Mould pressing corrugated type flexible flame isolation device

An isolation device, corrugated technology, applied in the direction of rocket engine device, jet propulsion device, machine/engine, etc., can solve the problems of after-effect reverse roll, destructive effect, etc., achieve good comprehensive performance, and meet the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

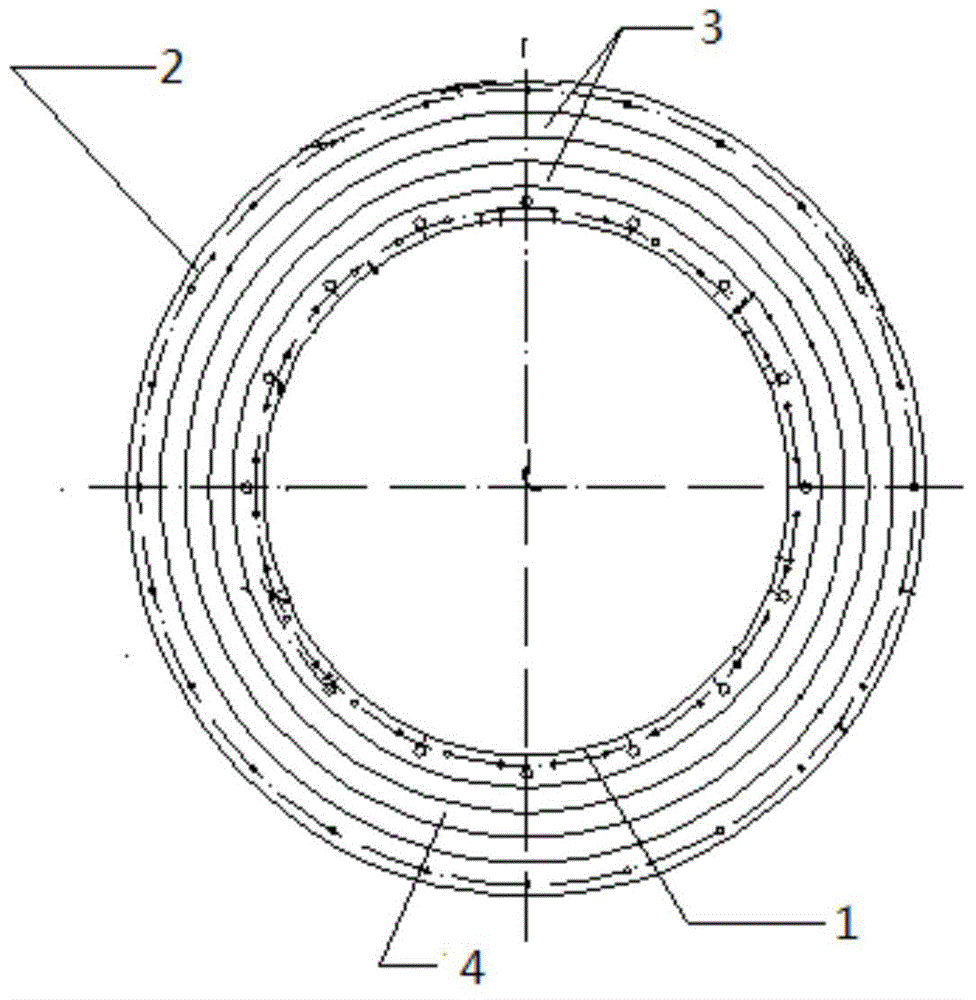

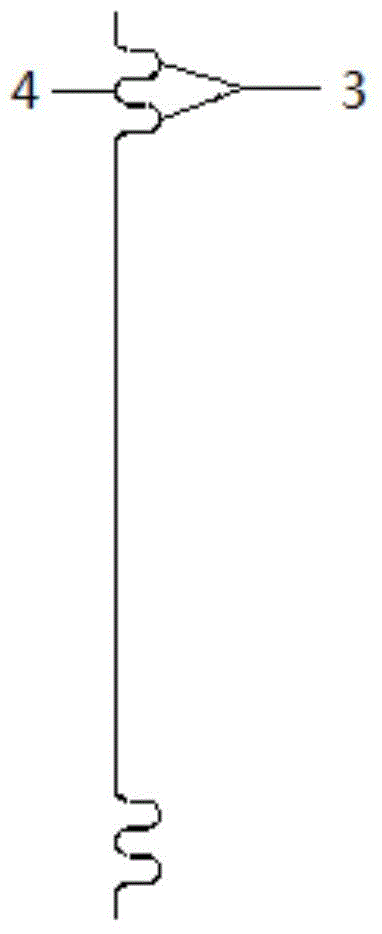

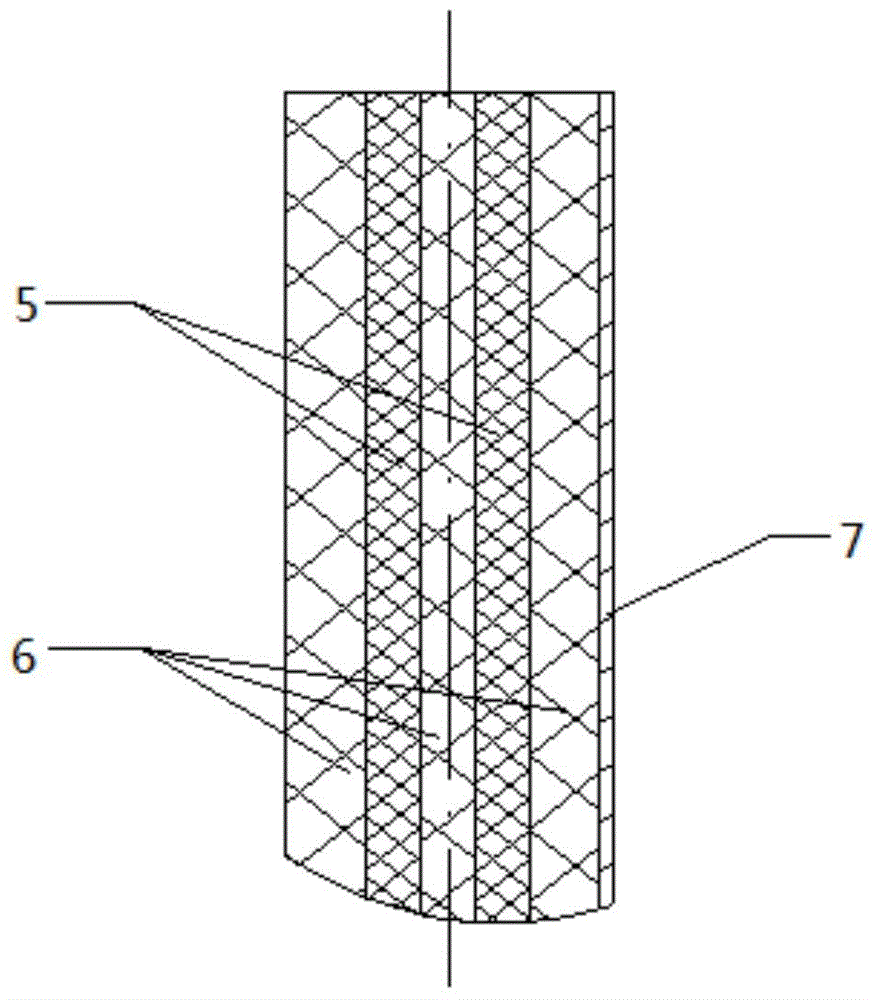

[0020] Such as figure 1 As shown, a molded corrugated flexible flame isolation device has a ring-shaped structure as a whole, and an inner trimming edge 1, an outer trimming edge 2 and a corrugated structure are arranged on the annular structure. The inner trimming edge 1 is located at the innermost side of the annular structure, and the inner trimming edge 1 is fixedly connected with the nozzle flange of the rocket engine. The corrugated structure is located outside the inner trimming edge 1 . The outer trimming edge 2 is located outside the corrugated structure, and the outer trimming edge 2 is fixedly connected with the lower end surface of the rocket tail cabin. The inner trim 1 is used to closely fit the rocket engine, the outer trim 2 is used to closely fit the rocket tail compartment, and the corrugated structure is used to provide space for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com