Glass wiping tool

A glass and tool technology, applied in the field of glass wiping tools, can solve the problems of reduced work efficiency, inconvenient wiping, waste of dust-free cloth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

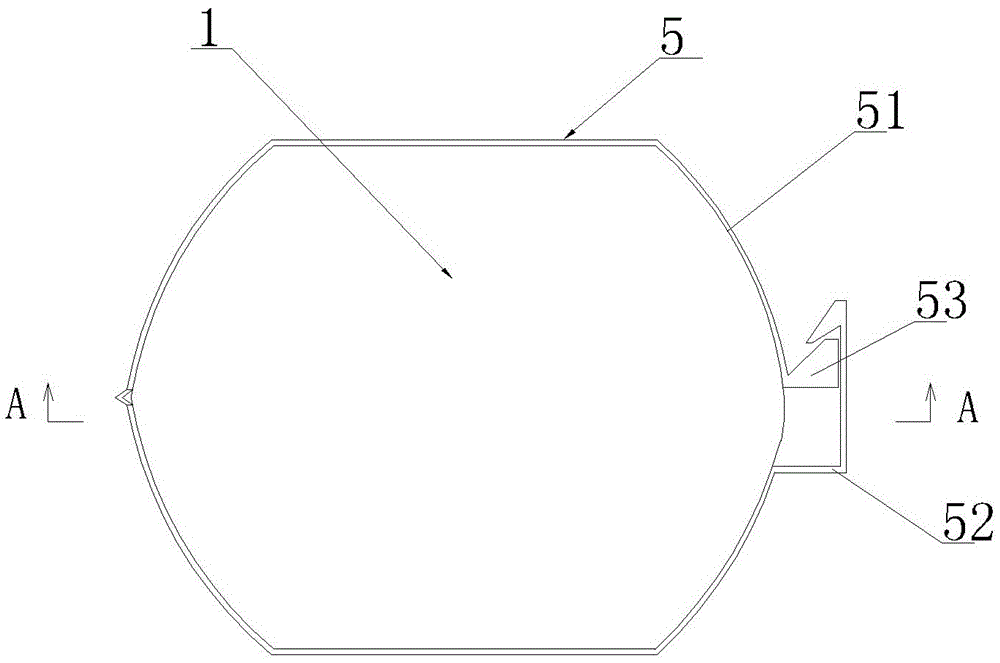

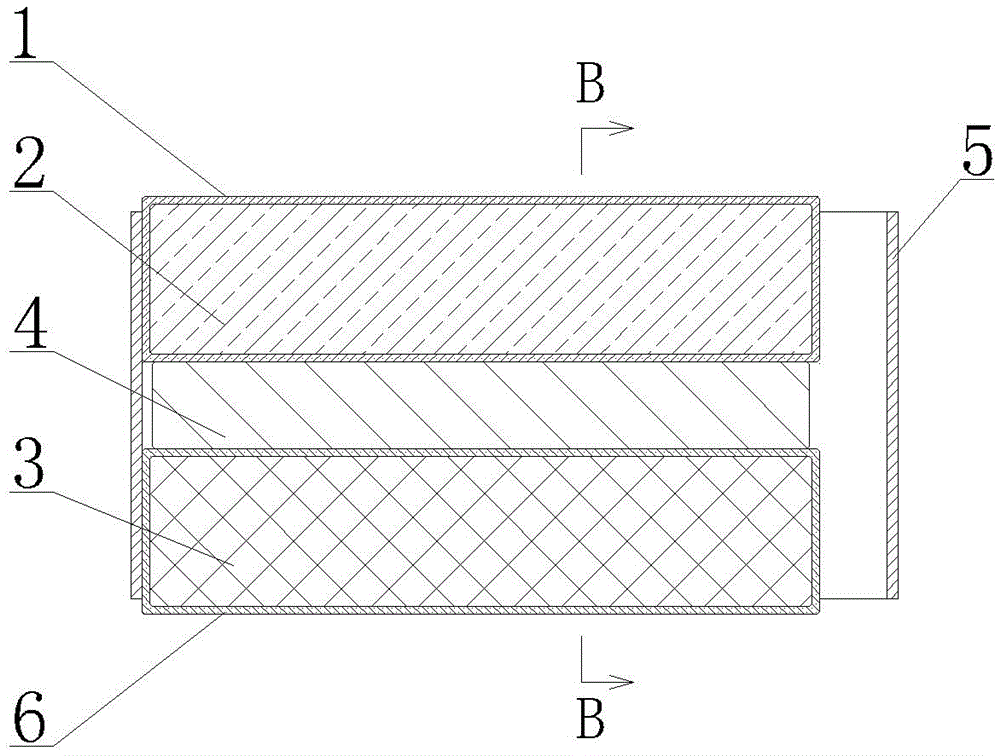

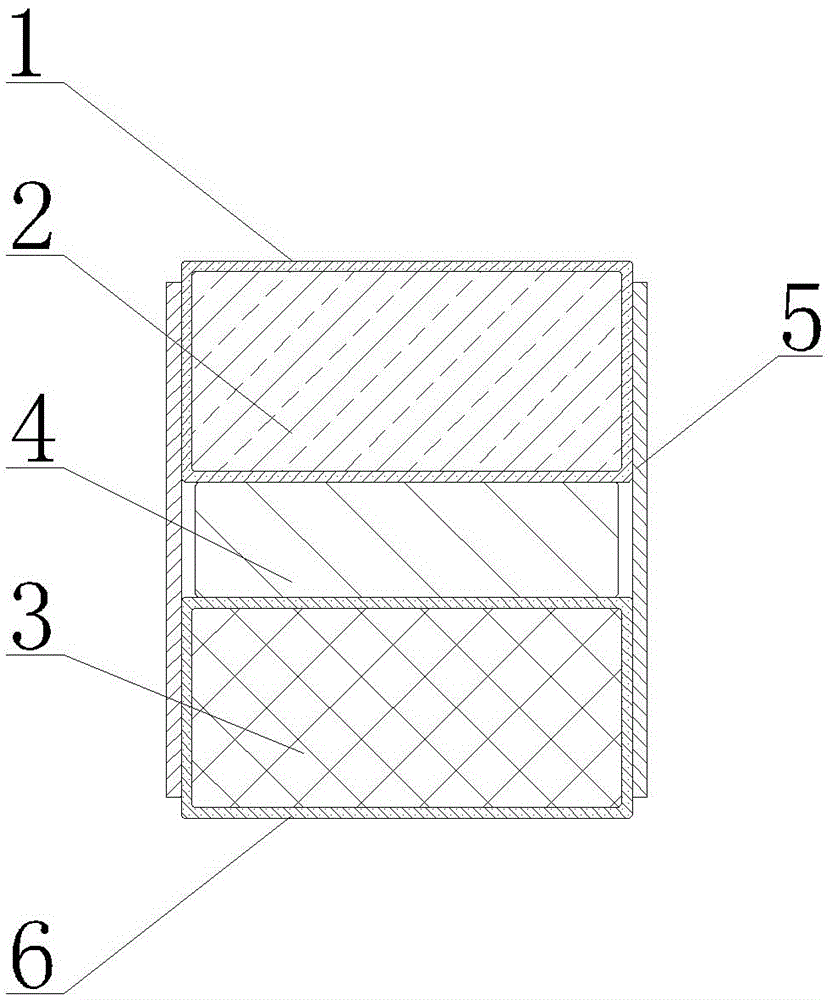

[0015] Such as figure 1 , figure 2 As shown, the glass wiping tool of the present invention includes: two dust-free cloths, namely: the first dust-free cloth 1 and the second dust-free cloth 6, wherein the first dust-free cloth 1 is wrapped on the sponge board 2, And the closing of the first dust-free cloth 1 sticks on one side of the sponge board 2, the second dust-free cloth 6 is wrapped on the foam board 3, and the closing of the second dust-free cloth 6 sticks on one side of the foam board 3 , the shape and size of the sponge board 2 and the foam board 3 are the same, specifically: the middle is a cuboid, and the two ends of the cuboid are provided with outwardly protruding arc-shaped arc-shaped boards. A plastic partition 4 is arranged in the middle of the sponge board 2 and the foam board 3, and the side wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com