Automatic tea rolling machine

A technology for rolling machines and tea leaves, which is applied in the field of automatic tea rolling machines for tea, can solve the problems of low efficiency, high labor intensity of operators, inability to realize automatic production, etc., and achieve the effects of ensuring rolling quality, reducing manual participation and improving operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

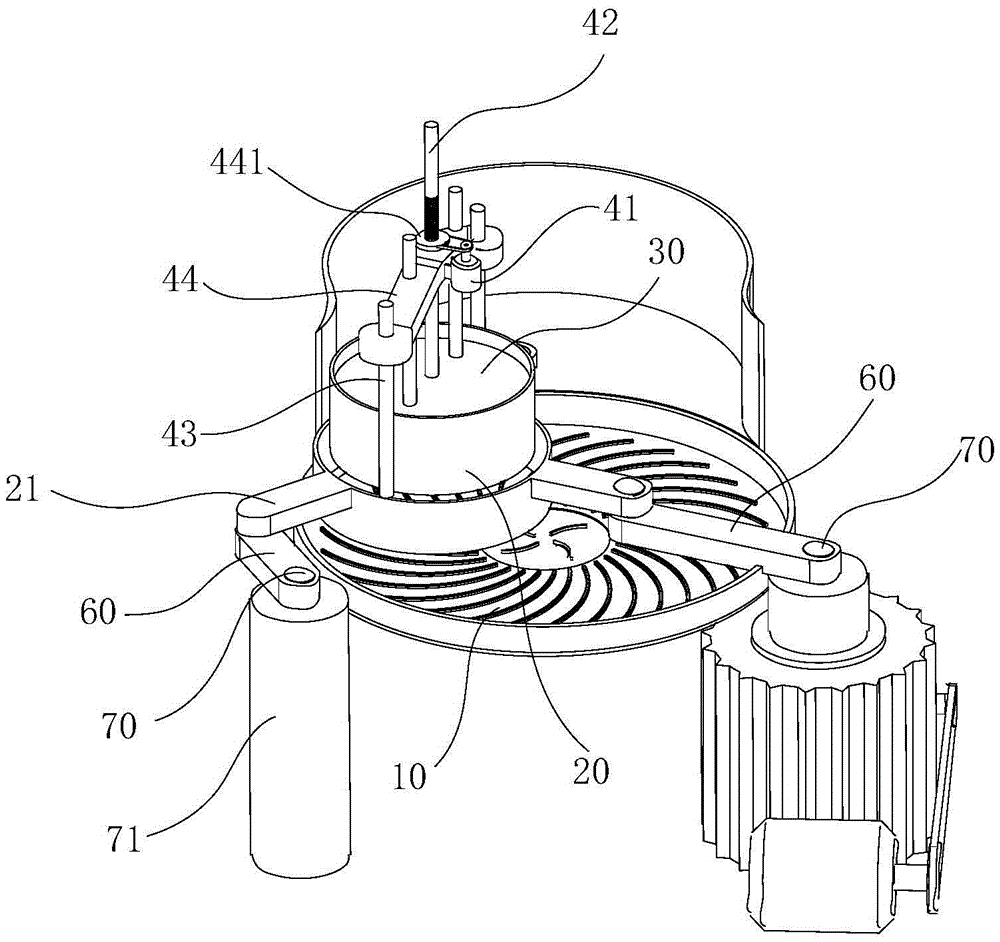

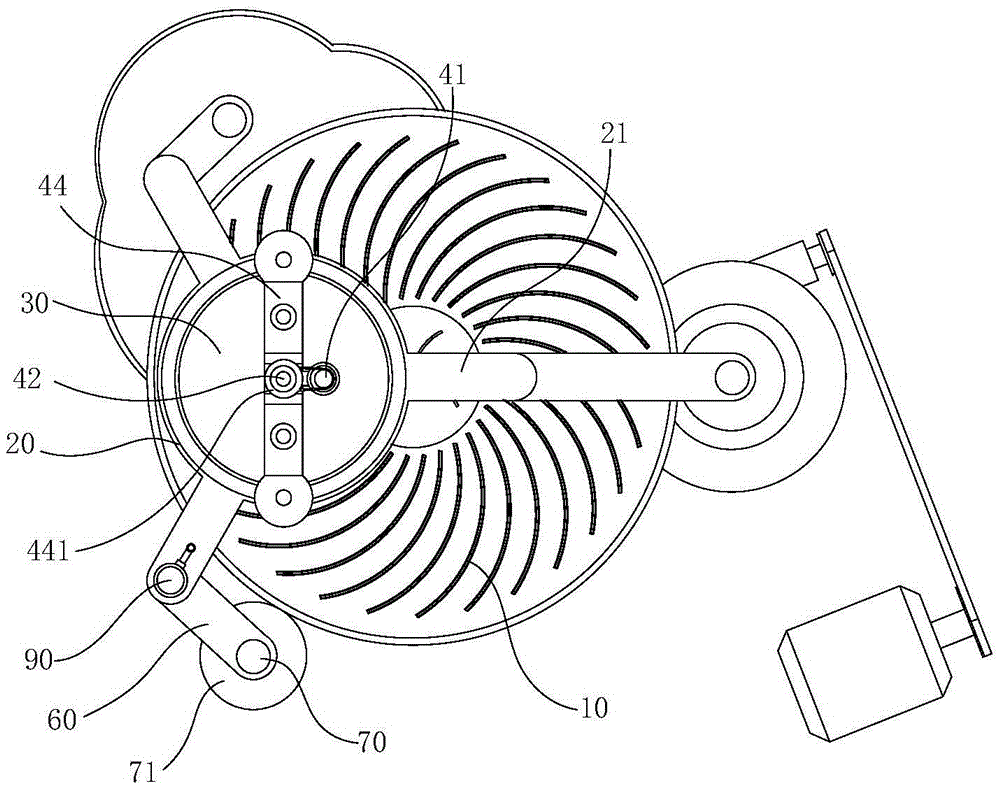

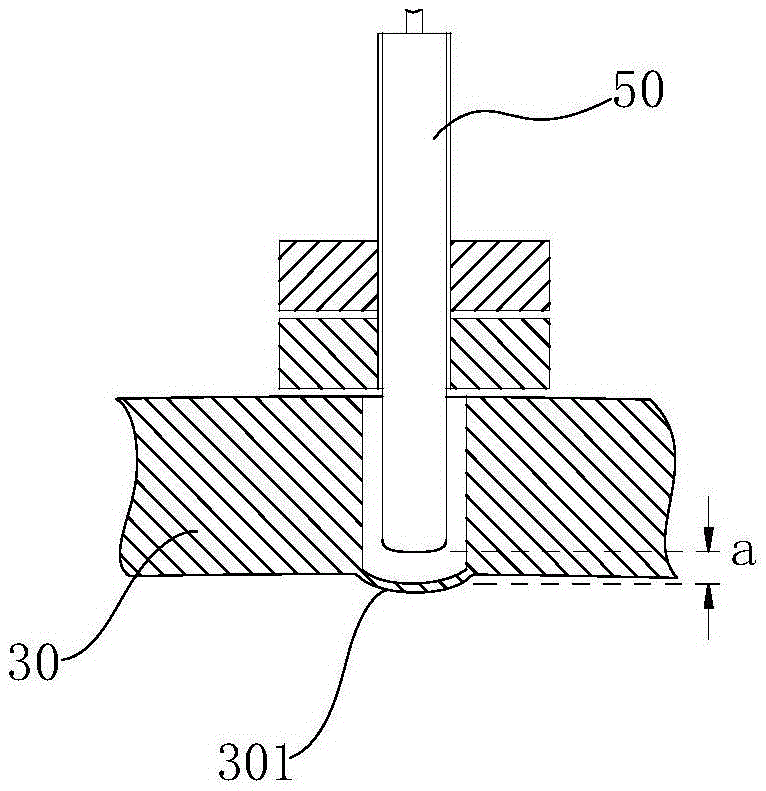

[0011] Combine Figure 1 to Figure 4 , To further explain the present invention in detail:

[0012] An automated tea kneading machine, comprising a kneading plate 10, a vertically arranged kneading drum 20 is arranged above the surface of the kneading plate 10, and a pressing cover 30 is arranged on the kneading drum 20, and the pressing cover 30 is connected with a lifting mechanism. The lifting mechanism includes a motor 41. The pressing cover 30 is connected to the lower end of the tie rod 42. A transmission mechanism is arranged between the tie rod 42 and the motor 41. The motor 41 drives the tie rod 42 through the transmission mechanism to lift and move and link the pressing cover 30 and the twisting disc 10 When the upper plate surface is close to or far away, the rolling machine is also provided with a rolling motor 11, and the rolling motor 11 drives the rolling drum 20 to rotate and implement the rolling operation.

[0013] The kneading motor 11 drives the kneading drum 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com