High-cold region solar cell panel with snow melting antifreeze function

A technology for solar panels and alpine regions, applied in photovoltaic power generation, electrical components, photovoltaic modules, etc., can solve the problems of reducing the service cycle and life of solar panels, difficulty in snow accumulation, and damage to the internal structure of solar panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the actual application form of the present invention is not limited to the illustrated embodiment.

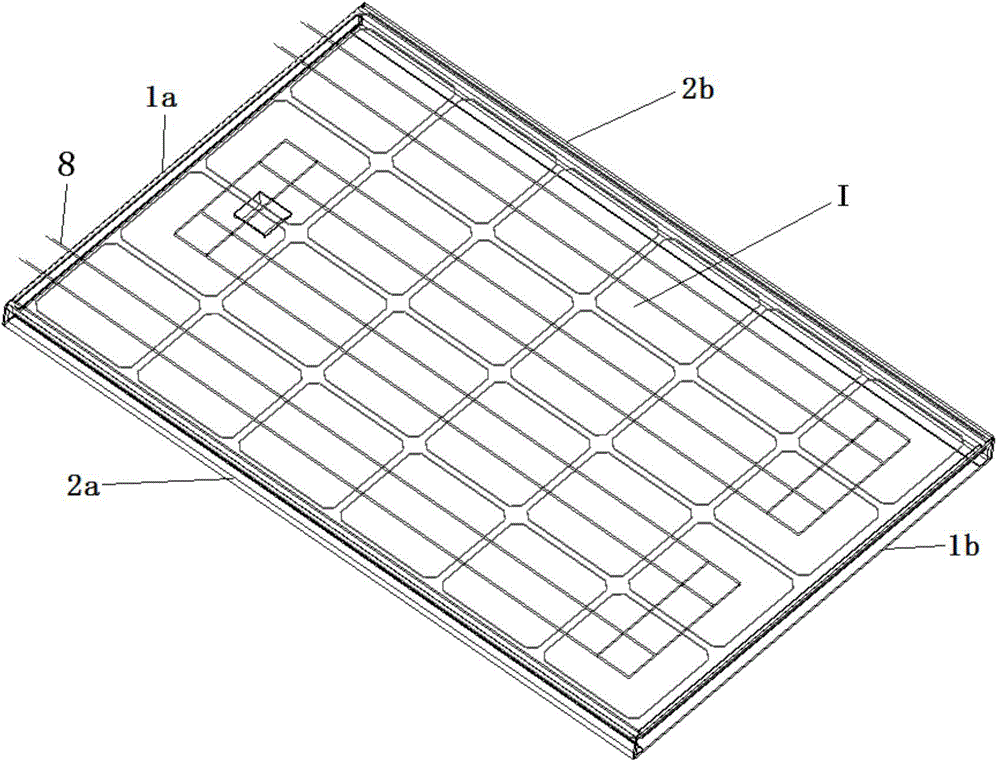

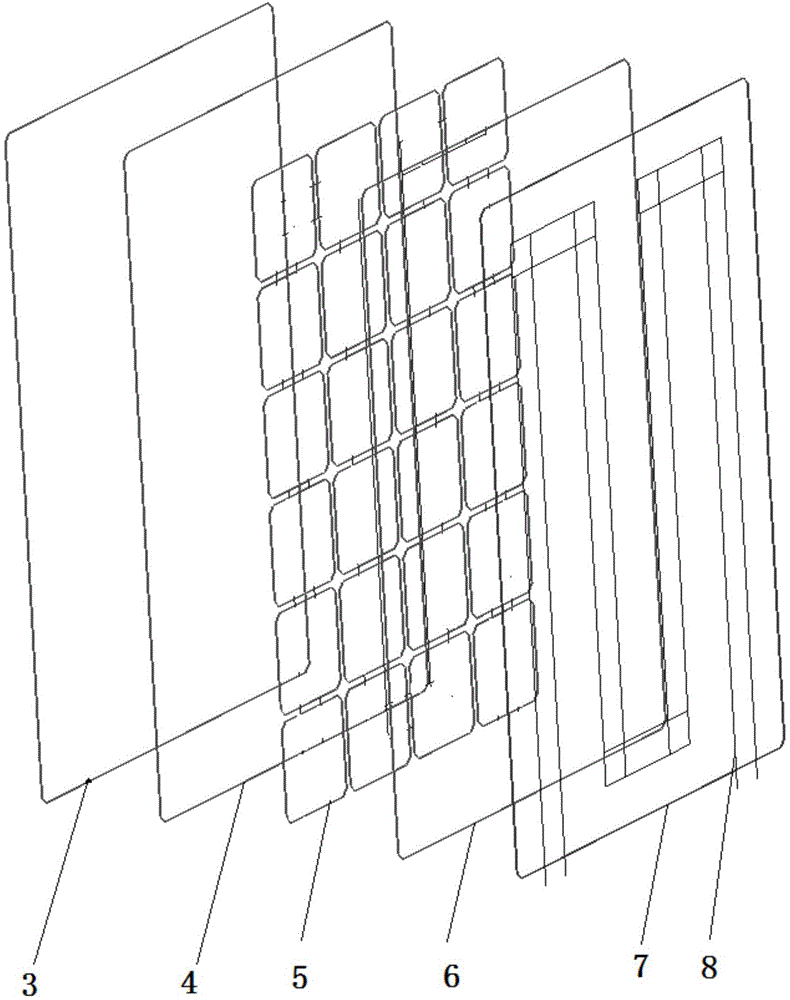

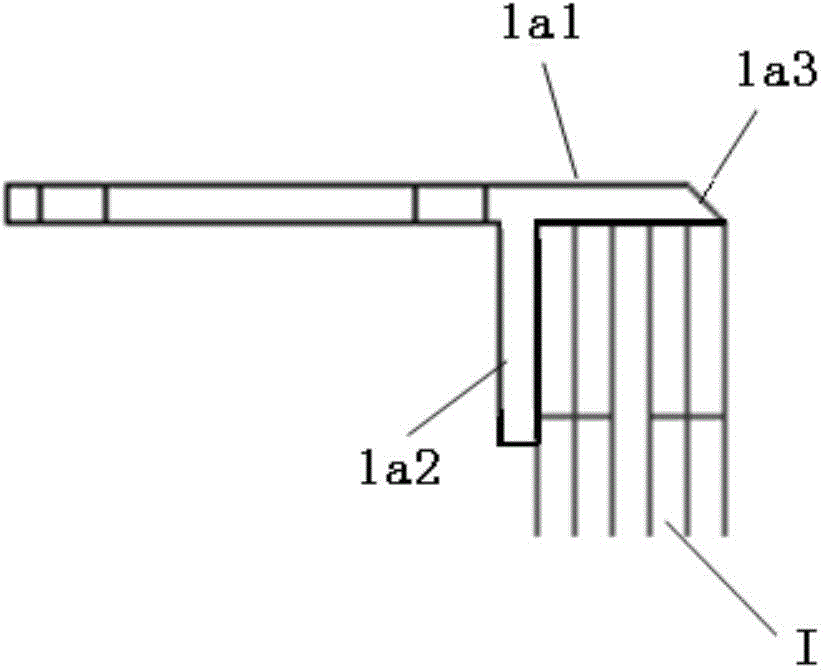

[0018] Referring to the accompanying drawings, the solar panel of the present invention includes a rectangular solar panel assembly I and a frame surrounding the solar panel assembly I, and the installation angle of the panel relative to the ground is 30°-60°. The structure of the solar panel assembly I is as follows figure 2 As shown, it consists of a glass base plate 3, a rear PVB plate 4, a solar cell 5, a front PVB plate 6 and a glass cover plate 7 which are laminated and bonded from back to front. A layer of electric heating wire 8 is screen-printed in a shape arrangement form. The frame is surrounded by upper and lower frame side profiles 1a, 1b and left and right frame side profiles 2a, 2b, wherein the structure of the upper frame side profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com