Optical lens, camera module and electronic equipment

An optical lens and lens technology, applied in optics, optical components, instruments, etc., can solve the problems of optical lens production, increased manufacturing difficulty, high optical lens manufacturing cost, and increased assembly difficulty, so as to control manufacturing cost and reduce structural assembly Difficulty and improvement of assembly yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

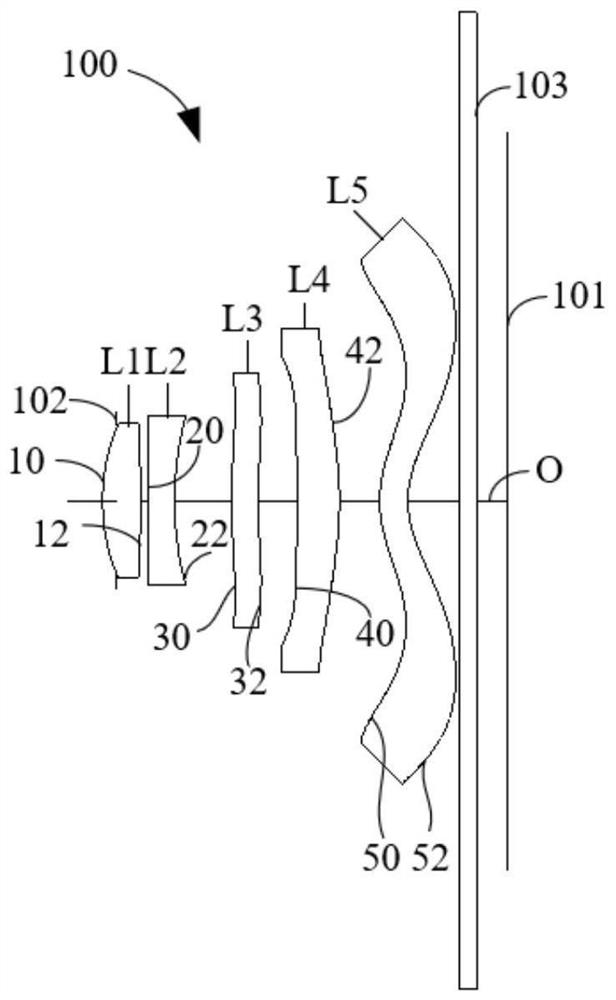

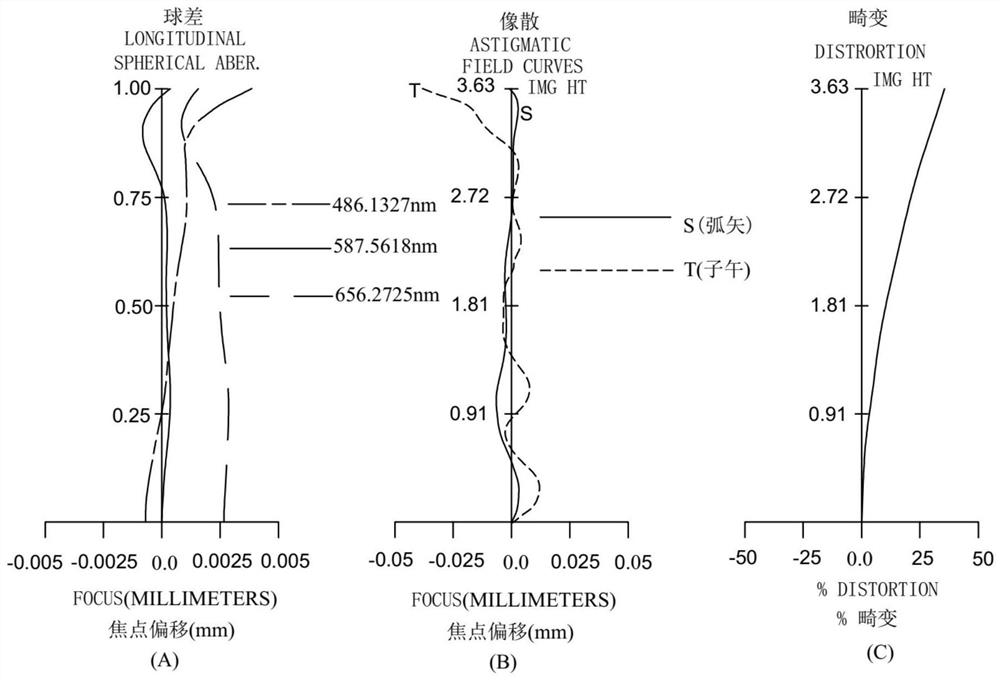

[0088] The structural schematic diagram of the optical lens 100 disclosed in Embodiment 1 of the present application is as follows figure 1 As shown, the optical lens 100 includes a diaphragm 102, a first lens L1, a second lens L2, a third lens L3, a fourth lens L4, a fifth lens L5, an infrared Filter 103 and imaging surface 101.

[0089] Among them, the focal power distribution of the above-mentioned five-piece lens is shown in Table 1 below:

[0090] Table 1

[0091] Lens Code L1 L2 L3 L4 L5 Optical power distribution just burden just just burden

[0092] Further, the object side 10 and the image side 12 of the first lens L1 are convex at the near optical axis, the object side 20 of the second lens L2 is convex at the near optical axis, and the image side 22 of the second lens L2 is at the near optical axis. The optical axis is concave. The object side 30 of the third lens L3 is convex at the near optical axis, the image side 32 of the t...

Embodiment 2

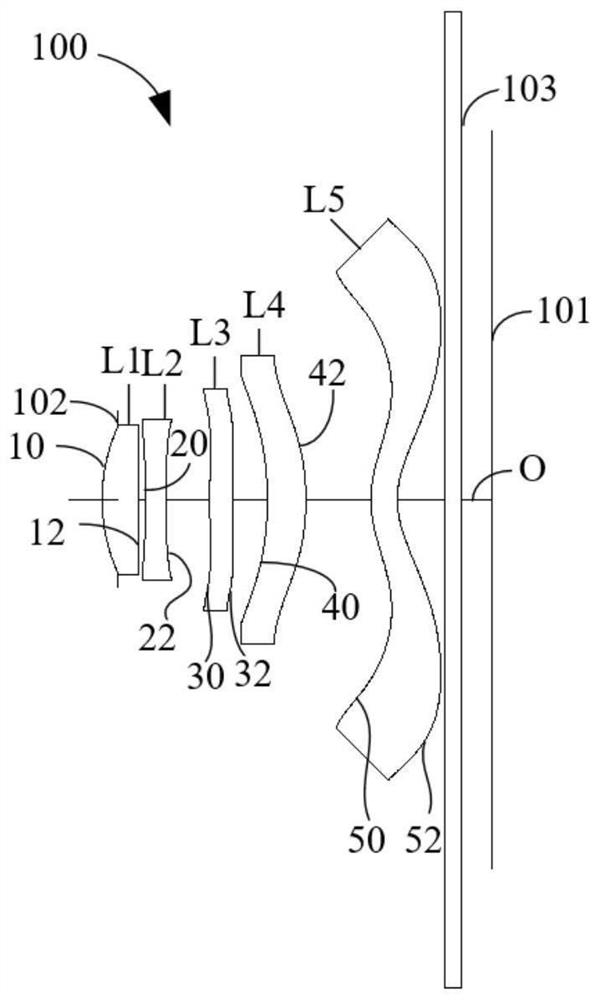

[0109] Please refer to image 3 , image 3 It is a schematic structural diagram of the optical lens 100 according to Embodiment 2 of the present application. The optical lens 100 includes a diaphragm 102, a first lens L1, a second lens L2, a third lens L3, a fourth lens L4, a fifth lens L5, and an infrared filter arranged in sequence from the object side to the image side along the optical axis O. 103 and imaging surface 101.

[0110] Among them, the focal power distribution of the above-mentioned five-piece lens is shown in Table 4 below:

[0111] Table 4

[0112]

[0113]

[0114] Further, the object side 10 and the image side 12 of the first lens L1 are convex at the near optical axis, the object side 20 of the second lens L2 is concave at the near optical axis, and the image side 22 of the second lens L2 is at the near optical axis. The optical axis is concave. The object side 30 of the third lens L3 is convex at the near optical axis, the image side 32 of the t...

Embodiment 3

[0125] Please refer to Figure 5 , Figure 5 A schematic structural diagram of the optical lens 100 according to Embodiment 3 of the present application is shown. The optical lens 100 includes a diaphragm 102, a first lens L1, a second lens L2, a third lens L3, a fourth lens L4, a fifth lens L5, and an infrared filter arranged in sequence from the object side to the image side along the optical axis O. 103 and imaging surface 101.

[0126] Among them, the focal power distribution of the above-mentioned five-piece lens is shown in Table 7 below:

[0127] Table 7

[0128] Lens Code L1 L2 L3 L4 L5 Optical power distribution just burden burden just burden

[0129] Further, the object side 10 and the image side 12 of the first lens L1 are convex at the near optical axis, the object side 20 of the second lens L2 is concave at the near optical axis, and the image side 22 of the second lens L2 is at the near optical axis. The optical axis is conc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap