LED (Light Emitting Diode) lamp

A technology of LED lamps and lamp holders, which is applied in the direction of lighting devices, cooling/heating devices of lighting devices, light sources, etc., and can solve the problem of uneven distribution of light emitted by light emitting units on the surface of the lamp housing, uneven distribution of brightness on the surface of the lamp housing, and heat dissipation effects. Poor and other problems, to achieve uniform brightness, improve the brightness of the irradiation, increase the effect of heat dissipation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

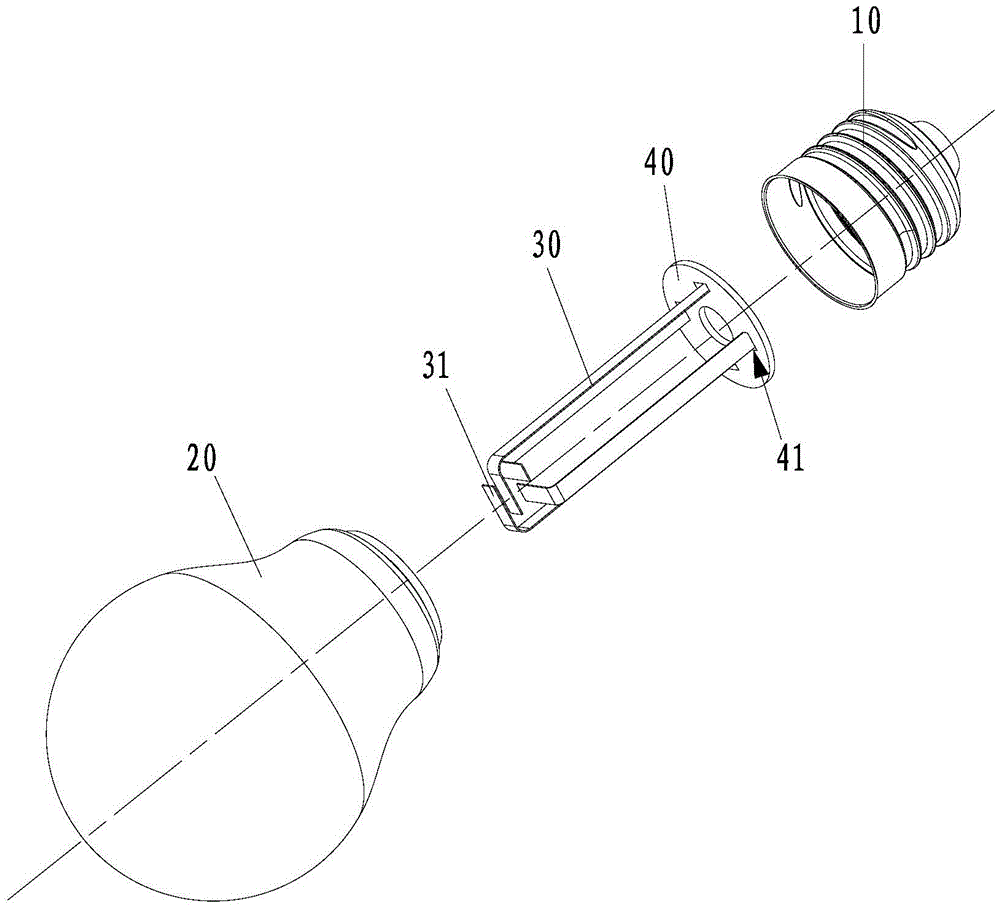

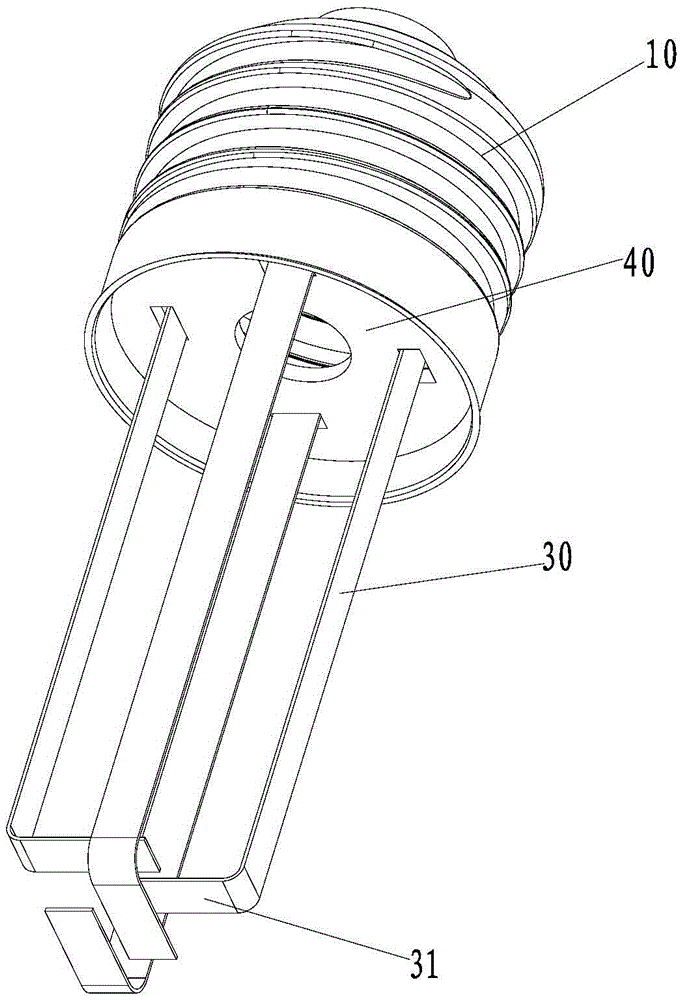

[0022] Embodiment one, consult figure 1 and figure 2 :

[0023] A kind of LED lamp, it comprises lamp base 10, lamp shell 20, drive circuit board (not shown in the figure) and light-emitting unit, light-emitting unit is placed in lamp shell 20, drive circuit board is placed in lamp base 10, lamp base 10 and lamp The housing 20 is detachably connected; the light-emitting unit includes a plurality of elongated light-emitting strips 30, which are parallel to the central axis of the lamp housing 20 and arranged at intervals around the central axis. One end of the light-emitting strips 30 is fixed to the lamp holder 10 and Connect to the driver circuit board. The light emitting strip 30 includes a carrier and LED dies, and the LED dies are evenly arranged on the carrier. In this embodiment, the carrier is in the shape of a strip. Preferably, the luminous strips include more than four, so as to ensure sufficient luminous brightness of the LED lamp.

[0024] In this embodiment, ...

Embodiment 2

[0029] The difference between the second embodiment and the first embodiment is that: the light-emitting strip is a straight strip. The light emitted by the light-emitting strips of this structure can be emitted in a 360-degree direction perpendicular to the central axis, and the brightness on the surrounding surfaces of the lamp housing is uniform, which improves the illumination brightness of the light-emitting unit; The heat dissipation space is increased, so the heat dissipation performance of the light emitting unit and the LED lamp is improved. However, there is no bare LED crystal at the end of the lamp housing away from the lamp cap, so the lack of light at the end of the lamp housing away from the lamp cap leaves a shadow position, which reduces the overall performance of the LED lamp to a certain extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com