Pump for pumping a liquid

A technology for conveying liquids and liquids, which is applied in the field of exhaust pipeline devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

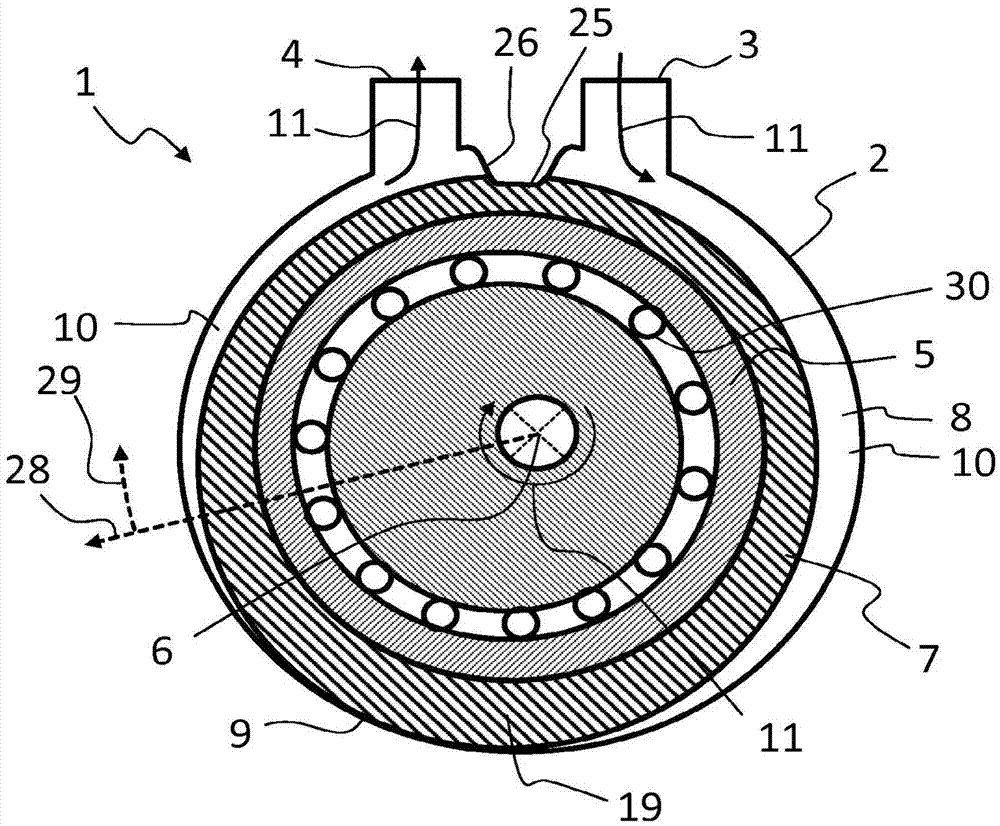

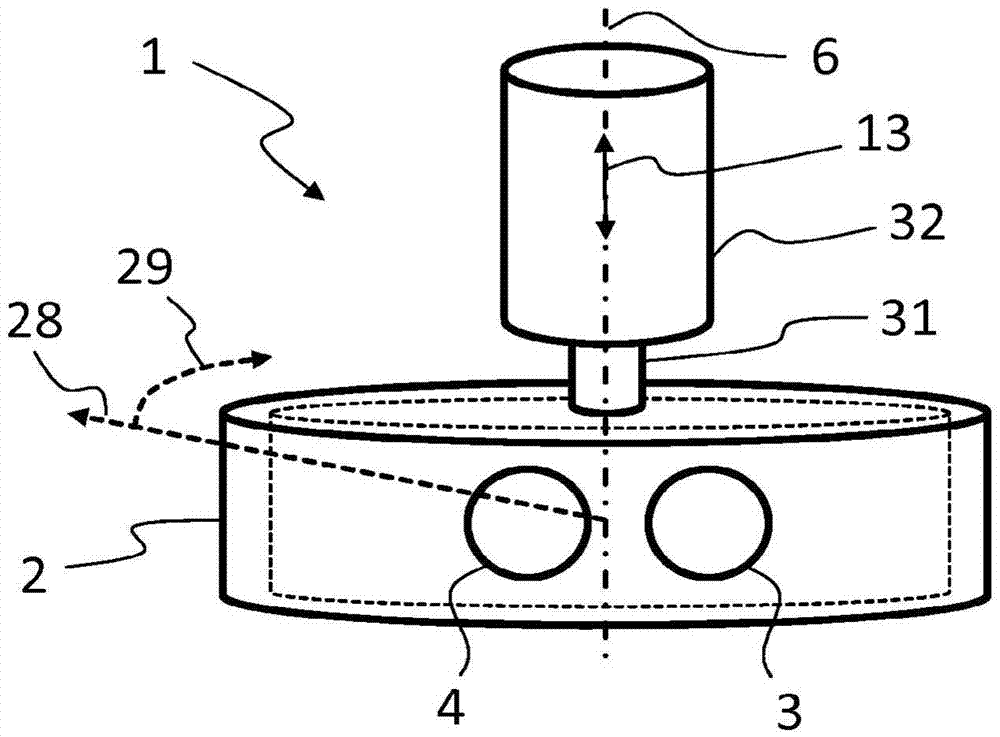

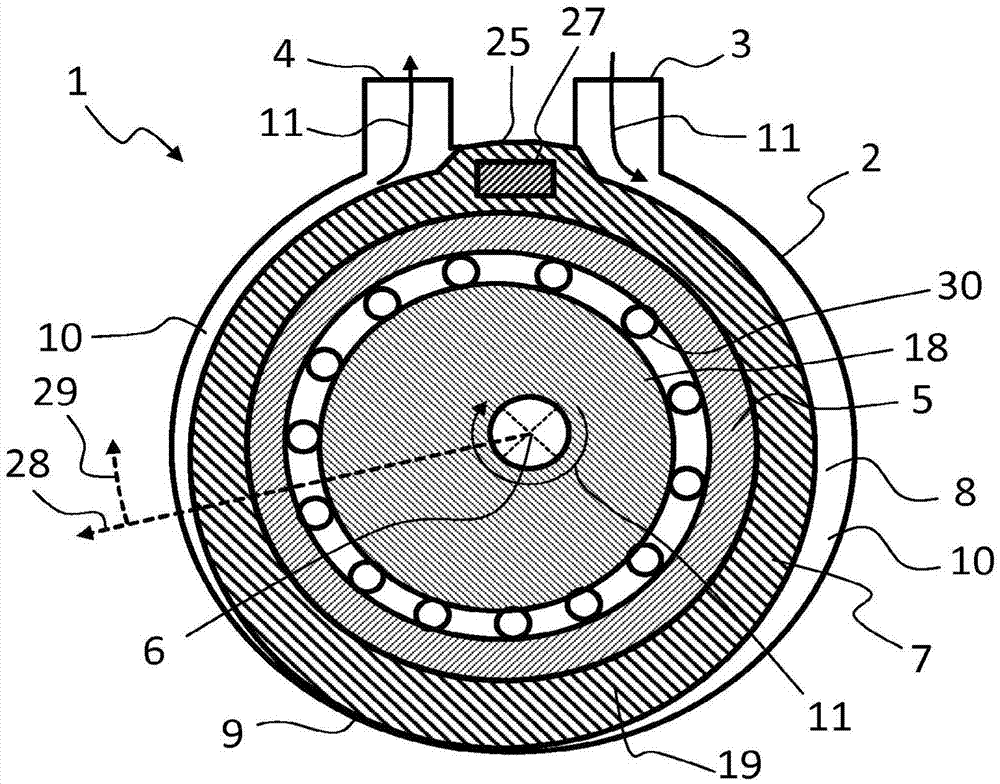

[0064] figure 1 with image 3 Two different specific embodiments of the pump 1 are shown, each having a deformable membrane 19 as deformable element 7 . To illustrate the pump, the figure 1 with 3 A coordinate system with axis 6 , radial direction 28 and circumferential direction 29 is shown in .

[0065] The deformable element 7 is arranged in the pump housing 2 between the pump housing 2 and the eccentric 5 . The pump housing 2 has an inlet 3 through which liquid can flow into the pump housing 2 in a conveying direction 11 , and an outlet 4 through which liquid can flow out of the pump housing 2 in a conveying direction 11 . The eccentric 5 is arranged rotatably about an axis 6 in the pump housing 2 . When the eccentric 5 rotates, the rotation of the eccentric 5 is converted via the bearing 30 into a rolling motion of the deformable element 7 on the pump housing 2 . As a result, the deformable element 7 locally abuts against the pump housing 2 and forms a seal 9 . Bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com