Scraper plate assembly for electrolysis, scraper plate mechanism and electrolytic tank powder scraping device

A technology of scraper and components, which is applied in the field of powder scraping in electrolytic cells, can solve the problems of difficult processing, high manufacturing cost, and easy thread jamming, and achieve the effects of simple and effective structure, control of manufacturing cost, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

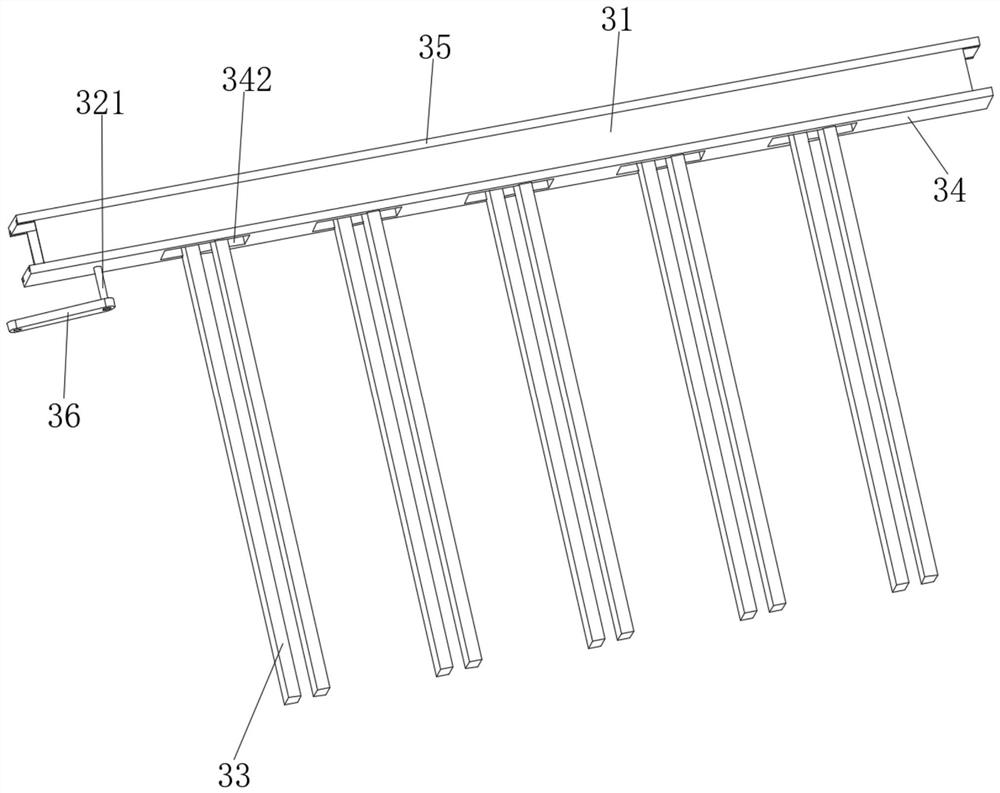

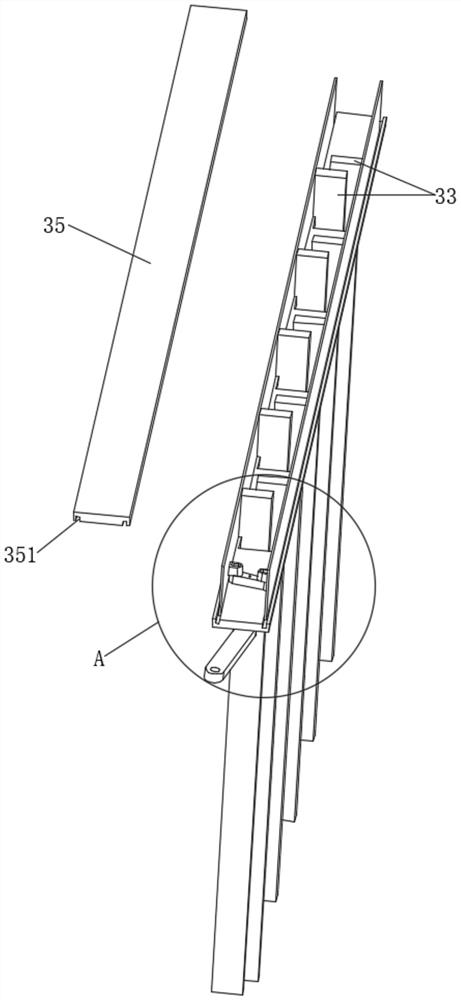

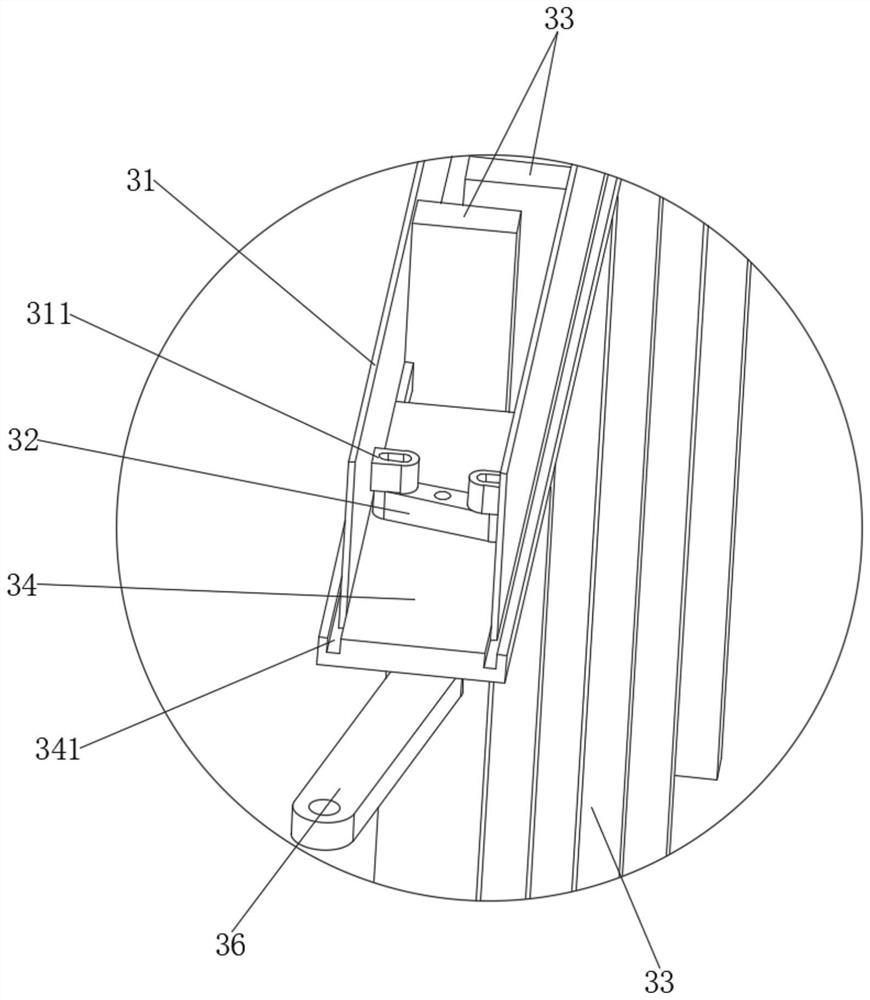

[0021] as attached Figure 1-5 As shown, the present invention provides a scraper assembly, comprising a connecting arm 32 and two moving plates 31, the two moving plates 31 are arranged in parallel, one end of the connecting arm 32 is hinged with one of the moving plates 31, and the other end moves with the other The plates 31 are hinged, two moving plates 31 are respectively connected with scrapers 33 , and a single moving plate 31 is connected with at least one scraper 33 . The connecting arm 32 can rotate around its middle. When the connecting arm 32 rotates around its middle, the two moving plates 31 move along its own length direction, and the two moving plates 31 move in opposite directions, so that the two moving plates 31 move in opposite directions. The scrapers 33 on the plate 31 are moved closer to or away from each other, so that the distance between the two scrapers 33 is adjusted. Among them, such as figure 2 and 3 As shown, the scrapers 33 are located betwe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap