for example, ground or a concrete foundation of sufficient strength. Of course, steel frames, steel bearing parts, cement slopes, etc. can also be considered as load-bearing structures. The floor has receptacles 51 on which the components of the mobile walkway 10 are fixed. The aforementioned components include a first deflection area 11 and a second deflection area 12 as well as a support structure 13 arranged between the deflection areas 11 , 12 , a running rail 14 , a guardrail 15 and a pallet belt 16 . The deflection sprockets 19 , 20 are rotatably mounted in the deflection regions 11 , 12 , around which the pallet belt 16 is guided to revolve. The pallet strips 16 respectively form a forward run 21 on which users can step and a return run 22 for guiding back the moving walkway pallets. In addition, ramps 17 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com