Humidification filter medium and humidification filter

A technology of wet filtration and medium, which is applied in the field of humidification filter to achieve the effect of stable humidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

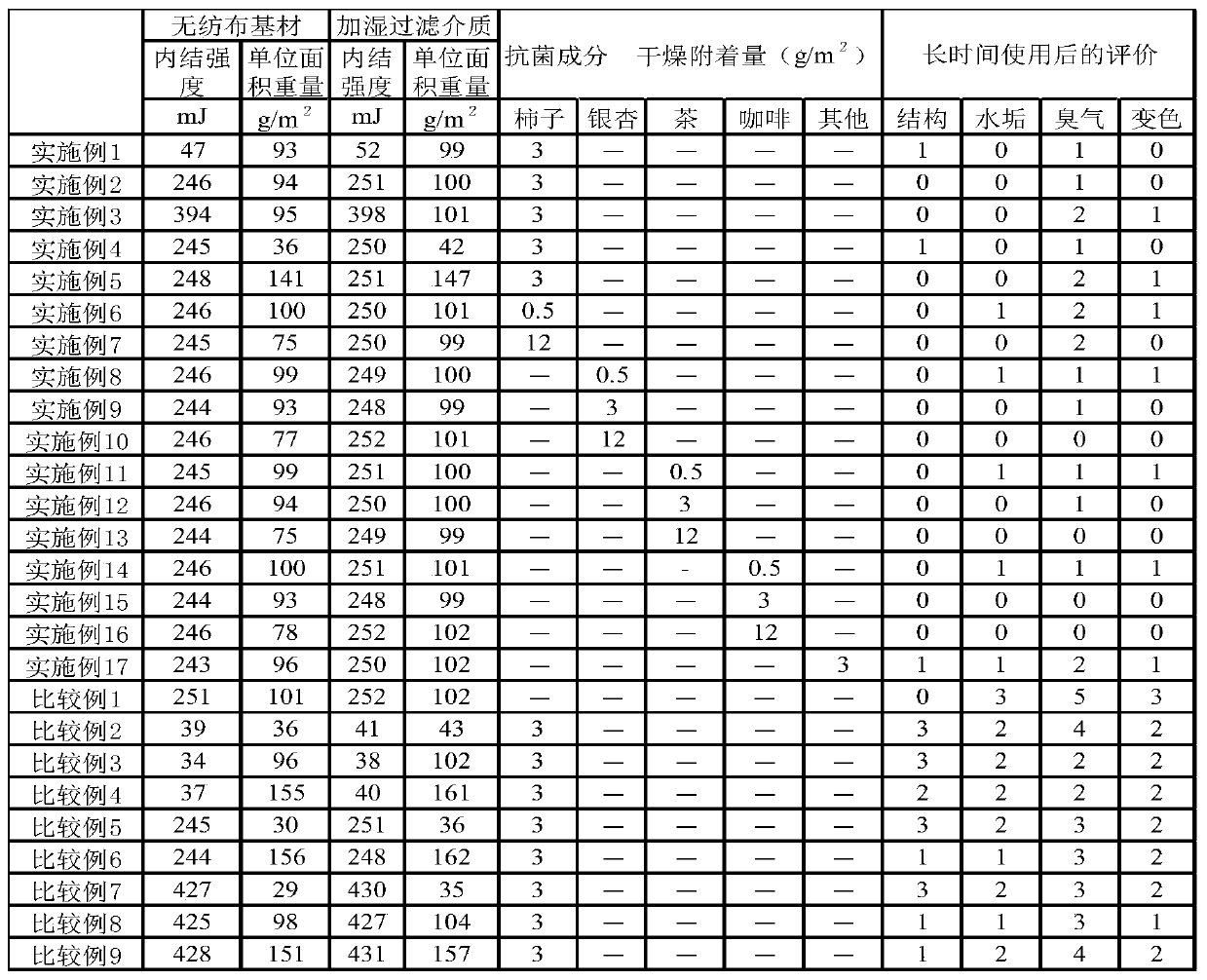

Embodiment 1

[0063] Persimmon lacquer extract and acrylic adhesive (manufactured by Japan Coating Resin Corporation, trade name: RIKABOND (registered trademark) FK-68H) were mixed in a dry mass ratio of 1:1 to obtain persimmon lacquer Extract dispersion. Then, with internal bonding strength of 47mJ and weight per unit area of 93g / m 2 Polyethylene terephthalate (PET): rayon=50:50 (dry mass ratio) spunlace non-woven fabric is used as the non-woven fabric substrate, and the non-woven fabric substrate is impregnated with this solution Processed so that the dry content of persimmon lacquer extract is 3g / m 2 . After the impregnation, it was dried for 10 minutes in a hot air drier at an internal temperature of 150° C. to obtain a humidified filter medium.

Embodiment 2

[0065] Except that the non-woven substrate is used with an internal bond strength of 246mJ and a weight per unit area of 94g / m 2 PET: rayon = 50:50 (dry mass ratio) spunlace non-woven fabric as the non-woven fabric base material, other use the same method as Example 1 to obtain the humidification filter medium.

Embodiment 3

[0067] Except that the non-woven substrate is used with an internal bond strength of 394mJ and a weight per unit area of 95g / m 2 PET: rayon = 50:50 (dry mass ratio) spunlace non-woven fabric as the non-woven fabric base material, other use the same method as Example 1 to obtain the humidification filter medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com