Detection tool for combined automobile instrument

A combined instrument and automobile technology, applied in the direction of instruments, measuring devices, and mechanical devices, can solve the problems of low detection efficiency and ineffective control of precision, and achieve the effect of real data, convenient and fast mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

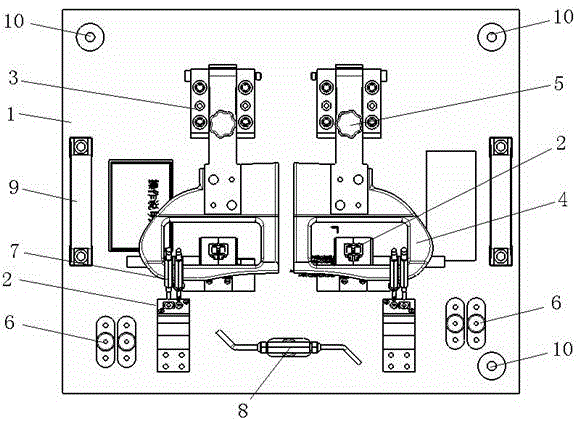

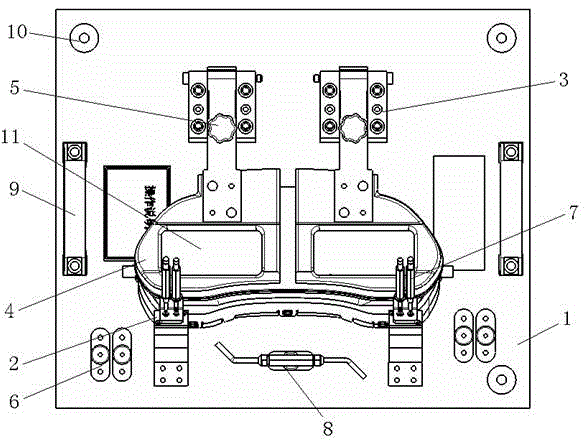

[0020] like figure 1 As shown, the inspection tool of the automobile combination instrument of the present embodiment includes a base plate 1, and four protruding reference blocks 2 are arranged on the base plate 1, and the top surface of the reference block 2 is a reference plane; There are four positioning holes; the key point is that the base plate 1 is provided with a support block 3, and the support block is pivotally connected with a contour surface detection cover 4 through a rotating shaft, and the contour surface detection cover 4 is provided with the actual vehicle and the waiting area. Contour surfaces and / or structural parts that match the automotive instrument cluster.

[0021] The contour detection cover plate 4 is threadedly fitted with a knob 5 , the bottom end of the knob 5 is a stud, and the support block is provided with a screw hole below the stud.

[0022] The above-mentioned reference block 2 includes a main reference block and an auxiliary reference blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com