Auxiliary offline machine

A technology of off-line machine and driving mechanism, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of low unloading efficiency, and achieve the effect of improving unloading efficiency and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

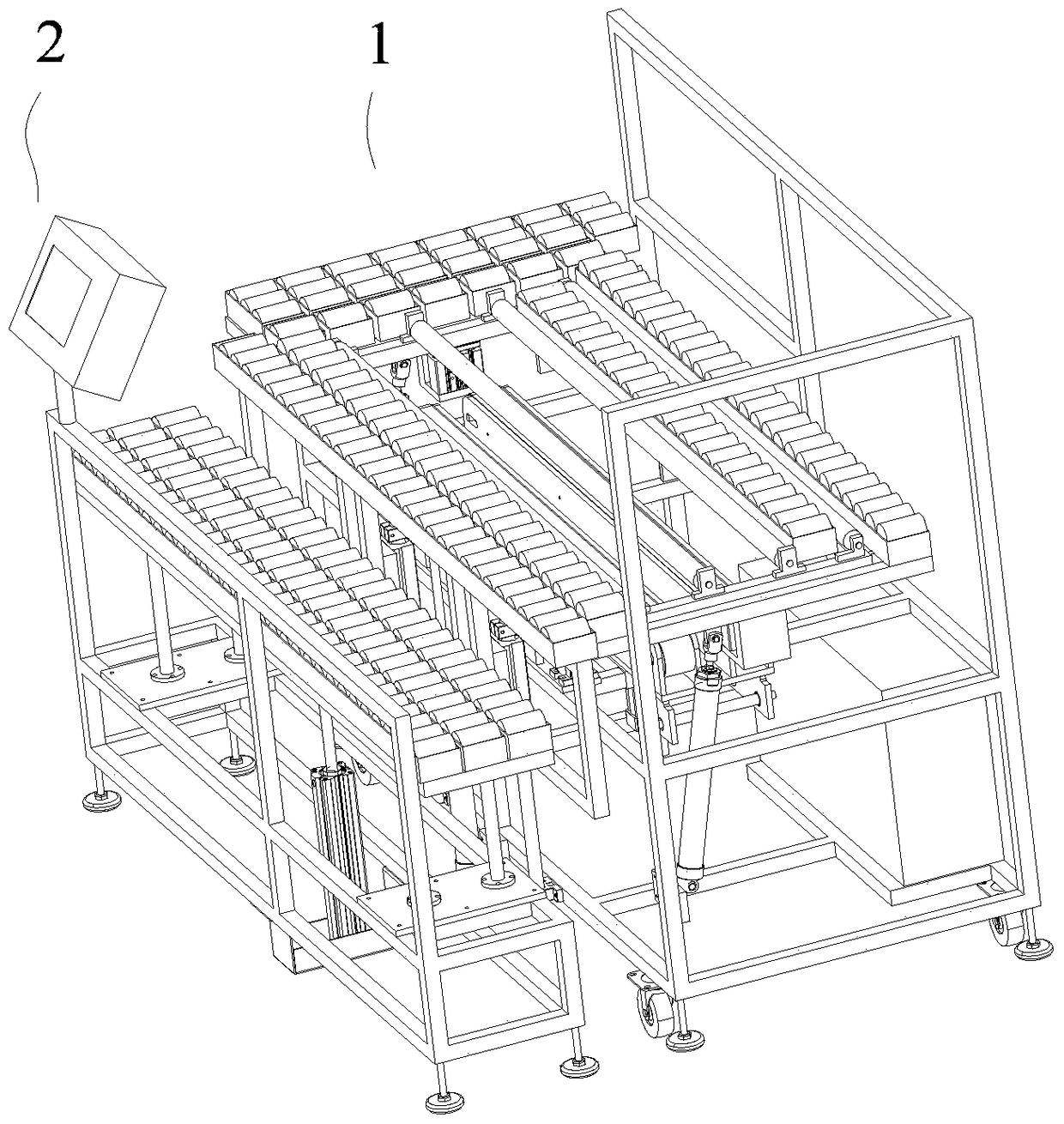

[0035] The invention provides an auxiliary off-line machine, such as figure 1 As shown, the auxiliary offline machine includes an overturning unloading device 1 and a unloading supporting device 2 .

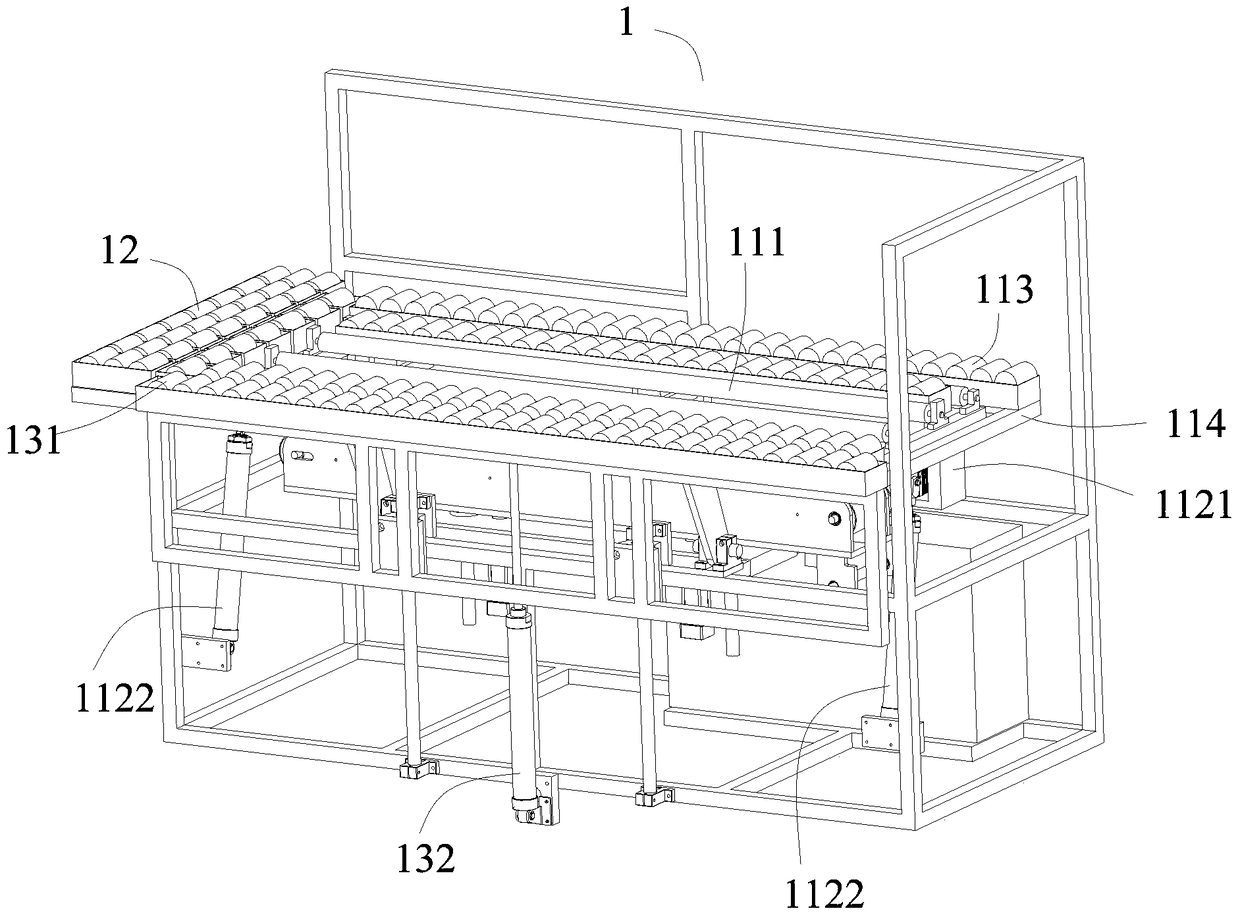

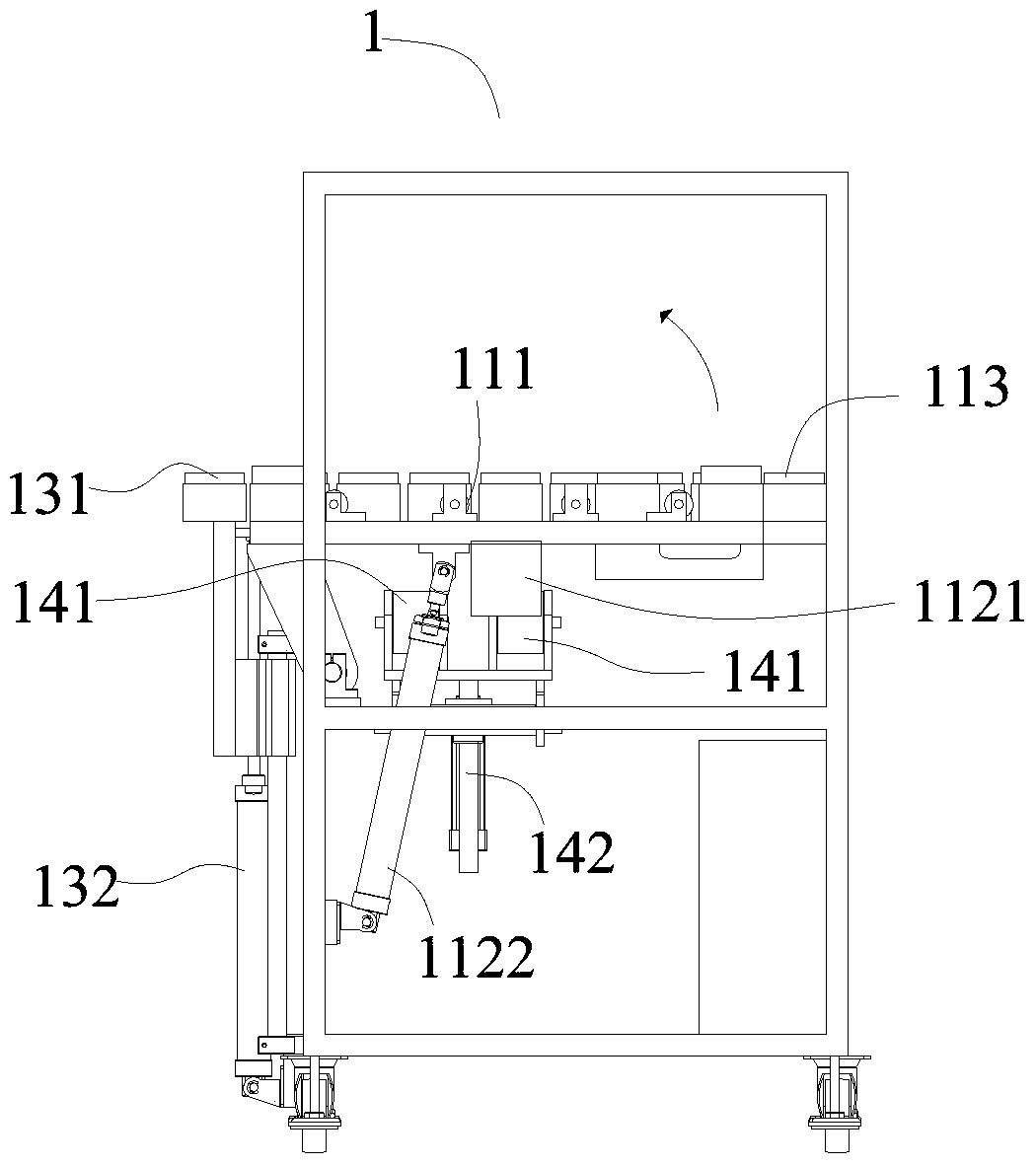

[0036] Such as Figure 2 to Figure 4 shown, where Figure 4 Some parts that have little relationship with the present invention are hidden in order to show the structure of the present invention more clearly. The turning and unloading device 1 includes a turning drive mechanism and a turning supporting roller 111, and the axial direction of the turning supporting roller 111 is consistent with the discharge The direction is perpendicular to each other, and the overturning supporting roller 111 can rotate around its roller shaft. There are more than two overturning supporting rollers 111 and they together form an overtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com