A dynamic prestressed clamping device for spinal implants and its installation method

A clamping device and prestressing technology, applied in the direction of spinal implants, joint implants, joint implants, etc., can solve problems such as vertebral tension, compression force, shear force and torque cannot be effectively transmitted, Achieve the effect of reducing the risk of slippage and improving effective transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

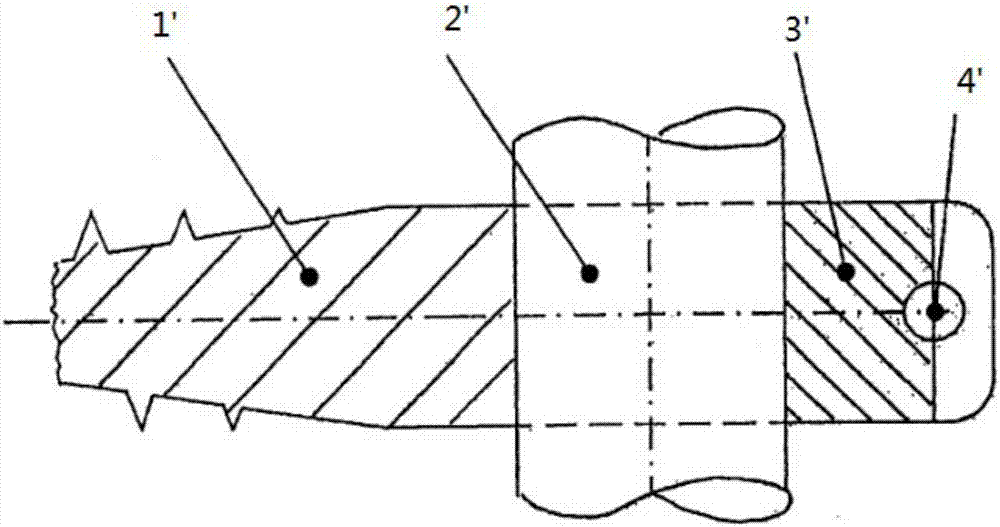

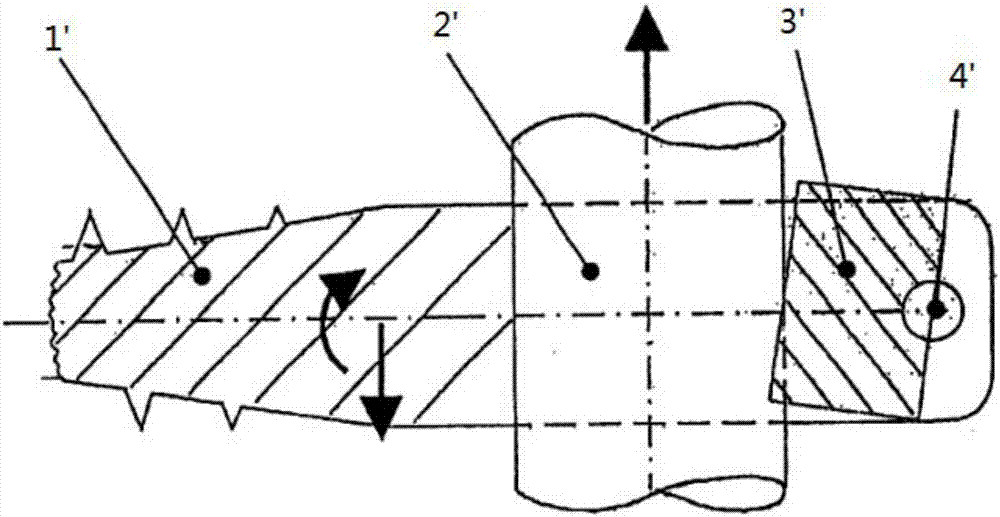

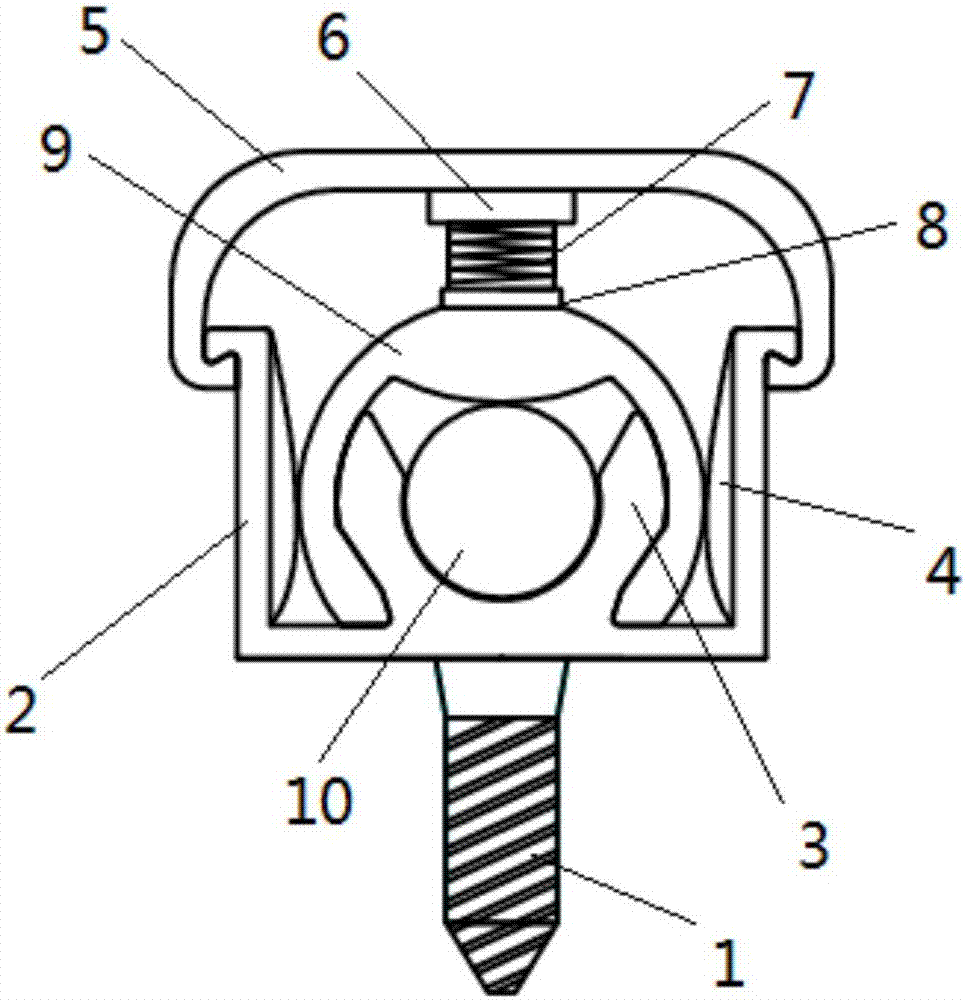

[0052] The present invention will be further described below with reference to the drawings and embodiments.

[0053] Such as Figure 1-3 As shown, a dynamic pre-stress clamping device for spinal implants includes a screw 1, a U-shaped member 2, a support 3, a cover plate 5, a pre-stress member 7 and a clamping member 9. The U-shaped member 2 includes a U-shaped member bottom plate 21 and two U-shaped member side walls 22 extending upward from the U-shaped member bottom plate 21. The bottoms of the two U-shaped side walls 22 are respectively connected to the corresponding ends of the U-shaped bottom plate 21; the tops of the U-shaped side walls 22 respectively extend outward, and side wall inverted teeth 23 are formed at the ends. The inner surface of the side wall 22 of the U-shaped member is respectively provided with pressing blocks 4 protruding inward. The bottom surface of the U-shaped member bottom plate 21 is fixed with the connecting screw 1; The support 3 includes two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com