A Welding Production Process of R4 Anchor Chain

A production process and anchor chain technology, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of large deformation of anchor chain rings, unsatisfactory welding section size, low flash welding efficiency, etc., and reduce stress concentration. , The effect of reducing the upsetting distance and accelerating the melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

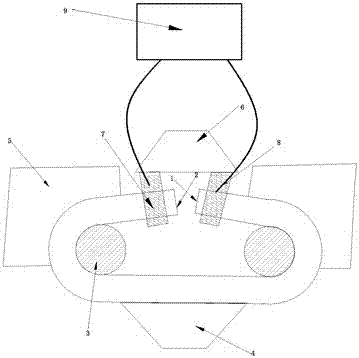

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] The steps of the process are as follows:

[0026] Step one, unloading. For marine engineering equipment, a greater mooring effect is required, and there are high requirements for the strength and toughness of the anchor chain; while the ocean is a corrosive environment, the anchor chain also needs to have better corrosion resistance. It is required that the anchor chain choose high-strength steel with the required performance of R4 anchor chain as the round steel material, and the round steel contains the following components in terms of mass percentage: C: 0.16-0.18%, Si: 0.42-0.50%, Mn: 0.8- 1.0%, Cr: 0.42-0.70%, Mo: 0.20-0.36%, Al: 0.03-0.04%, S: ≤0.02%, P: ≤0.02%, the balance is Fe; yield strength ≥ 680MPa, tensile strength ≥ 860MPa, elongation ≥ 14%, reduction of area ≥ 50%, and the diameter of the formed round steel is 100mm-126mm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com