Integrating and conveying mechanism with tracing function

A technology of conveying mechanism and function, which is applied in the field of dairy production and complete sets of dairy production automation equipment, can solve the problems of low work efficiency, time-consuming and laborious, and large labor demand, and achieve the effect of being suitable for popularization and improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

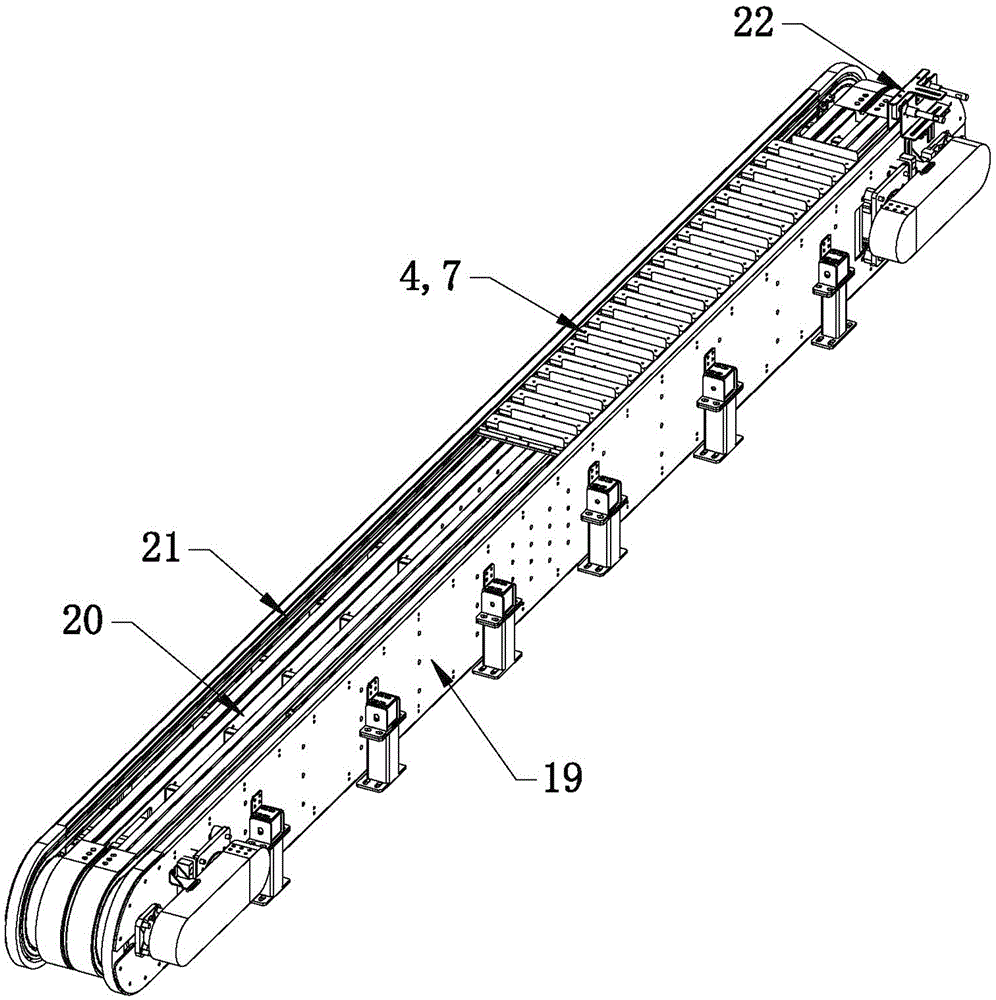

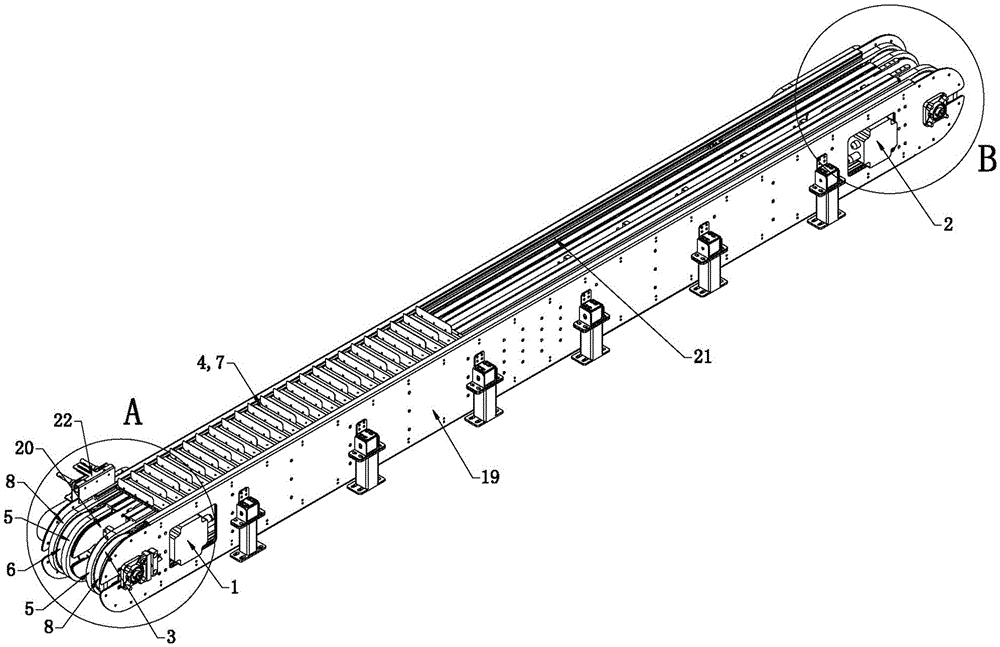

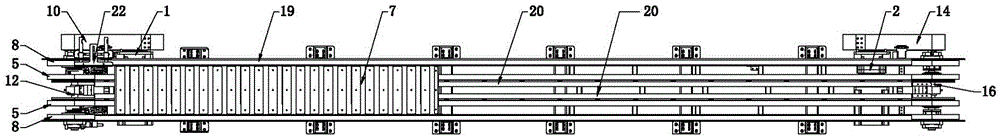

[0031] Below, one end with the material baffle plate 22 is provided with the tension servo motor 1, the tension sprocket 3 is located between the thrust sprockets 4, and the tension integrated conveyor belt 4 and the thrust integrated conveyor belt 7 are all provided with twenty material tanks. The integrated conveying mechanism of the tracking and tracking function is used to further illustrate the technical solution of the present invention.

[0032] Such as Figure 1-9 As shown, the tension servo motor 1 and the thrust servo motor 2 are respectively arranged at the two ends of the elliptical working cavity formed by two outer plates 19, wherein the driving end of the tension servo motor 1 is provided with a tension driving wheel 9, and a tension driving wheel 9 The pulling force synchronous belt 10 is connected with the pulling force driven wheel 11, and the pulling force driven wheel 11 is provided with a pulling force shaft 12, and two pulling force driving sprockets 31 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com