Lifting mechanism for nut shell packaging

A technology for nut shells and nuts, which is applied in the field of nut shell packaging and lifting mechanisms, which can solve the problems of wasting shell value, troublesome shell removal, environmental pollution, etc., and achieves the effect of high removal efficiency and simple force application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

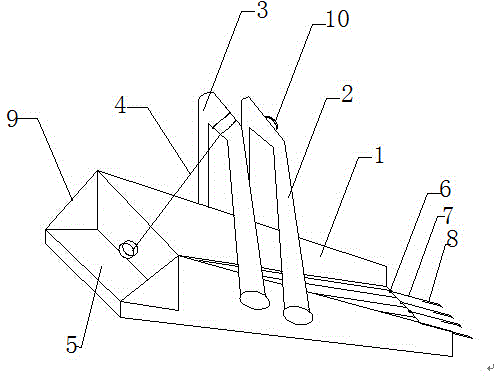

[0014] Such as figure 1 The shown a kind of nut shell packing and lifting mechanism comprises a hopper 1; the hopper 1 is dustpan-shaped; fixed handles 2 and moving handles 3 are installed on both sides of the hopper 1; the fixed handle 2 is fixed on The front side of the hopper 1; the moving handle 3 is installed on the rear side of the fixed handle 2, and is hinged with the hopper 1; an anti-tilt rope 4 is installed between the rear side of the hopper 1 and the moving handle 3; the hopper 1 An extended force applying plate 5 is arranged at the rear.

[0015] The entrance of the hopper 1 is provided with threaded through holes 6 at intervals; the threaded through holes 6 are provided with digging teeth 7 of glass fiber reinforced plastic structure.

[0016] The head 8 of the digging tooth is set in a hook shape; some husks are pulled out from the husk pile, which is beneficial to the filling of the hopper 1 next time.

[0017] A rib plate 9 is arranged between the extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com