Curtain rolling travel control structure

A stroke control and curtain technology, applied in the direction of windows/doors, building components, building structures, etc., can solve the problems of gap friction, small volume of ball 90, increase manufacturing cost, etc., to reduce the difficulty of structural assembly and reduce the obvious step difference , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

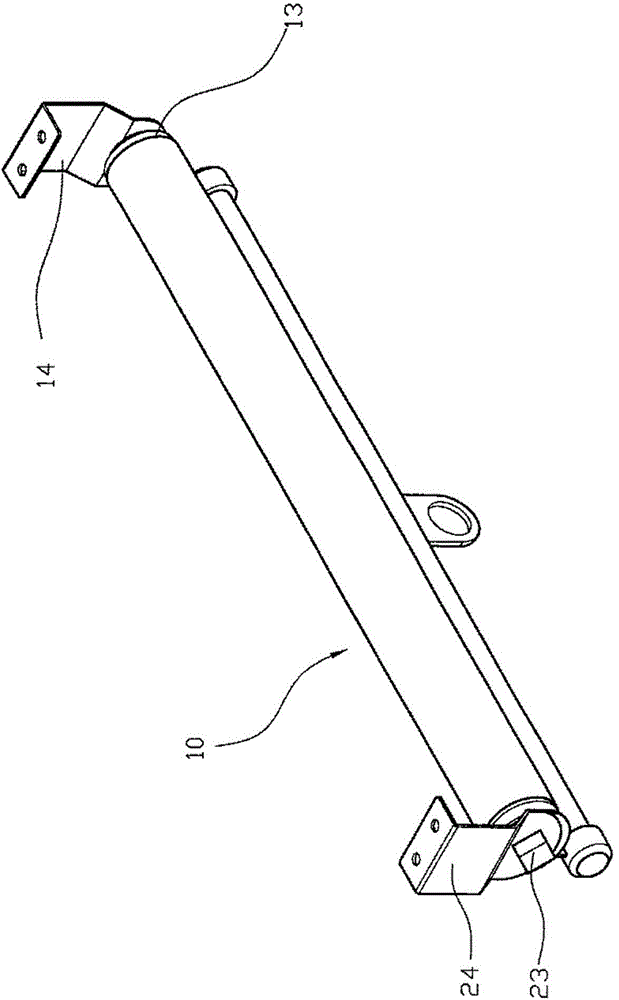

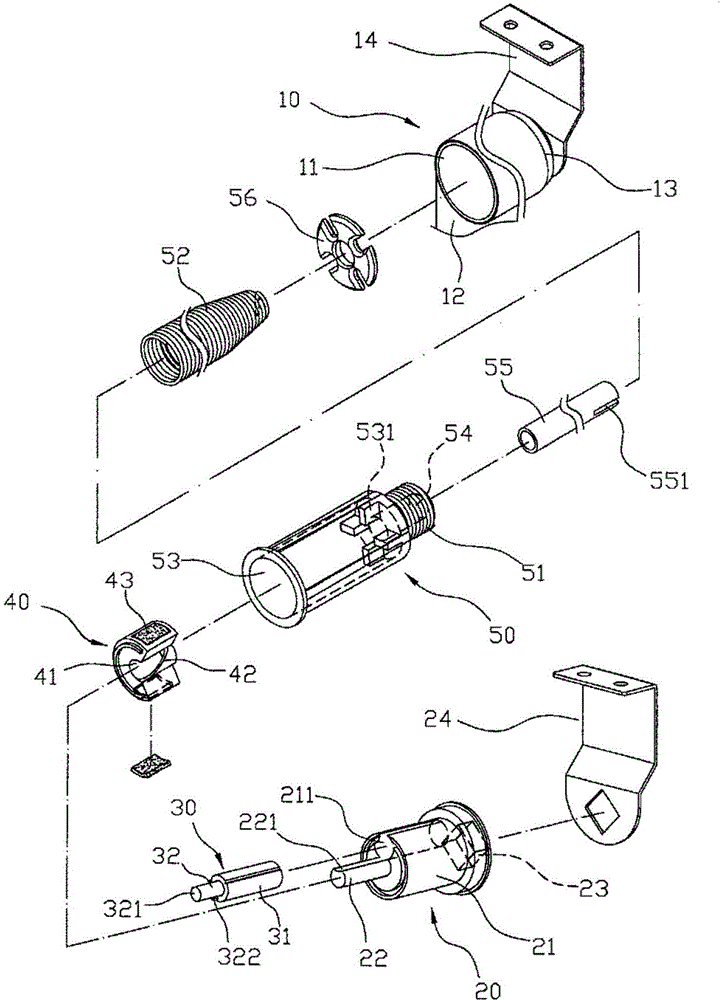

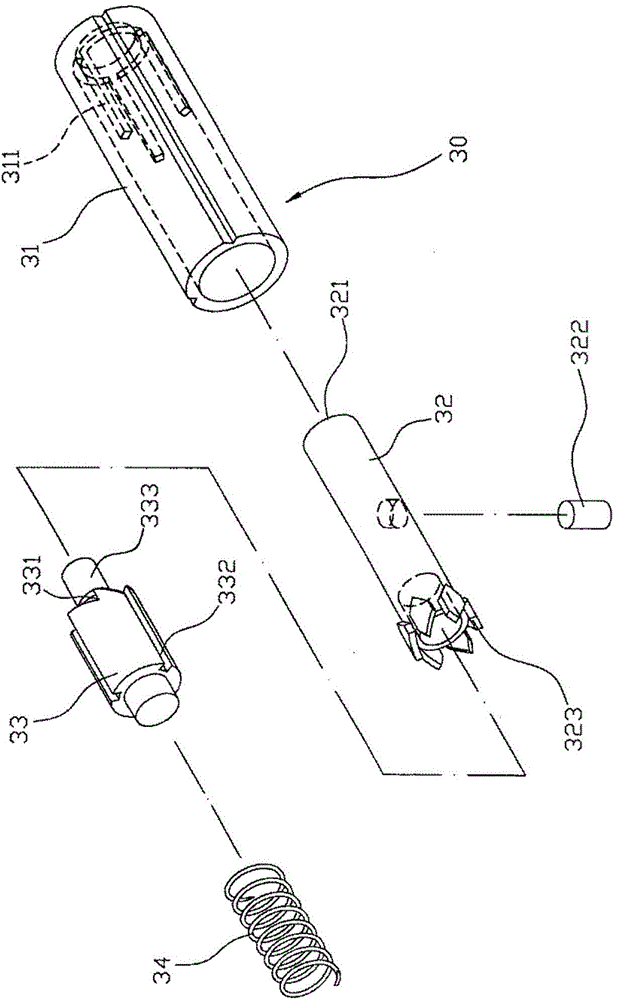

[0036] First, please see figure 1 , 2 Cooperate image 3 , 4As shown, a curtain retracting stroke control structure, which includes: a curtain body 10, an assembly 20, a catch 30, a toggle unit 40 and a shaft sleeve 50, a curtain body 10 has a Shaft tube 11, and the curtain piece 12 is rolled by the shaft tube 11, and a combination part 20 has a combination part 21, and the center of the combination part 21 extends a combined convex column 22, and is assembled eccentrically on one side of the combined convex column 22. There is a catch 30, wherein the combination part 21 of the assembly 20 is in the shape of a cylinder, and the combination part 21 is eccentrically provided with a combination container 211 to provide the assembly of the catch 30, and the combination boss 22 faces the combination container. The end surface of the groove 211 forms a dodging arc surface 221, and the outer end of the assembly 20 has a non-cylindrical combined convex portion 23, which is embedde...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap