Mold with mechanical reverse ejecting mechanism

A kind of anti-jack mechanism and mechanical technology, which is applied in the field of molds with mechanical anti-jack mechanism, can solve the problems of high cost of multi-color injection molds, and achieve the effect of reducing the cost of the mold and the complexity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

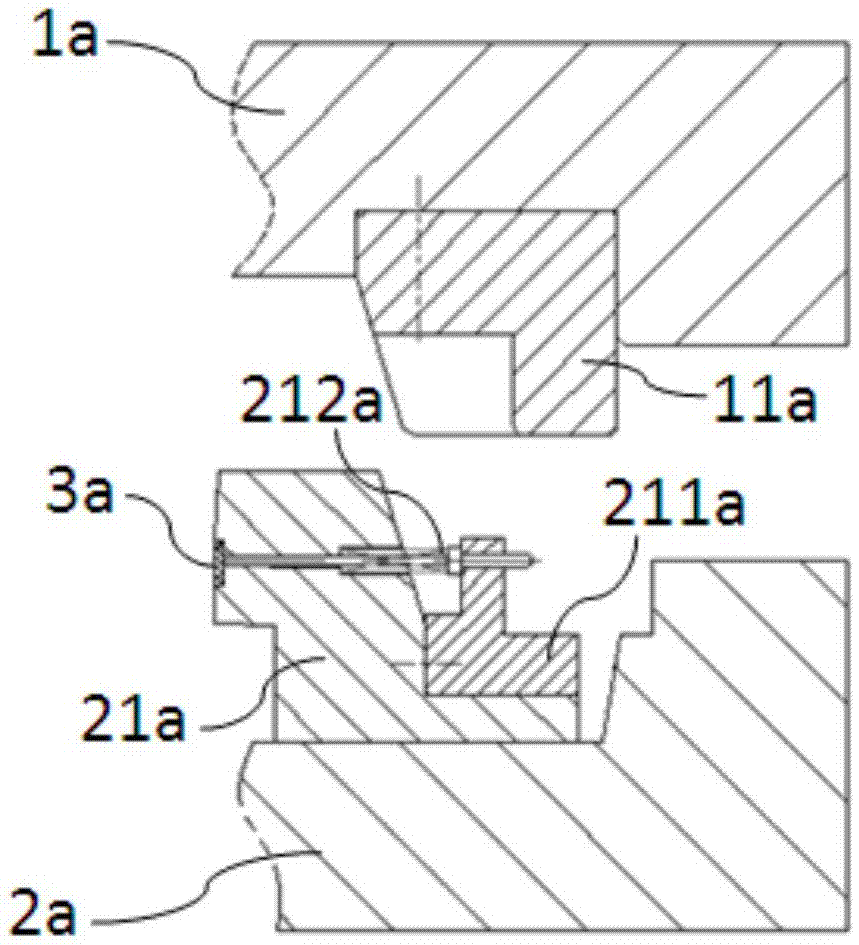

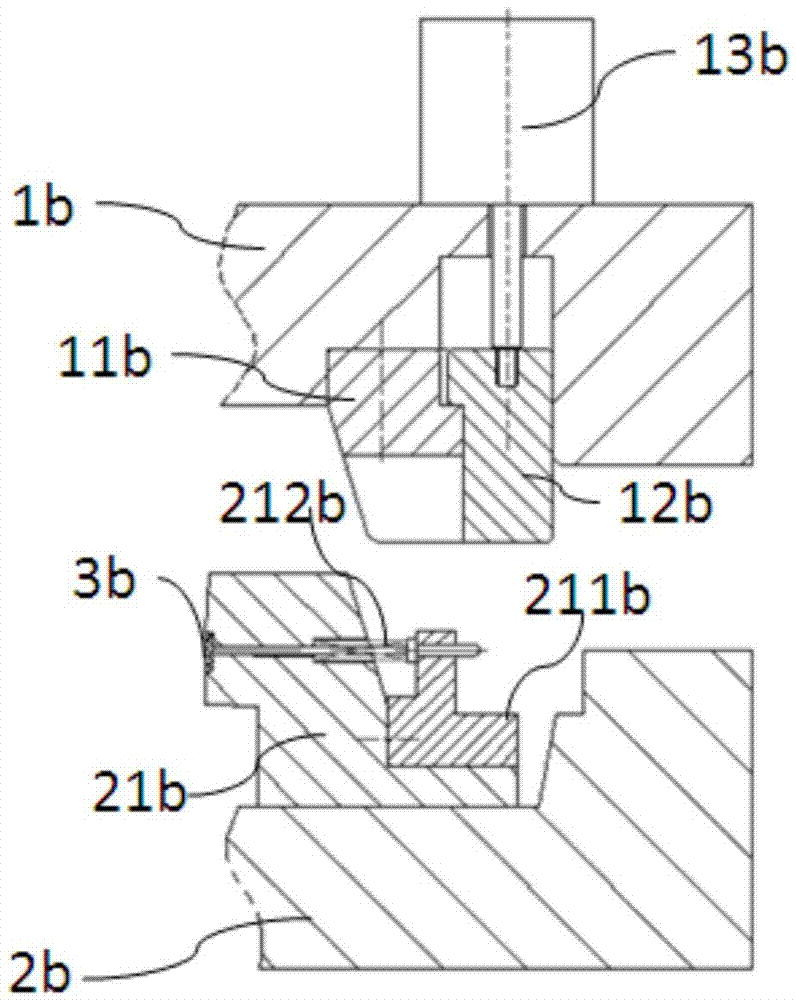

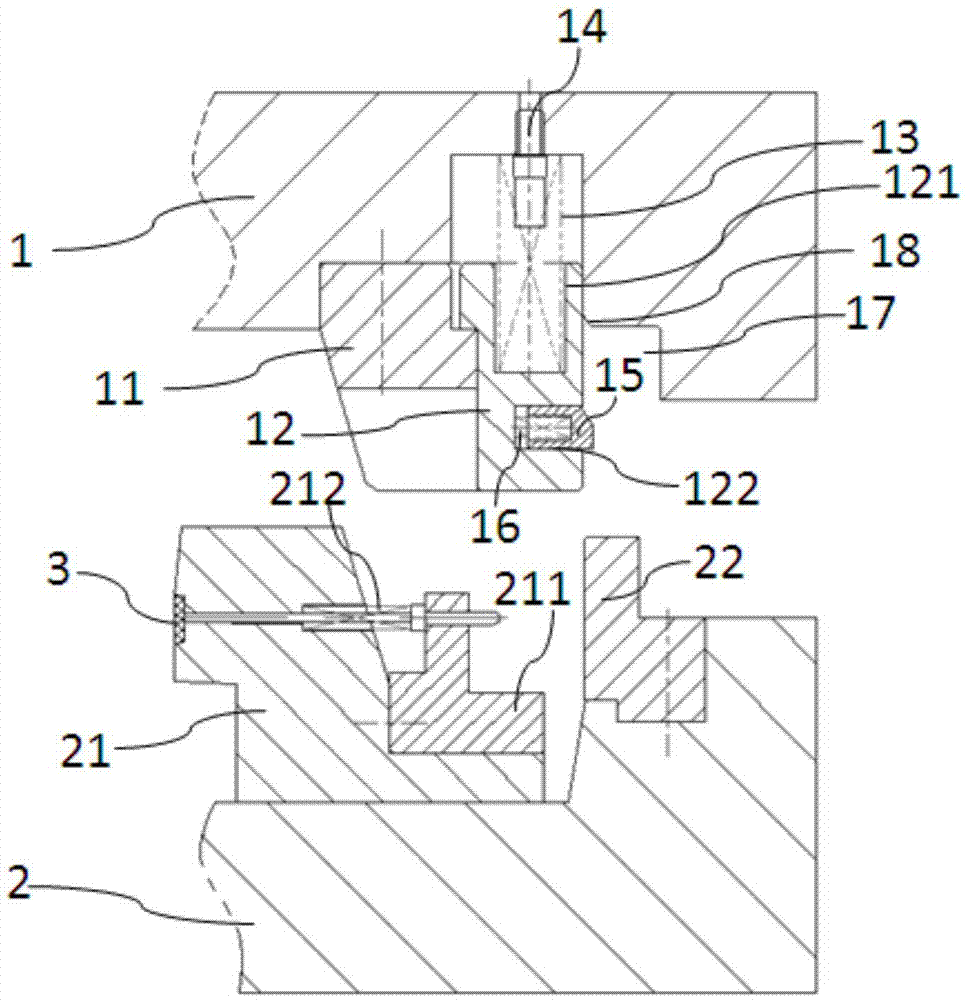

[0022] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

[0023] Herein, "up", "down", "left", and "right" are only used to indicate the direction of relative movement for convenience when describing the embodiments in conjunction with the drawings, and are not specifically limited to this direction.

[0024] Such as image 3 As shown, the mold with mechanical reverse ejection mechanism according to the present invention has locking block 11, reverse ejector block 12, slide block 21, fixed block 211 and anti ejector pin similarly to the existing mold with hydraulic type reverse ejector structure 212. Specifically, the fixed mold 1 is provided with a locking block 11 and an anti-jack block 12, the locking block 11 is fixedly connected to the fixed mold 1, and the anti-jack block 12 can move up and down relative to the fixed mold 1; The inclined guide column is provided with a slide block 21 , on which a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com