Production process of welded anchor chain

A production process and anchor chain technology, which is applied to ships and other directions, can solve the problems of low efficiency of flash welding, non-conformity of welding section size, large deformation of anchor chain rings, etc., to reduce upsetting distance, control end face misalignment, and reduce stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

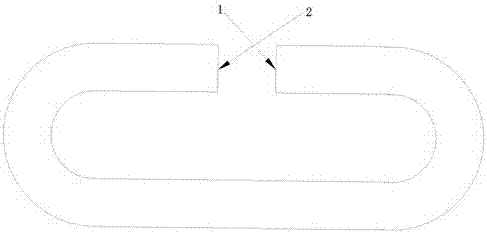

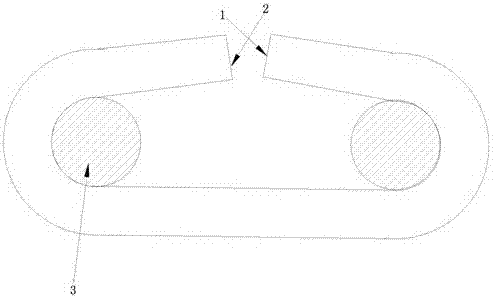

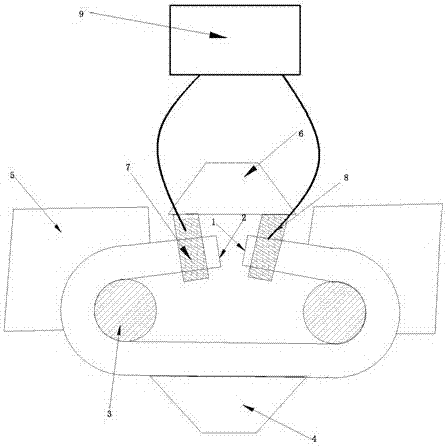

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] The steps of the process are as follows:

[0025] Step one, prepare materials. For marine engineering equipment, a greater mooring effect is required, and there are high requirements for the strength and toughness of the anchor chain; while the ocean is a corrosive environment, the anchor chain also needs to have better corrosion resistance. Requirements, the anchor chain chooses the killed steel that meets the performance required by the third-grade anchor chain as the round steel material, which contains the following components in terms of mass percentage: C: 0.28-0.32%, Si: 0.68-2.46%, Mn: 0.8-1.1% , Cr: 0.42-0.75%, V: 0.06-0.14%, Ti: 0.01-0.03%, S: ≤0.02%, P: ≤0.02%, the rest is Fe; mechanical properties and material properties are: yield strength ≥ 620MPa, Tensile strength ≥ 780MPa, elongation ≥ 17%, reduction of area ≥ 40%, and the diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com