Pneumatic tires

A technology of pneumatic tires and treads, applied in tire parts, tire treads/tread patterns, transportation and packaging, etc., can solve the problem of braking performance on ice and steering performance degradation on ice, ground contact degradation, edge effect It can improve the braking performance and steering performance on ice, suppress the frictional contact deformation, and improve the edge effect.

Active Publication Date: 2016-04-06

TOYO TIRE & RUBBER CO LTD

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, in the inner side of the tread rubber in the tire width direction, that is, in the central region, due to such three-dimensional sipes, the rigidity of the tread rubber becomes too high, so the ground contact performance is reduced.

Specifically, the uniformity of the ground contact pressure of the block decreases, and the contact area of the block also becomes smaller

As a result, the edge effect is also reduced, so braking performance on ice and steering performance on ice are reduced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~5

[0092] Example 1 is the tire of the above-mentioned embodiment.

[0093] Example 2 is a tire changed from the tire of Example 1 to L1c:L2c=40%:60%.

[0094] Example 3 is a tire changed from the tire of Example 1 to L1c:L2c=0%:100%.

[0095] Example 4 is a tire changed from the tire of Example 1 to L1s:L2s=70%:30%.

[0096] Example 5 is a tire changed from the tire of Example 1 to L1s:L2s=100%:0%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

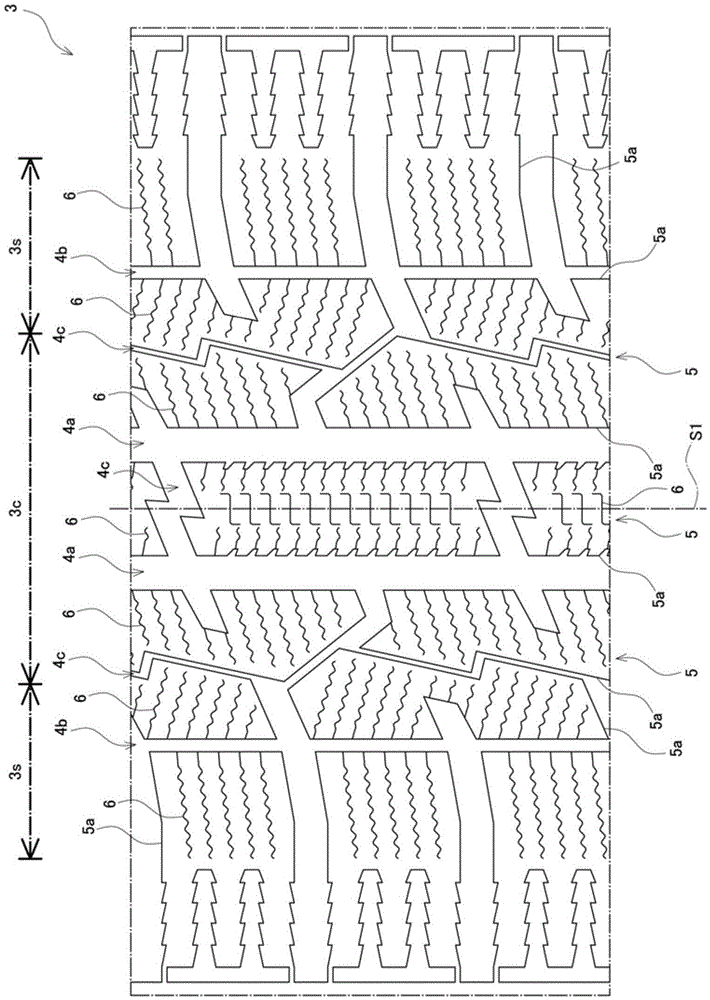

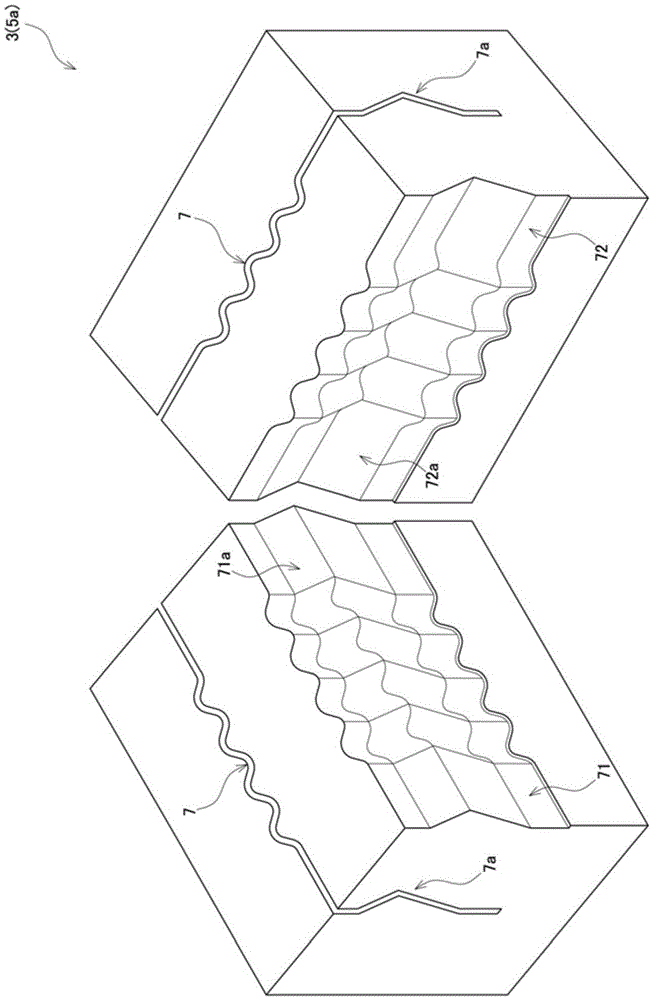

In a pneumatic tire 1, the first three-dimensional lamellae 7 are provided with bent portions 7a which are bended upwardly a depth direction of the sipe, and are formed to have a constant sipe width W11-W14 along a depth direction of the sipe, wherein the second three-dimensional blades 8 with width proportions 8a-8c equipped which 3 a wider slat width W22-W24 have in an inner portion of the tread rubber, as a slat width W21 of a surface of the tread rubber 3 ,; wherein in a shoulder portion 3s of the tread rubber 3, an amount of the surface length L1s of the first three-dimensional lamellae 7 is longer than an amount of the surface length L2s of the second three-dimensional lamellae 8 and an amount of surface length L2c the second three-dimensional sipes 8 is at a central portion 3c of the tread rubber longer than an amount of surface length L1c the first three-dimensional sipes.

Description

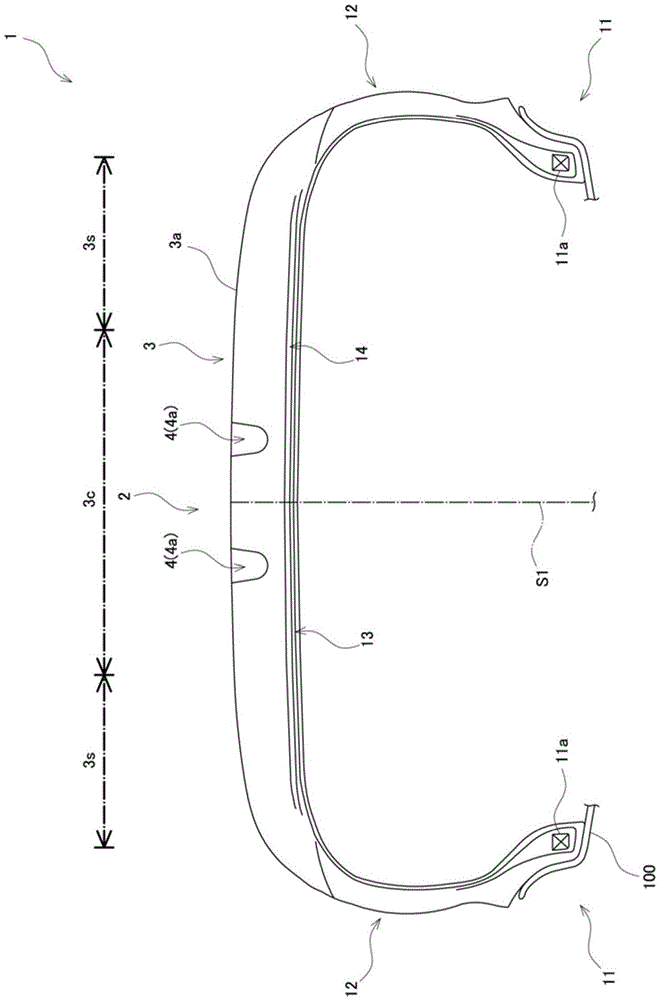

technical field [0001] The present invention relates to a pneumatic tire having a plurality of three-dimensional sipes on tread rubber. Background technique [0002] In a pneumatic tire, when the tread rubber comes into contact with the road surface, the curved surface is deformed into a flat surface. As a result, a force (also referred to as "in-plane contraction force") acts from one end in the tire width direction, that is, the shoulder side, toward the tire width direction center, that is, the center side, on the ground contact surface in contact with the road surface, so that the tread rubber Deformation in the tire width direction. Such deformation (also referred to as "wiping deformation") occurs over the entire ground contact surface, but is particularly large in the outer side in the tire width direction, that is, in the shoulder region. [0003] Therefore, there is known a pneumatic tire having a plurality of three-dimensional sipes on the tread rubber (for examp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B60C11/03

CPCB60C11/1218B60C2011/1213B60C2011/1227

Inventor 谷口二朗

Owner TOYO TIRE & RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com